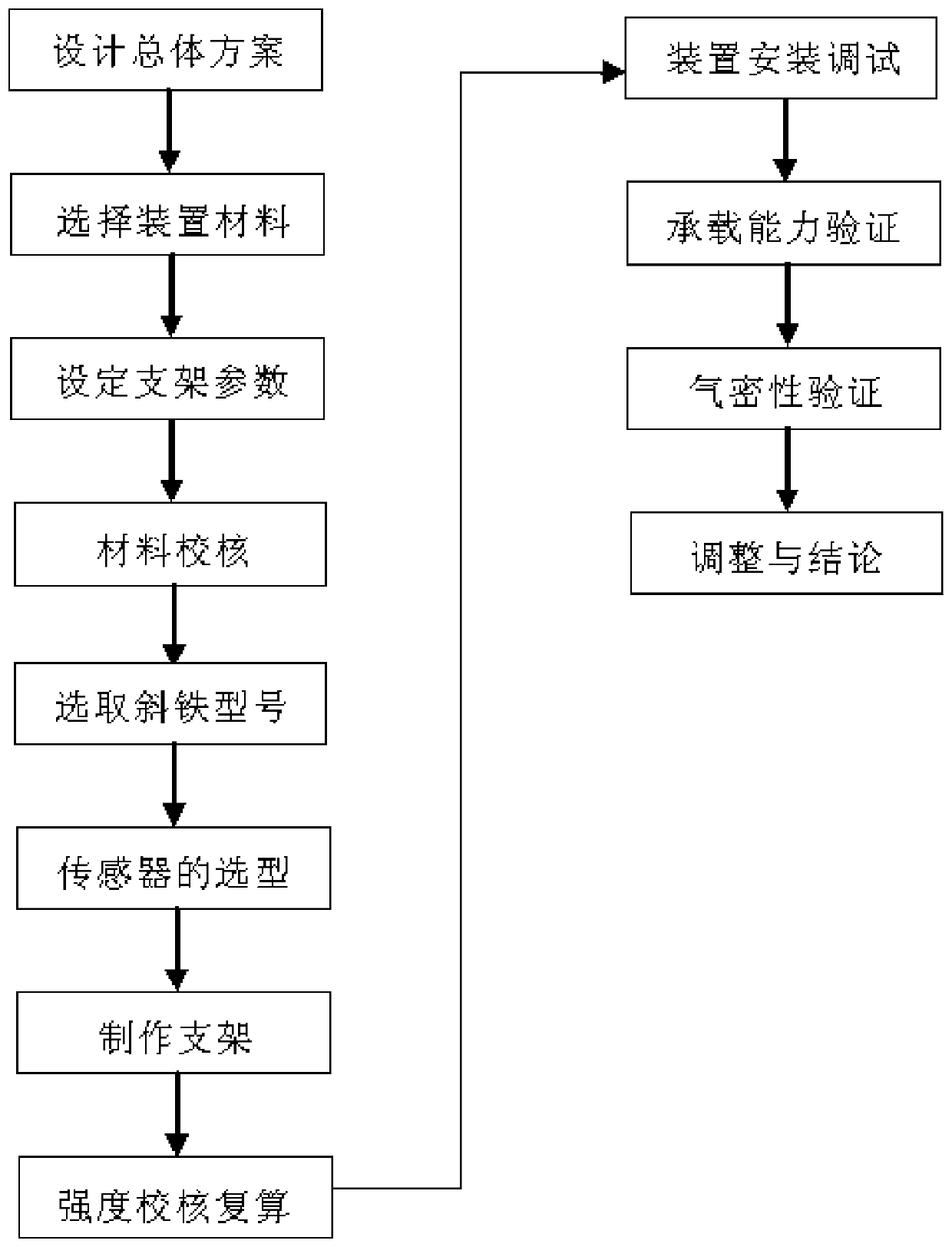

A low-pressure casting bearing conversion device for large-scale castings and its manufacturing method

A technology of low-pressure casting and large-scale castings, which is applied in the field of low-pressure casting load-bearing conversion devices for large-scale castings and its manufacture, and low-pressure pouring. Market application prospect, cost reduction and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

