Display screen conveying line

A conveying line and display technology, which is applied to conveyor objects, transportation and packaging, metal processing, etc., can solve problems that affect processing efficiency, poor products, and high labor intensity, so as to ensure synchronization and accuracy, and realize four-sided The effect of position correction and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

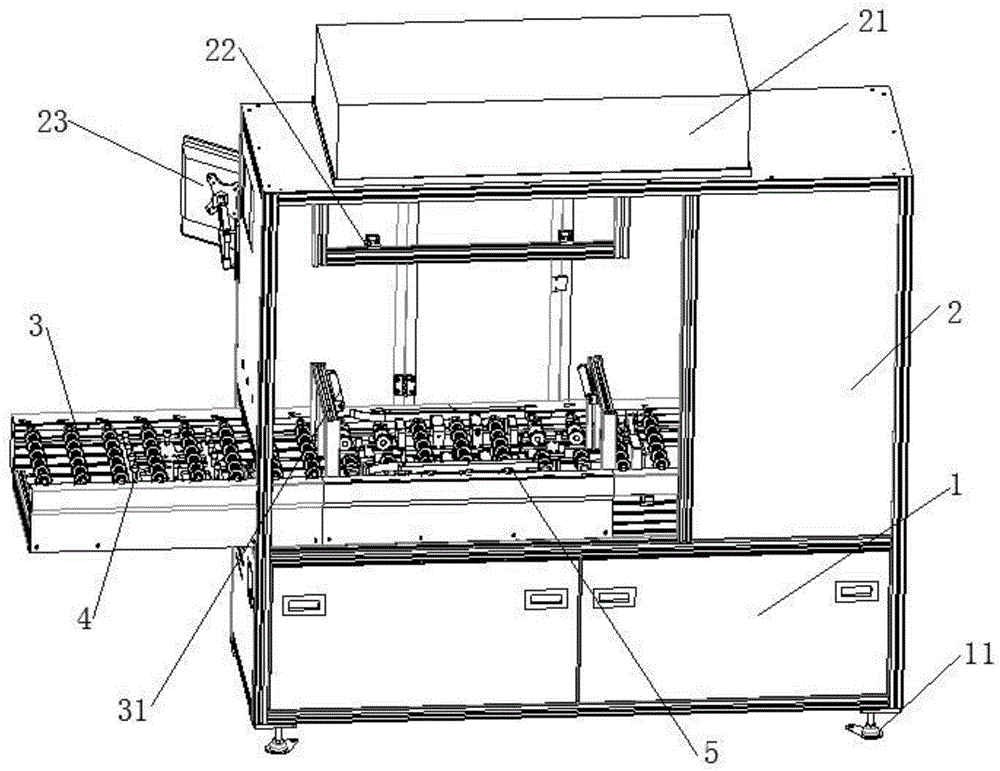

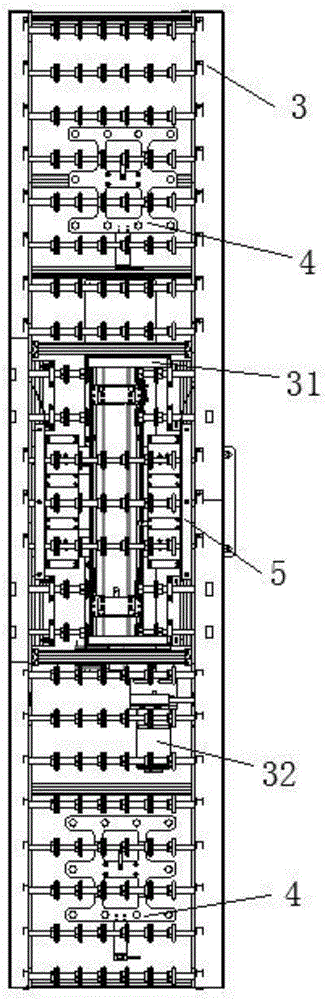

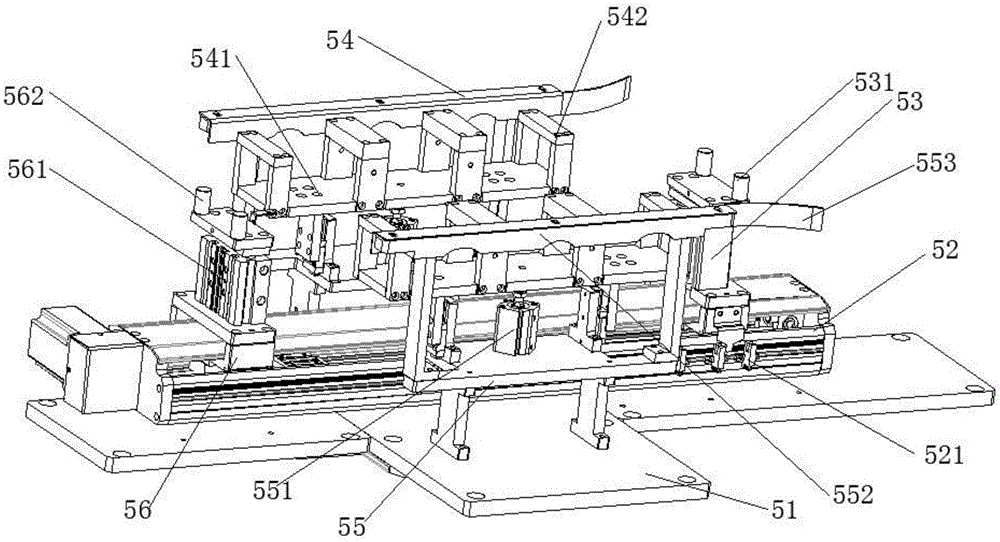

[0023] refer to figure 1 , figure 2 , a display conveyor line, comprising a lower frame 1, a roller conveyor belt 3 and a positioning and correcting device 5, the roller conveyor belt 3 is arranged on the lower frame 1, and the positioning and correcting device 5 is arranged on the roller conveyor belt 3, the lower frame 1 is provided with a driving motor 32 for driving the roller conveyor belt 3, and the driving motor 32 is connected with the roller conveyor belt 3 through a synchronous belt; For the conveyor belt 3, the width of the positioning and correcting device 5 is less than or equal to the width of the roller conveyor belt 3.

[0024] The roller conveyor belt 3 adopts ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap