Ultrasonic self-cleaning roller washing machine and self-cleaning method

A drum washing machine and ultrasonic technology, applied in other washing machines, oscillating washing machines, washing devices, etc., can solve the problems of bacteria loss, secondary pollution of clothes, etc., to improve the washing effect, improve user satisfaction, and solve the problem of secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

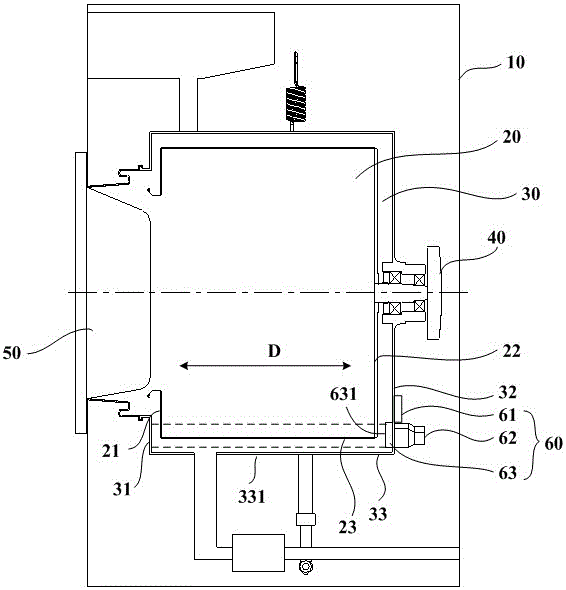

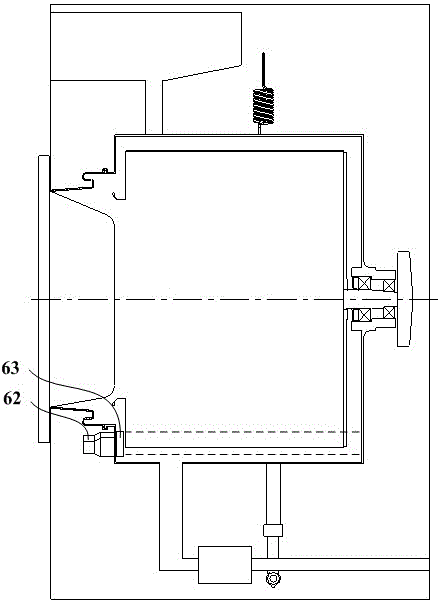

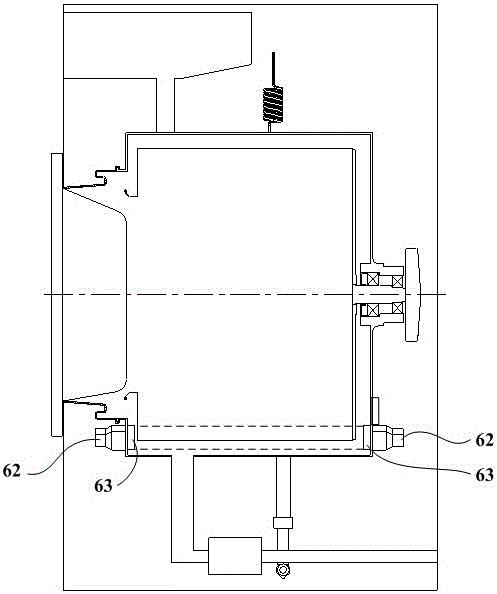

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] Ultrasonic cleaning uses the principle of ultrasonic cavitation to convert electrical energy into ultrasonic vibration mechanical energy under the action of a transducer, thereby generating high-frequency vibrations with extremely small amplitude but high vibration acceleration. After the radiation power reaches a certain level, this high-frequency vibration will generate many tiny bubbles and continue to burst. The bursting of the bubbles will generate shock waves of tens to hundreds of atmospheres in an instant, and then wash away the surface of the product attached by the bubbles.

[0036] At present, ultrasonic cleaning technology has been applied in many industries. According to different cleaning objects, its working frequency is roughly divided into three frequency bands: low-frequency ultrasonic cleaning (20KHz~50KHz), high-frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com