Disc brake, more particularly for commercial vehicles

A technology of disc brakes and brake discs, applied to disc brakes, can solve problems such as jamming and difficulties, and achieve the effects of reducing manufacturing costs, eliminating jamming, and significant mechanical advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

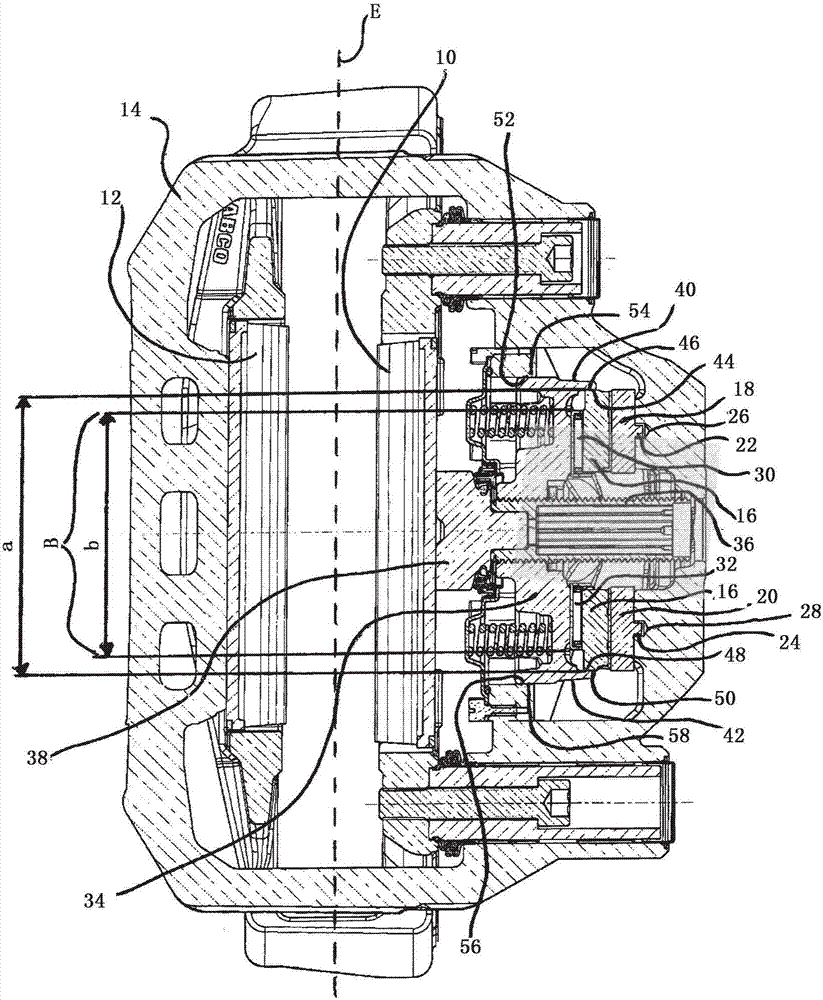

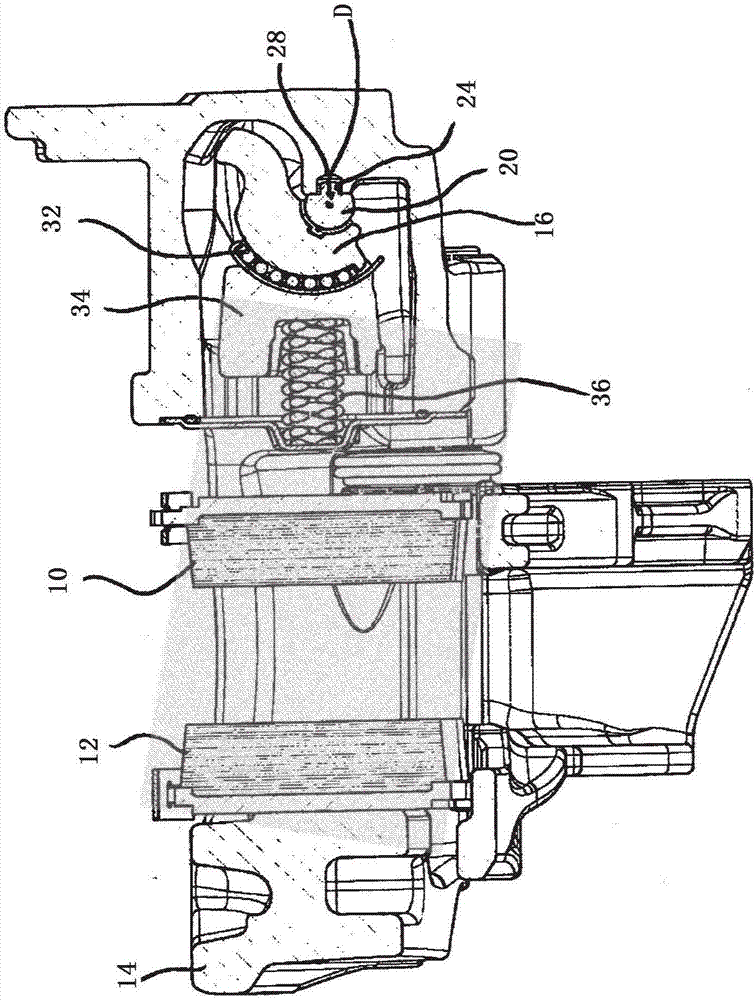

