A small curvature bending forming auxiliary processing device and auxiliary processing method

A bending forming and auxiliary processing technology, applied in the field of auxiliary tooling, can solve the problems of long time, affect the performance of the workpiece, time-consuming, etc., and achieve the effect of convenient disassembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

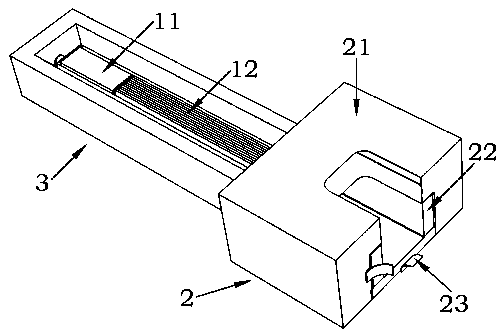

[0029] Such as figure 1 As shown, the small-curvature bending processing auxiliary device includes a mandrel 1 , a support 2 and a guide groove 3 . The periphery of the mandrel 1 is provided with a C-shaped guide groove 3, and one end of the guide groove 3 is also provided with a support 2. The support 2 includes a seat body 21 and a clamping block 22. There is a cavity in the seat body 21 for clamping The block 22 is inside the cavity, and one side and the bottom of the seat body 21 are respectively fixed with a limiting elastic piece 23, and the limiting elastic piece 23 is an arc-shaped, elastic bent metal sheet. The limit shrapnel 23 can limit the position of the workpiece, so that the mandrel 1 can be inserted into the workpiece more accurately and smoothly, and the clamping block 22 can clamp the workpiece when the workpiece is bent.

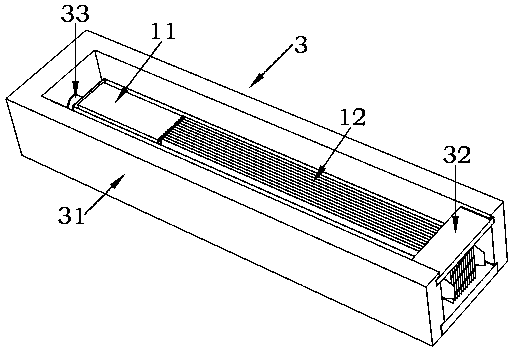

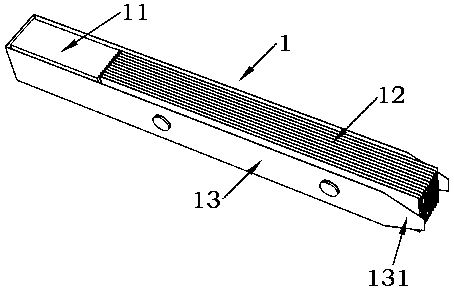

[0030] Such as figure 2 and image 3 As shown, the mandrel 1 is embedded in the guide groove 3, and the guide groove 3 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com