Enterprise supply chain management system

A supply chain management and enterprise technology, applied in the enterprise operation control method and system field in the enterprise supply chain management system, can solve the problem of not being able to accurately grasp the production and manufacturing site capacity status and material purchase schedule, low realization of intelligent manufacturing, and high cost. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

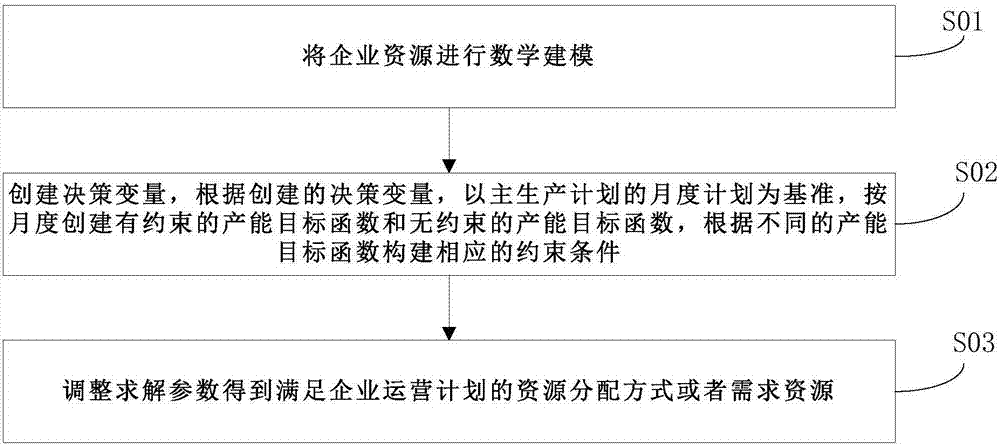

[0048] like figure 1 As shown, an enterprise operation control method in an enterprise supply chain management system includes the following steps:

[0049] S01: Mathematical modeling of enterprise resources;

[0050] S02: Create a decision variable, based on the created decision variable, based on the monthly plan of the master production plan, create a constrained capacity objective function and an unconstrained capacity objective function on a monthly basis, and construct corresponding constraints according to different capacity objective functions ;

[0051] S03: Adjust the solution parameters to meet the resource allocation method or demand resources of the enterprise operation plan.

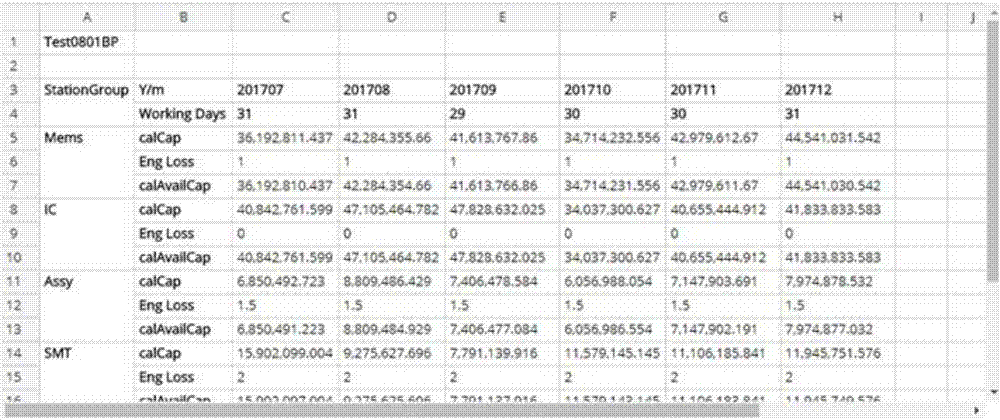

[0052] In step S01, perform mathematical modeling on factory-related production factors and resources, such as equipment data, product data, process data, production capacity data, product-process-equipment data, product yield, etc. Mathematical modeling includes building sets and paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com