Binding machine for gardening

A strapping machine and gardening technology, applied in gardening, strapping machinery parts, strapping objects, etc., can solve the problem of not knowing how much the handle is held, the grip is shallow, etc., and achieve simple and reliable control of the amount of grip Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

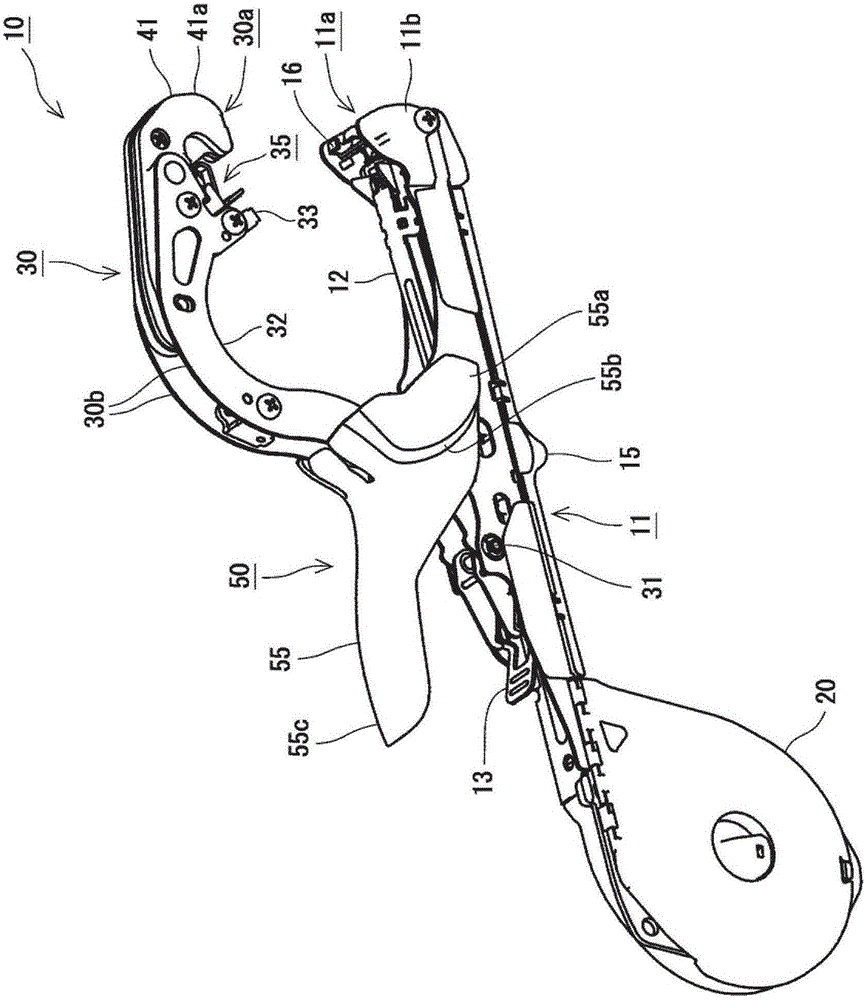

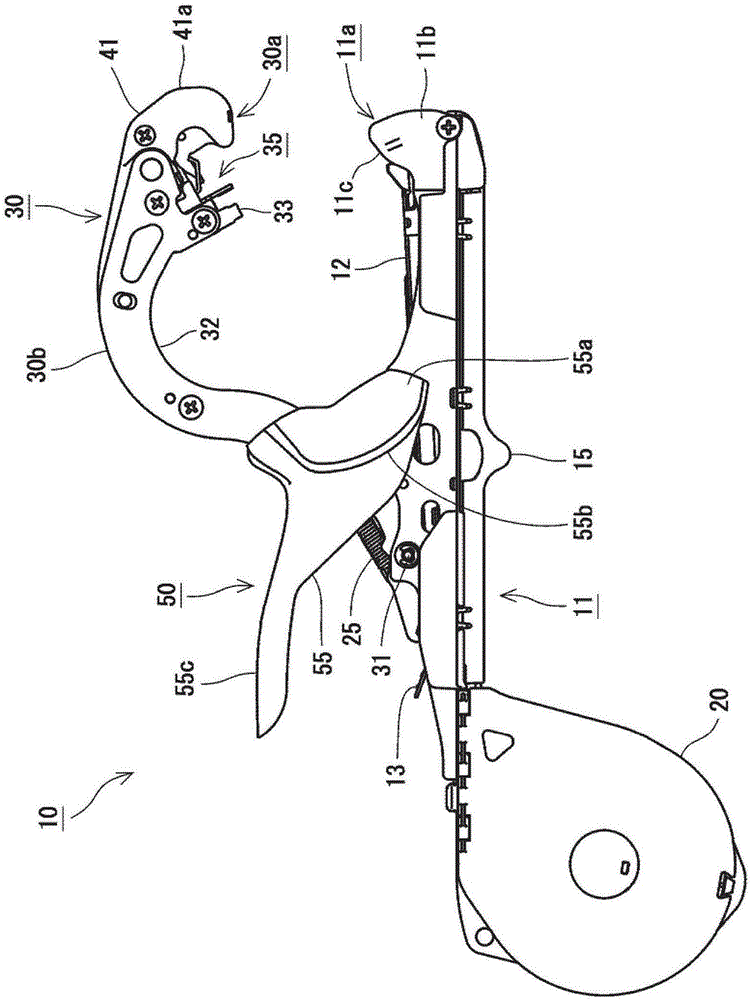

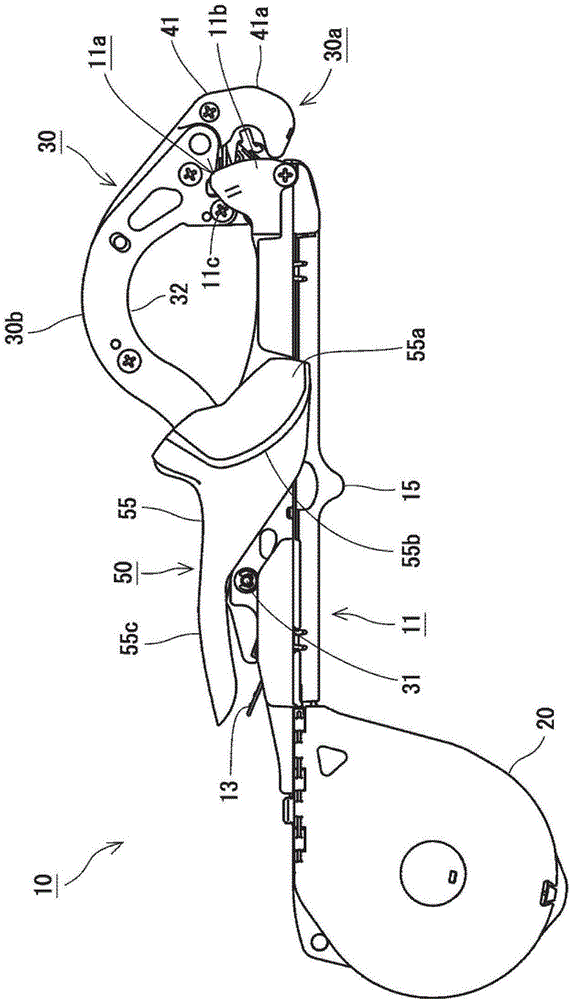

[0110] The embodiments of the present invention will be described with reference to the drawings. It should be noted that in the following description, the front refers to the direction facing the object to be tied S when the gardening strapping machine 10 is in use ( figure 2 The right direction in the middle), the back refers to the opposite direction of the front ( figure 2 In the left direction).

[0111] The gardening strapping machine 10 of this embodiment is used to guide the strapping operation in crop cultivation, such as Figure 1~3 As shown, the main handle 11 is linearly elongated, the gripper arm 30 is installed to be rotatable relative to the main handle 11, and the operation handle 50 is installed to be rotatable relative to the gripper arm 30. Such as Figure 4 As shown, the clincher arm 30 is always urged by the tension spring 25, and is in an open state with respect to the main handle 11 in the normal state. By holding the operating handle 50 and the main hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com