Selected grain thresher

A thresher and threshing mechanism technology, which is applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of affecting the winnowing effect, single power configuration form, and small cultivated land area, so as to reduce the dust pollution area and improve Screening efficiency, effect of increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

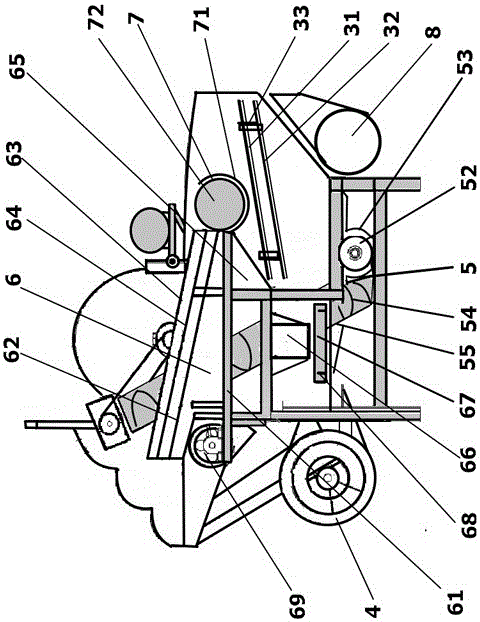

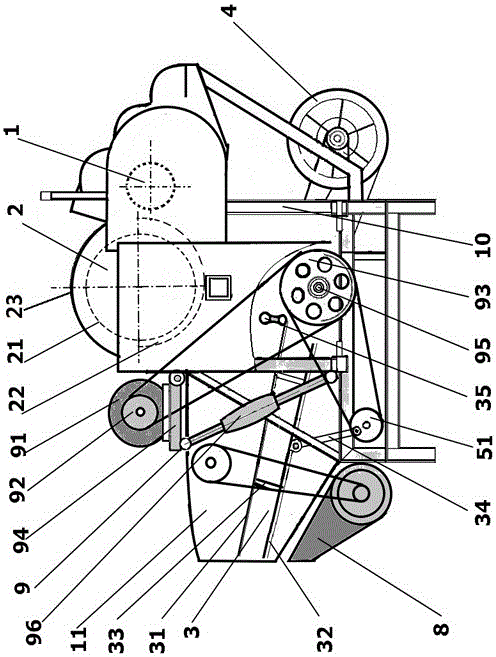

[0014] Such as figure 1 , 2 As shown, the present invention comprises frame 10, feeding mechanism 1, crushing and threshing mechanism 2, winnowing device 11, shaking screen mechanism 3, main blower 4, auxiliary blower 8, electric power source mechanism 9, transport mechanism 5, two Secondary cleaning device 6, return mechanism 7, transmission mechanism, feeding mechanism 1 and crushing and threshing mechanism 2 are installed on the frame 10 respectively, and feeding mechanism 1 feeds wheat draft to crushing and threshing mechanism 2; A winnowing device 11 is provided, and a vibrating sieve mechanism 3 is arranged in the winnowing device 11, and the wheat manuscript crushed by the crushing and threshing mechanism 2 falls on the shaking sieve mechanism 3, and is screened and cleaned through two layers of sieves to strengthen the screening effect; The main blower 4 is arranged at the position below the feeding mechanism 1 behind the frame 10, and provides wind power to the shaki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com