Mixed-type permanent magnetic pole rotor

A permanent magnetic pole and mixed type technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit, magnetic circuit shape/style/structure, etc., can solve the problems of easy demagnetization of magnetic steel and insufficient utilization of torque output magnetic steel, etc. Achieve the effect of reducing the weight of the rotor and increasing the torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

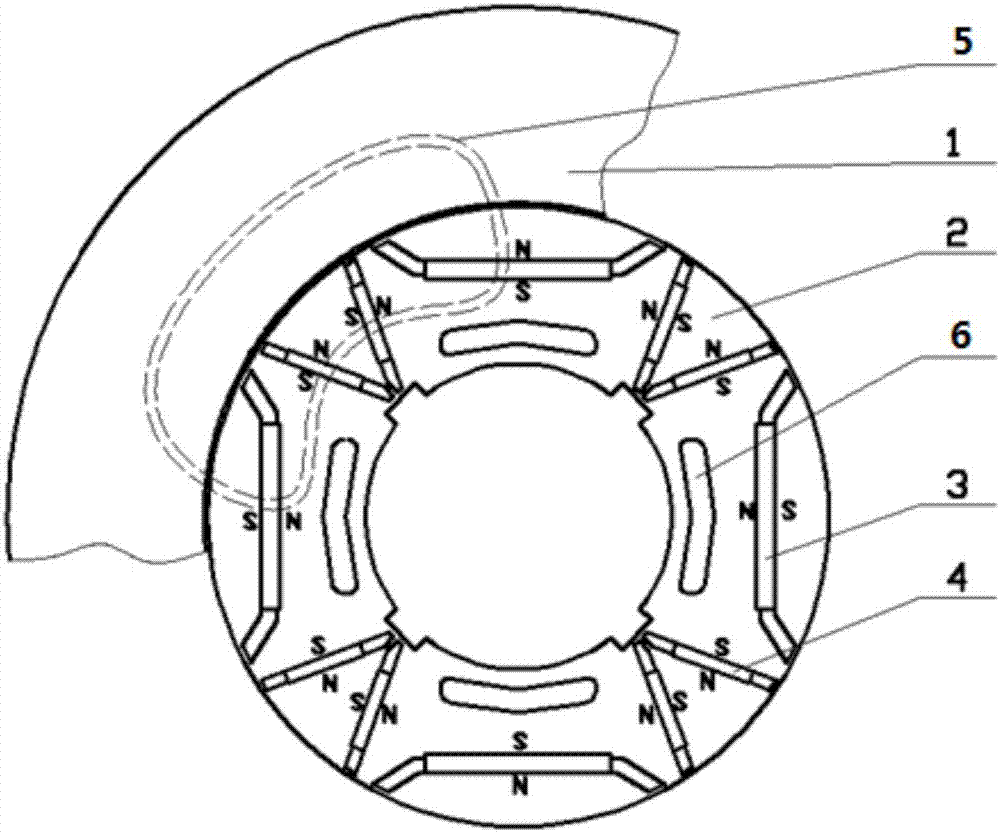

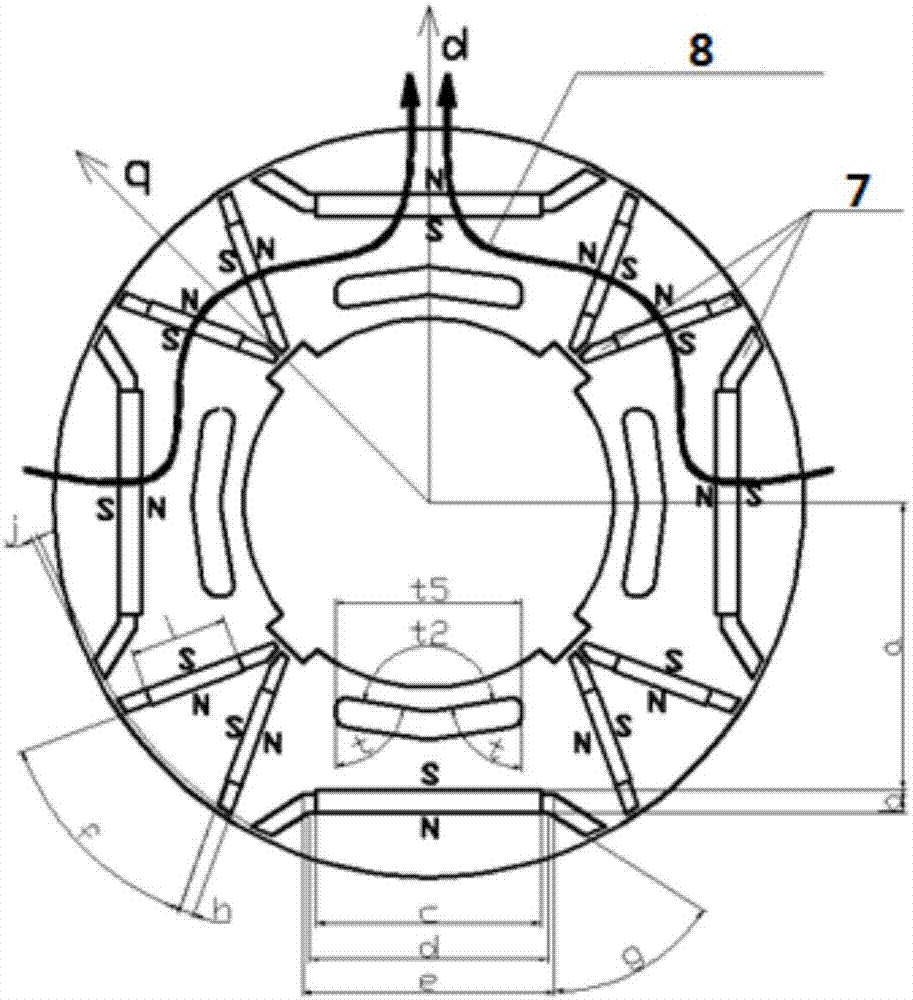

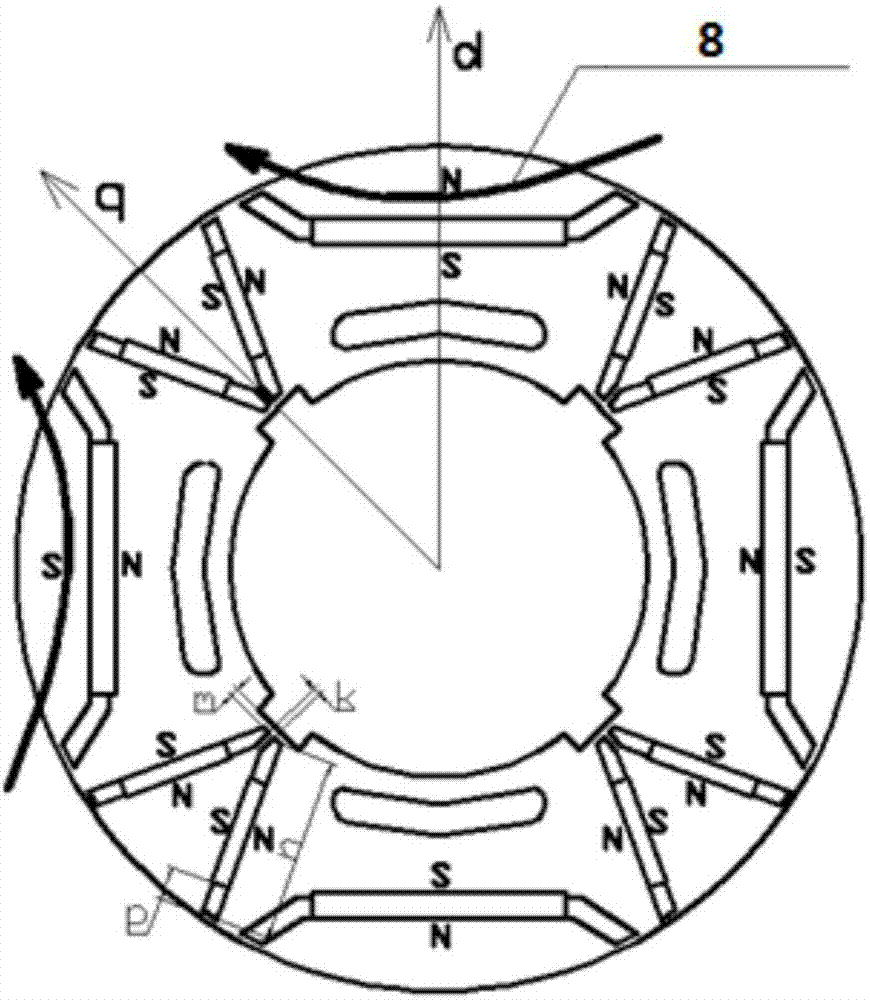

[0023] as attached figure 1 : The present invention provides a hybrid permanent magnet pole rotor structure, each pole magnetic steel is arranged in a shape such as a straight and V-shaped combination, "one" is 1 magnetic steel, which is a radial magnetic field, and "V" is 2 magnetic steels , is the tangential magnetic field. The N and S orientations of the magnets corresponding to the two adjacent poles are opposite. Between the "V" of the pole and the pole, a weight-reducing groove 6 of a certain size and shape is designed at an appropriate position.

[0024] This kind of rotor structure can be made into 4 poles, 6 poles, 8 poles... For the 4 pole rotor structure, twelve magnetic steel slots, twenty-four magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com