Honeycomb structure with crack resistance

A structure and honeycomb technology, applied in the direction of catalyst carrier, physical/chemical process catalyst, lighting and heating equipment, etc., can solve problems such as thermal shock and crack generation, and achieve the effect of inhibiting the generation and expansion of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

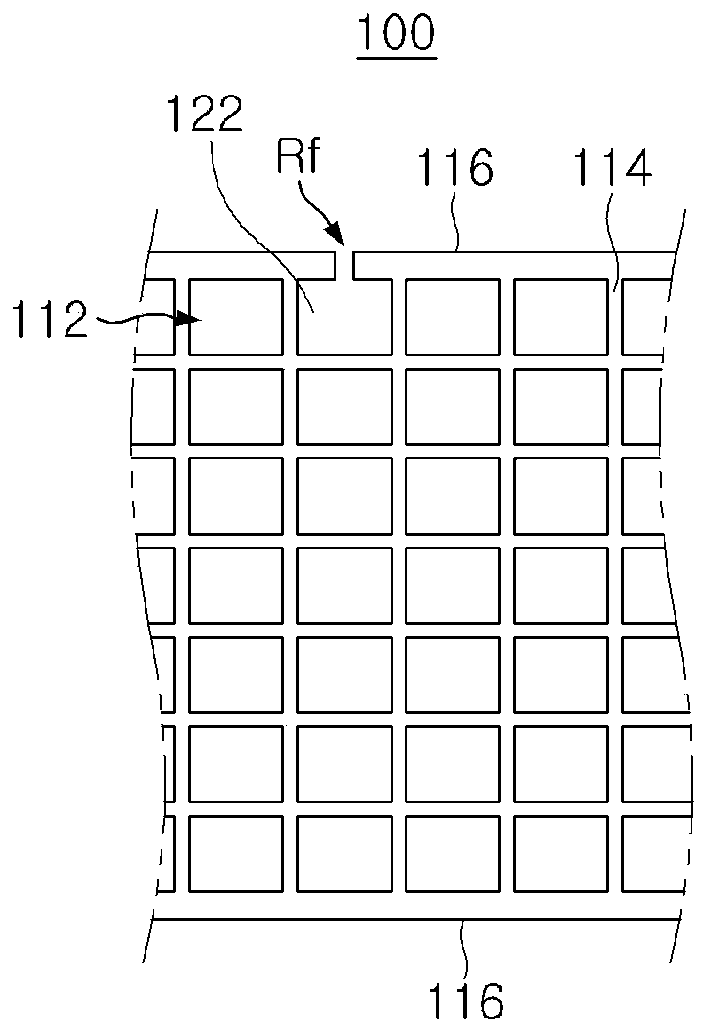

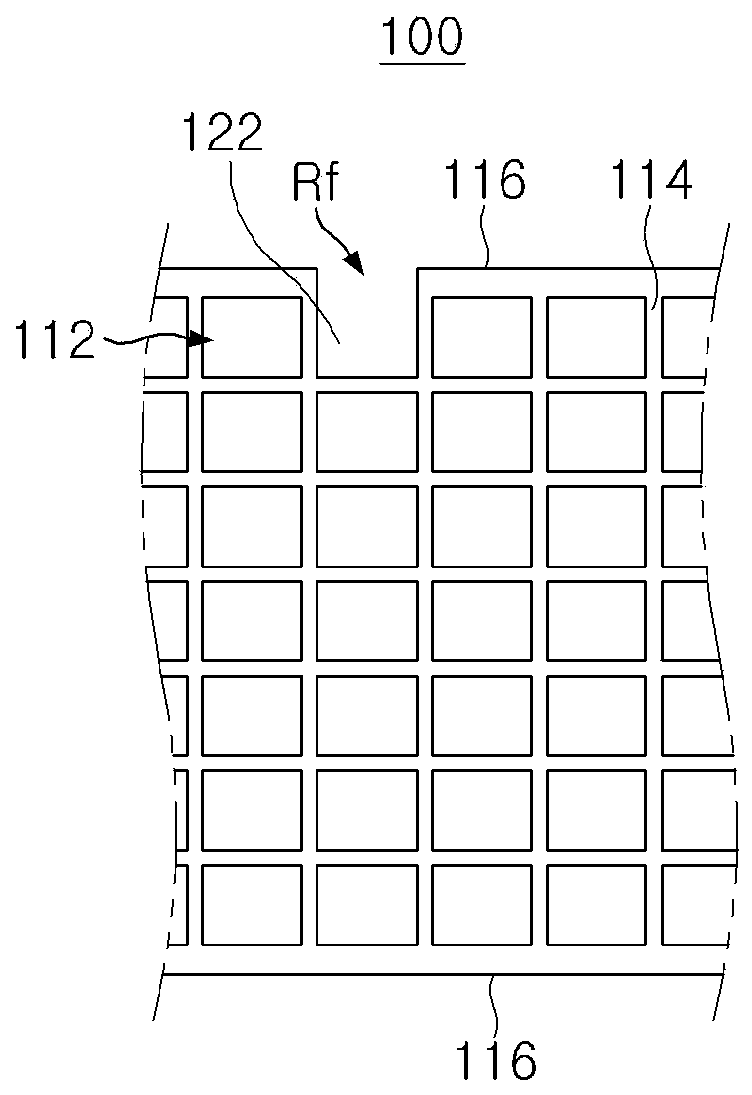

[0058] image 3 It is a figure which shows roughly the cross-sectional structure of the honeycomb structure of the 2nd Example of this invention.

[0059] image 3 The residual stress relaxation feature Rf of Rf is another realization form of the outer wall longitudinal section. In this embodiment, one chamber unit has no outer wall and is exposed to the outside. In this configuration, the residual stress relaxation features also still interrupt the continuity of the left and right outer walls of the cell unit.

[0060] image 3 The method of forming the outer wall longitudinal section by exposing one chamber unit is shown, but those of ordinary skill in the art to which the present invention pertains to who is exposed to the present invention can understand that two or more adjacent in a direction parallel to the outer wall surface may be formed. The chamber unit or two or more chamber units adjacent in the direction perpendicular to the outer wall surface are exposed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com