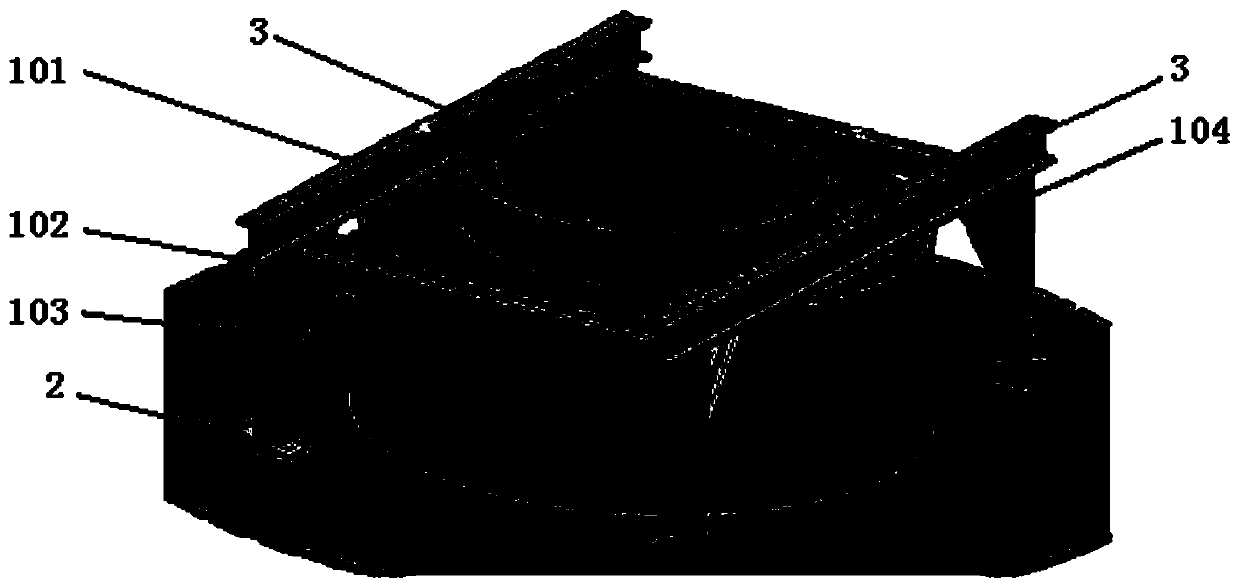

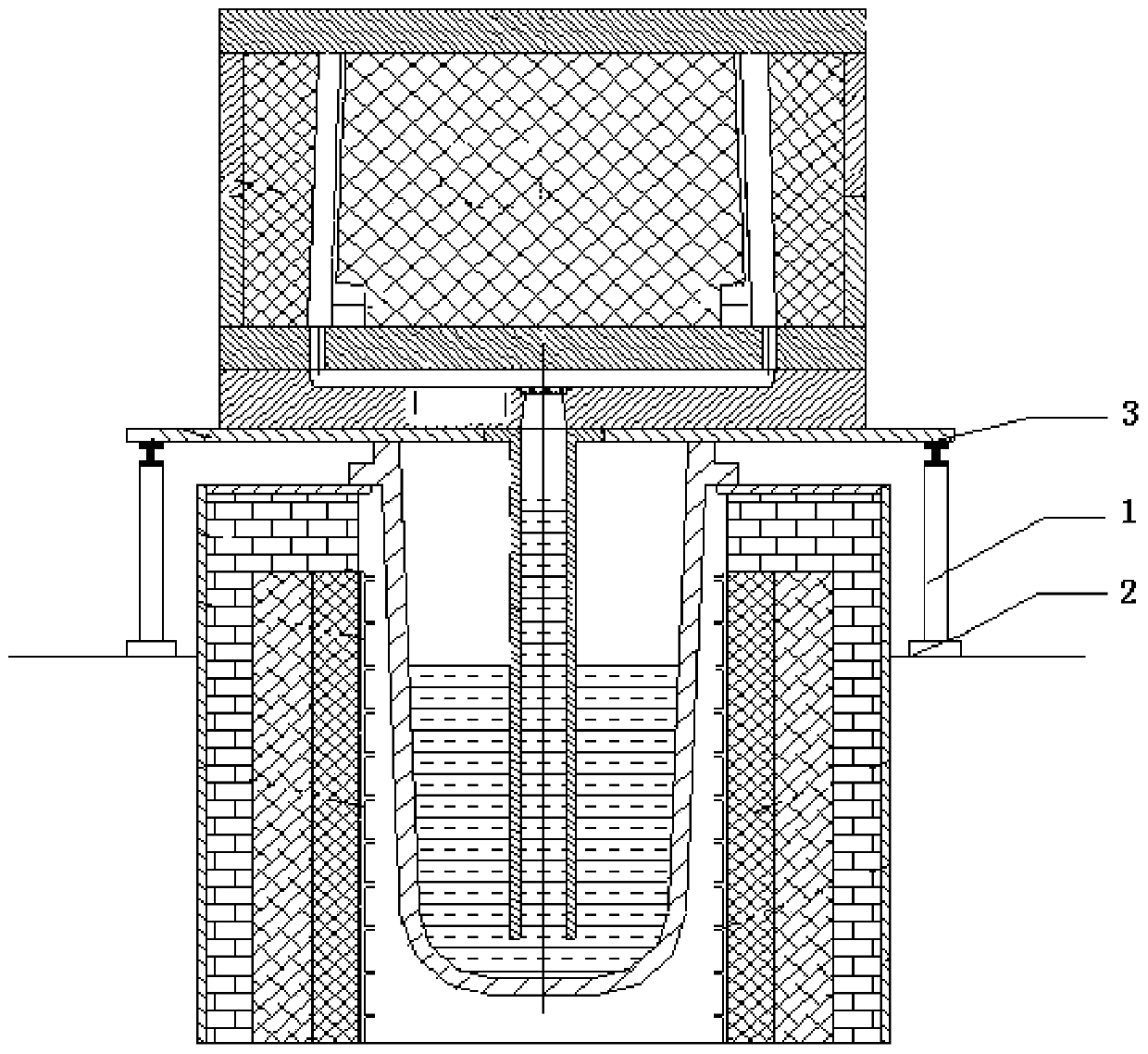

Embodiment 1

[0072] The maximum bearing weight of the existing furnace body in a workshop is 3t, which is suitable for casting small and medium-sized castings. Now it has received a research and development task for a large cabin section. After calculation, the maximum pressure on the furnace body will be as high as 4.5t when pouring this casting. There is a furnace body that cannot be poured.

[0073] The specific parameters of the bracket are determined according to the size of the casting furnace body and crucible in the workshop as follows:

[0074] The distance between the two load-bearing beams 101 is L1=1200mm;

[0075] The overall height of the load-bearing device H1=500mm;

[0076] The distance between the two support beams 102 is L2=1600mm;

[0077] The profiles that meet the conditions are determined by comparing the above parameters with the profile list. Since the I-beam, H-beam and square steel do not satisfy H<100mm, the profile 8# channel steel is selected as the producti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com