Method for fixing, hoisting and carrying hydraulic support pushing rod

A technology of hydraulic support and push rod, which is applied in the directions of pillar/support, earthwork drilling, transportation and packaging, etc., can solve the problem of high hanging distance between the support base and the trolley, difficulty in loading and fixing the hydraulic support, equipment damage to personal accidents, etc. problems, to achieve the effect of reducing the lifting height and the difficulty of lifting, increasing the guarantee of safe production, and solving the difficulty of loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The hydraulic support push rod of the present invention is fixed lifting and carrying method is:

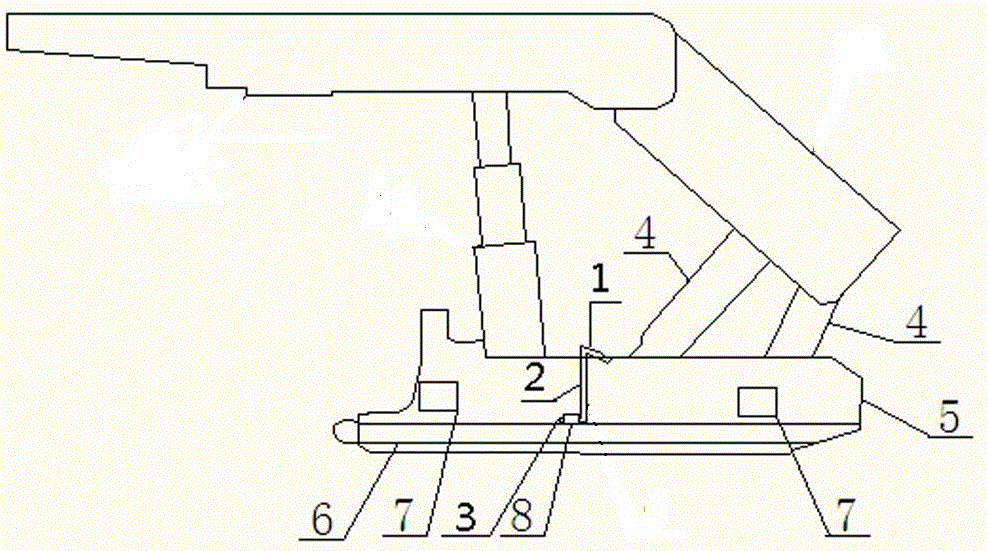

[0016] (1) Lifting and transporting a hydraulic support requires a set of special hook devices, and a set of special hook devices includes two fixing rings 8 and two special fixing hooks. There are two right-angle bends on the special fixed hook. The fixed hook includes upper flat hook 1, vertical bar 2 and lower flat hook 3; between upper flat hook 1 and middle vertical bar 2, between middle vertical bar 2 and lower flat hook 3, The included angle between the upper flat hook 1 and the lower flat hook 3 is a vertical angle of 90 degrees; the upper flat hook 1 is longer than the lower flat hook 3; the fixing ring 2 is a steel pipe that can be inserted into the lower flat hook 3 of the fixing hook;

[0017] (2) Weld two fixing rings 8 to the center points on the left and right sides of the top surface of the hydraulic support push rod 6, at a distance of 1400mm from the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com