Rough crack flow guide capability test experiment device and test evaluation method

A technology of conductivity and experimental equipment, which is applied in the direction of measuring equipment, suspension and porous material analysis, instruments, etc., can solve the problems of lower test accuracy and limit the scope of data application and analysis, and achieve the effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

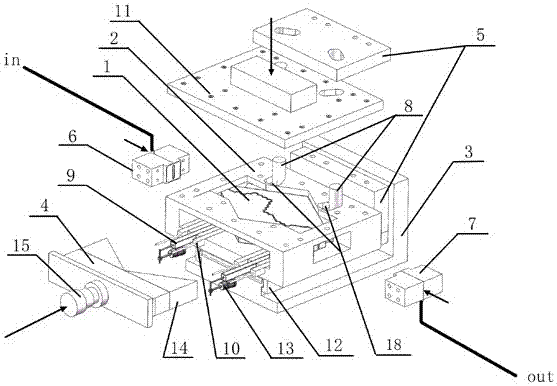

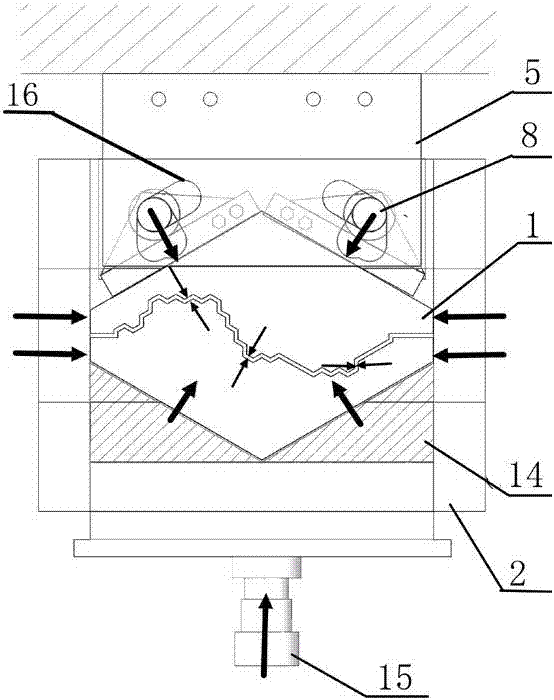

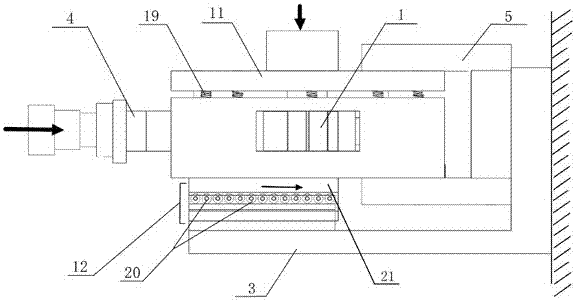

[0032] The present invention will be further explained below in conjunction with the drawings:

[0033] Such as figure 1 As shown, the experimental device for testing the conductivity of rough fractures with fractal features includes a diversion chamber 2, a base 3, a closed pressure loading block 4, a closed pressure regulating device 5, an inlet loading block 6, and an outlet loading block 7. The diversion chamber 2 is provided with a direction-changing loading block 8, which cooperates with the closed pressure loading block 4 and the closed pressure adjusting device 5 to apply closing pressure to the test rock sample 1; there are 6 square grooves in the lower part of the diversion chamber 2, each Install 2 crack width measuring devices 9 and 4 flow pressure measuring devices 10 alternately to measure the crack width and fluid pressure in the cracks during the experiment; the diversion chamber 2 of the test rock sample 1 is installed on the base 3 On the platform 12 with roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com