Processing accessories for processing water-based suspended fiber materials

A technology for fiber materials and accessories, which can be used in fiber raw material processing, application, pulp beating/refining methods, etc., and can solve problems such as changes in processing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

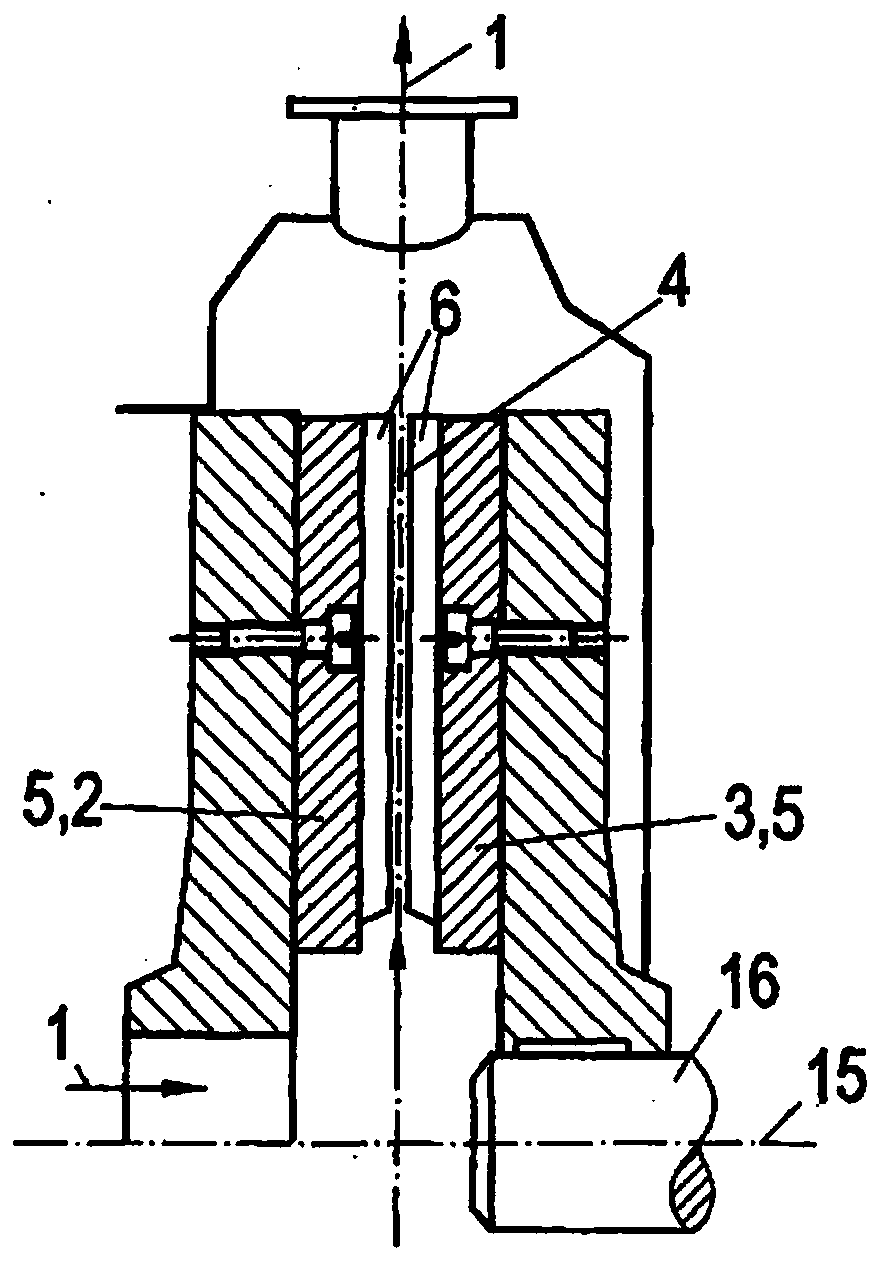

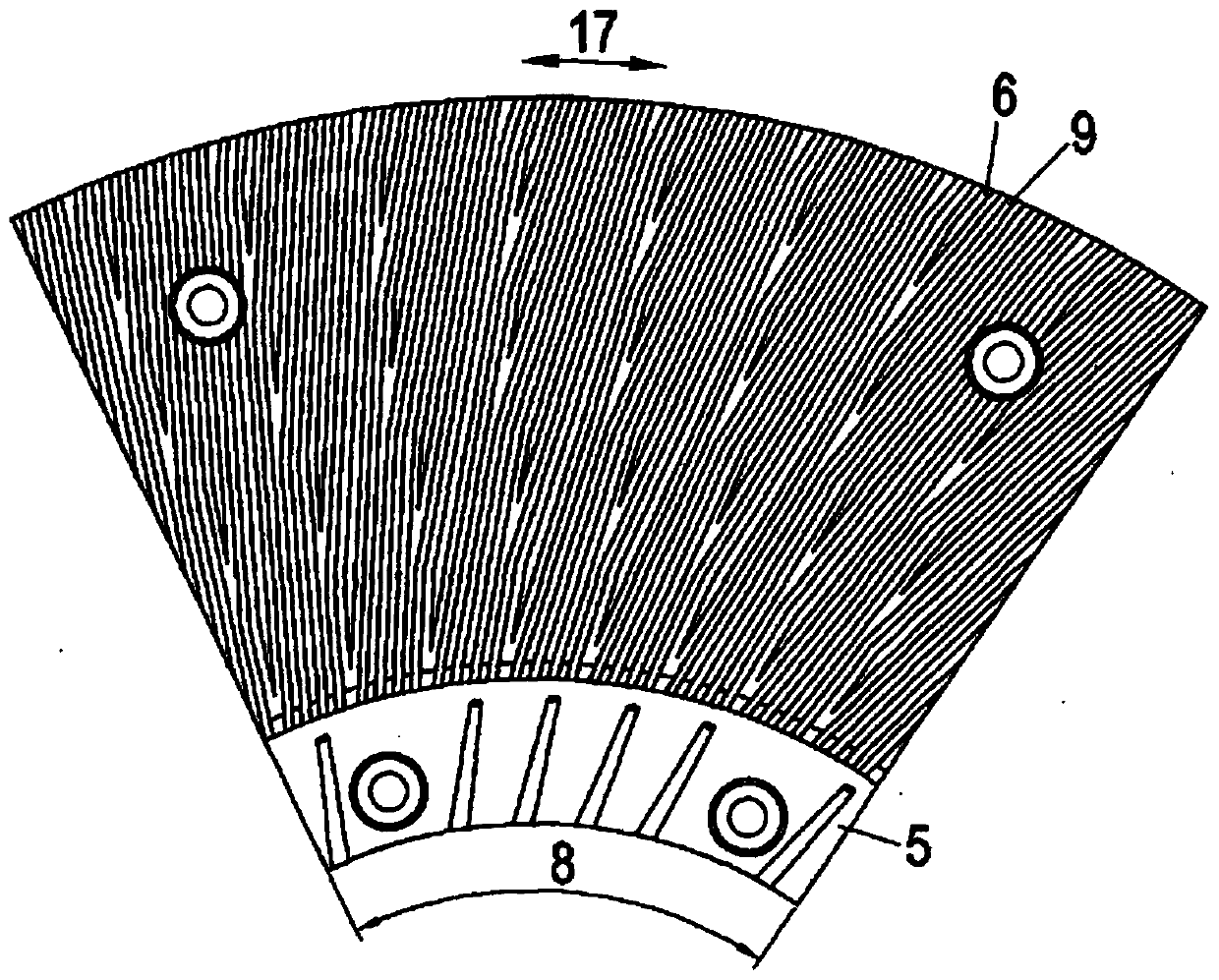

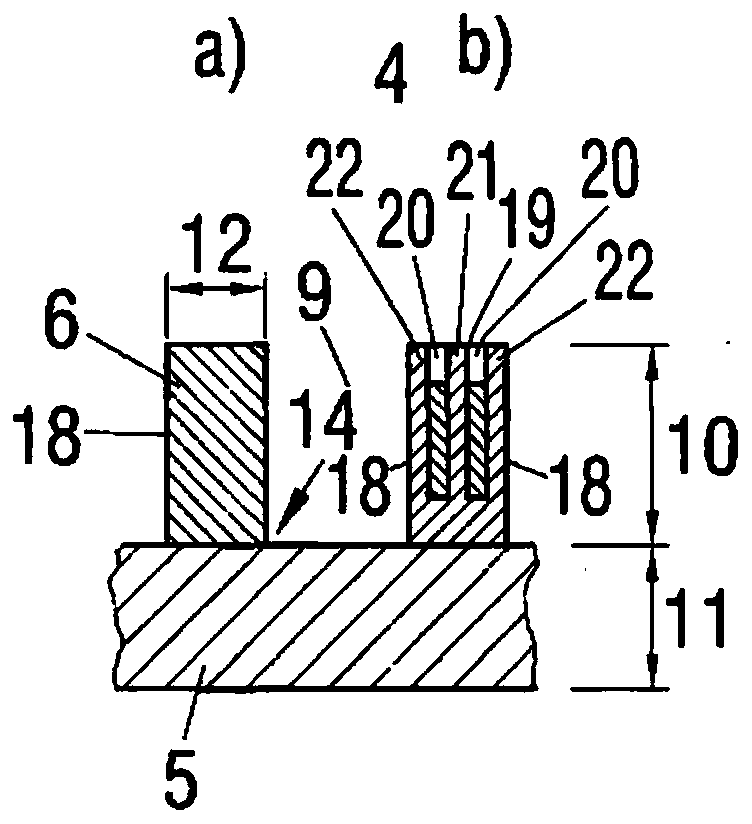

[0046] according to figure 1 , in the housing of the grinding device, the grinding gap 4 is formed by a grinding surface that is fixed and connected to the housing and a grinding surface that rotates around the axis of rotation 15 . In this case, two annular grinding surfaces (processing surfaces) run parallel to one another, wherein the distance between the two grinding surfaces can usually be adjusted.

[0047] In this case, the rotating grinding surface is moved in the direction of rotation via a shaft 16 mounted rotatably in the housing. The shaft 16 is driven by a drive also arranged in the housing.

[0048] In the exemplary embodiment shown, the fiber suspension 1 to be ground enters the grinding gap 4 between the two grinding surfaces through the inlet through the center. However, it is also possible to realize the input through an opening in the fitting.

[0049] The fiber suspension 1 passes radially outwards through the cooperating grinding surfaces and exits the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com