Explosion-proof lighting control box and control method thereof

A technology for lighting control and lighting lamps, applied in lighting devices, energy-saving control technology, light sources, etc., can solve the problems of wasting labor costs, energy waste, single function, etc., to improve the degree of automation and operation reliability, and achieve good energy-saving effects. Control flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

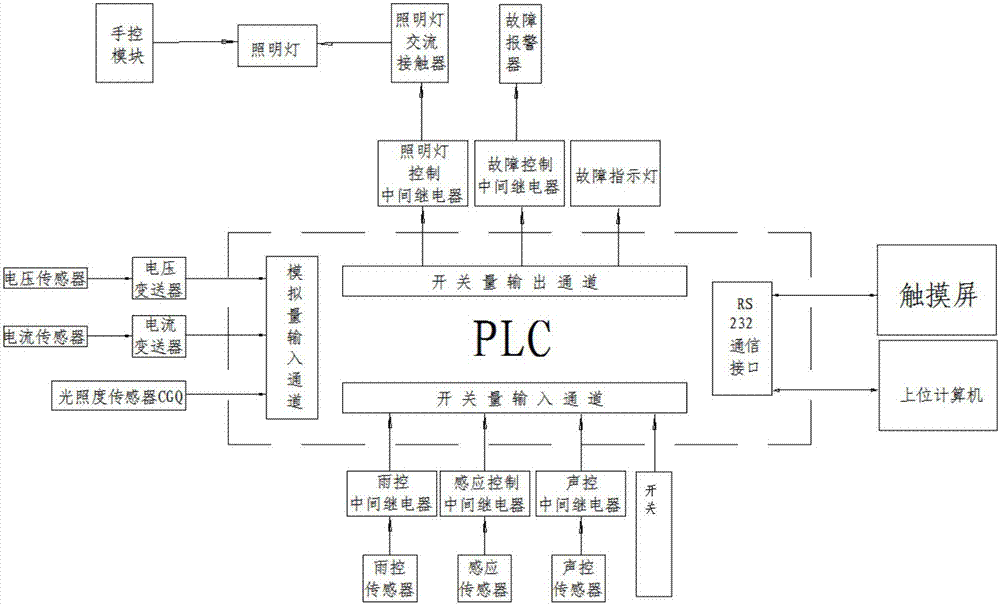

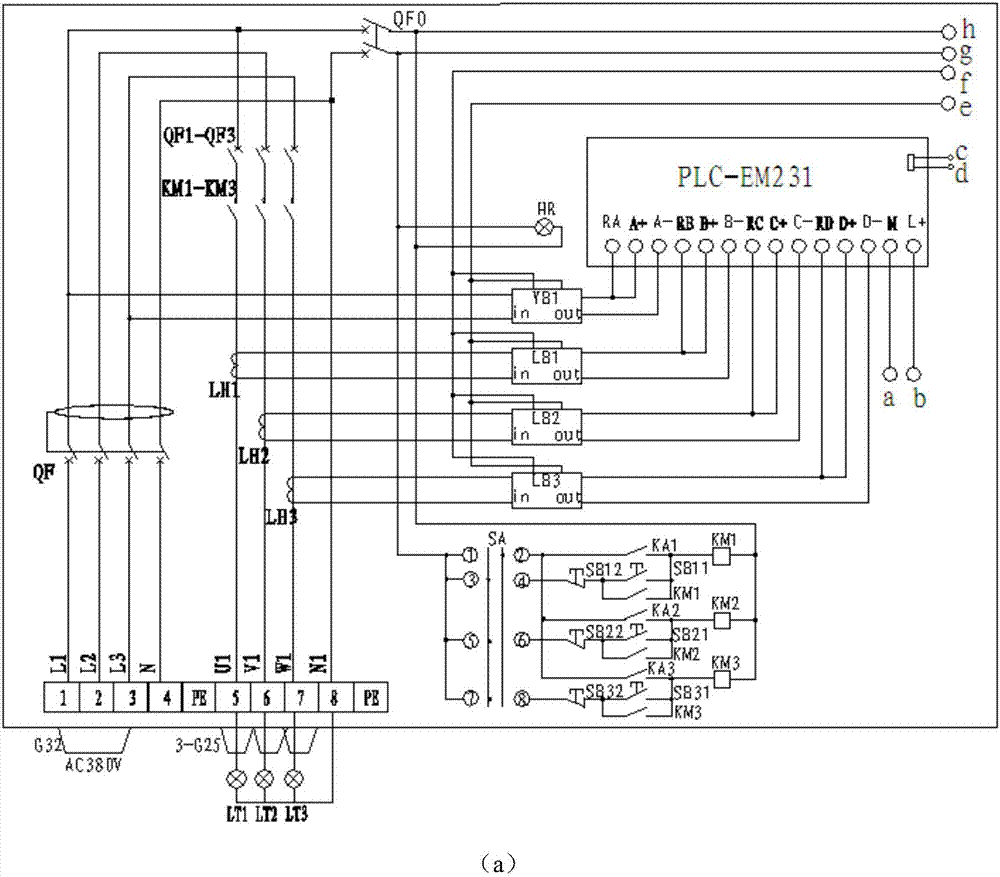

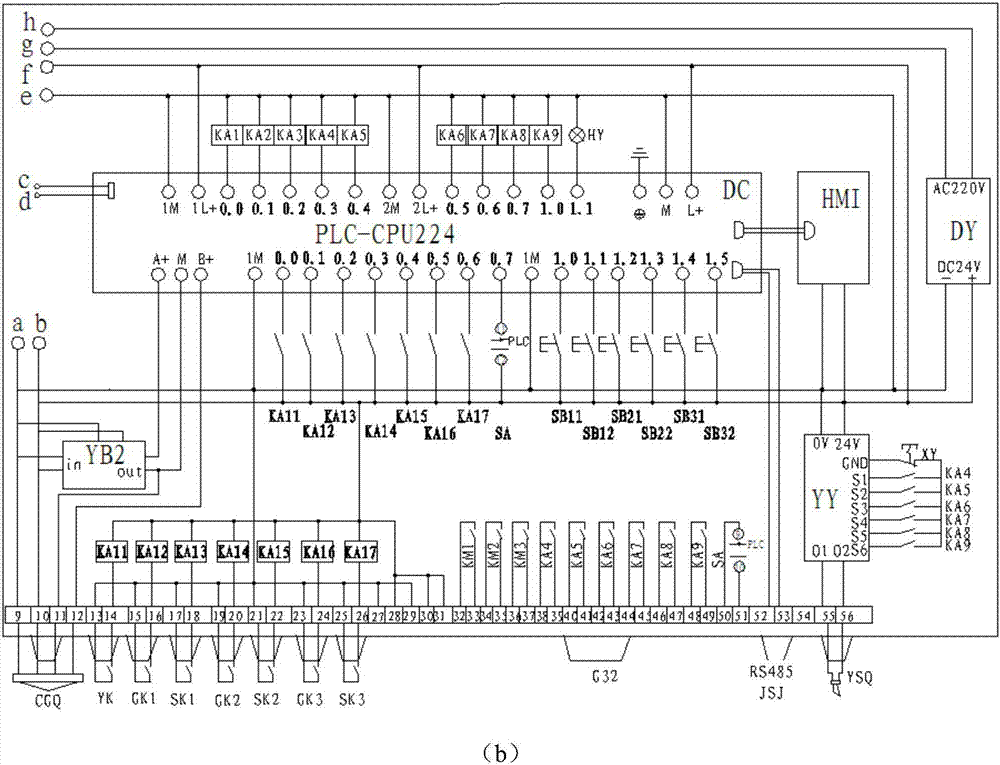

[0050] The explosion-proof lighting control box of this embodiment is a distribution box that detects, controls, and supplies power to the lighting circuit. It can be installed in any non-explosion-proof, explosion-proof single-phase or three-phase lighting control electrical circuit in various industries. In, to achieve the control of the lighting system. It can not only be used to control outdoor lamps, but also can be used in intelligent explosion-proof lighting control in various indoor environments. Taking the control of three groups of lighting lamps LT1-LT3 as an example to illustrate this explosion-proof lighting control box, such as figure 1 and figure 2 shown, including:

[0051] Cabinet, switching power supply DY installed in the cabinet, AC voltage transmitter YB1, DC voltage transmitter YB2, current sensor LH1-LH3, current transmitter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com