Planar three-degree-of-freedom moving platform with large rotation angle

A motion platform and rotary plane technology, applied in the field of robotics, can solve problems such as limited motion space and difficulty in achieving height, and achieve the effect of large working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

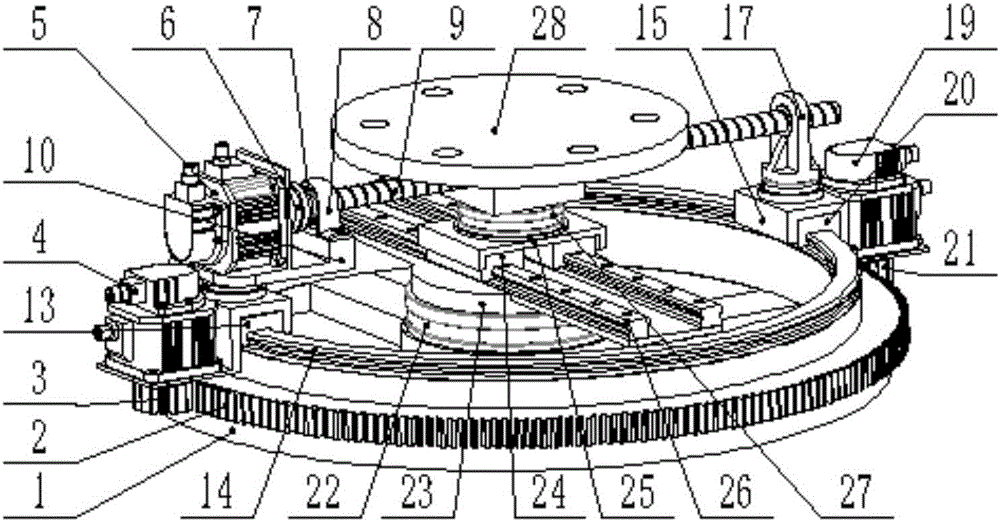

[0017] exist figure 1 In the schematic diagram of the three-degree-of-freedom motion platform shown in the large gyration plane, the support 1 is a spoke structure made of aluminum alloy, the inner ring and the outer ring are connected by 4 plate-like structures, the load-bearing module is set on the inner ring of the support, and the drive module Set on the outer ring of the bracket; the drive module includes a drive module A, a drive module B, a drive module C, an outer ring gear and a circular guide rail, and the steel outer ring gear 2 is fixed on the outer ring of the bracket by bolts On the inner side of the outer ring gear, there is a circular guide rail 14; the drive module A and the drive module B are arranged on the same side of the outer ring gear, and the drive module C is evenly distributed on the outer ring gear;

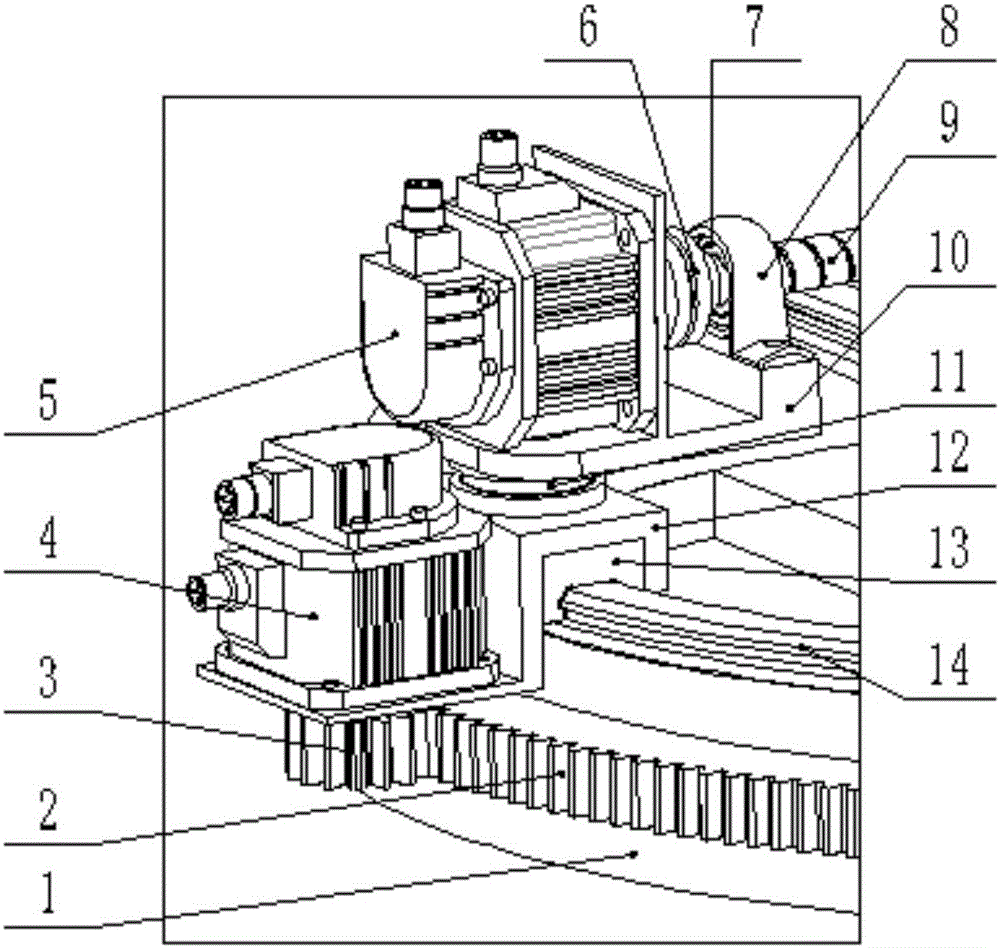

[0018] Such as figure 2 As shown, the motor base A12 in the drive module A is a bow-shaped plate-shaped structure, made of aluminum alloy, one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com