Heavy aluminum profile stretching straightener

A technology of stretching straightening machine and aluminum profile, which is applied in the field of metallurgical equipment, can solve the problems of heavy moving parts, impact of equipment and hydraulic system, large cross-sectional size of aluminum profile, etc., and achieve the effect of improving service life and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

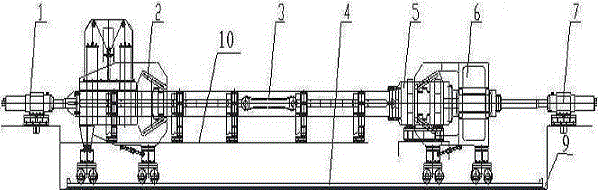

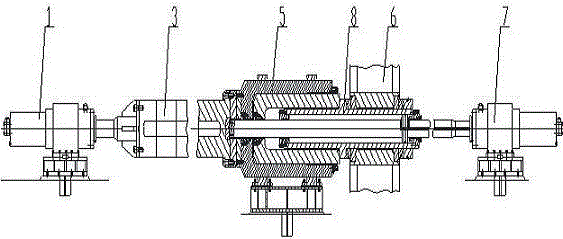

[0019] This embodiment provides a kind of heavy-duty aluminum extrusion straightening machine, comprising equipment foundation 9, main stretching oil cylinder 5, frame 3 located on equipment foundation 9, stretching head 6 and tailstock 2, stretching head 6 and the tailstock 2 are arranged at the two ends of the frame 3 respectively, the stretching head 6 and the tailstock 2 are provided with jaws, the frame 3 can move along the stretching direction relative to the equipment foundation 9, and the main pull Stretching oil cylinder 5 is located between frame 3 and stretching head 6, and the cylinder tail of this main stretching oil cylinder 5 is supported on frame 3 front ends, and the other end withstands stretching head 6, and described tailstock 2 and frame 3 rigidly connected, the stretching head 6 and the tailstock 2 are all slidably connected with the equipment foundation 9.

[0020] like figure 1 As shown, when the heavy-duty aluminum profile stretching straightener is s...

Embodiment 2

[0025] On the basis of Embodiment 1, this embodiment provides a heavy-duty aluminum extrusion straightening machine, the equipment foundation 9 is provided with a sliding support 10 and a guide rail 4, and the frame 3 is located on the sliding support 10, the stretching head 6 and the tailstock 2 are all provided with traveling wheels that cooperate with the guide rail 4.

[0026] The jaws are inclined pair of clamps, and the included angle with the horizontal direction is 20-25°. Ensure that the profile will not slip when stretched.

[0027] It also includes an idle stroke buffer oil cylinder 8, the main stretching oil cylinder 5 is a plunger cylinder, the tail of the empty stroke buffer oil cylinder 8 is fixedly connected with the stretching head 6, and one end of the piston rod passes through the main stretching oil cylinder 5 and the machine. Frame 3 is connected.

[0028] It also includes a buffer reset oil cylinder 1 and a frame positioning oil cylinder 7, the buffer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com