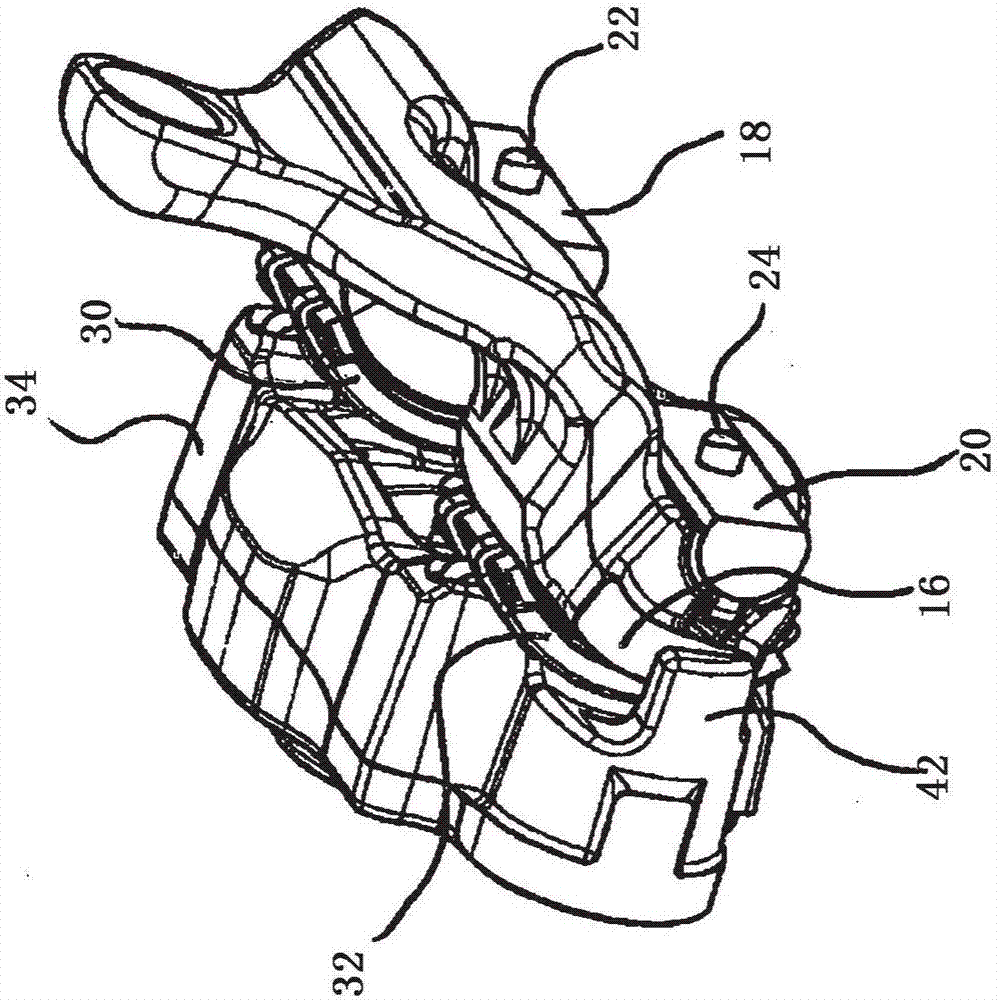

[0027] The pressure-side brake lining 10 and the rim-side brake lining 12 belong to the disk brake shown in the drawing and are located on opposite sides of the disk brake not shown in the drawing. superior. However, the main plane of the disc brake is drawn and provided with the reference E. Furthermore, the brake caliper 14 belongs to the disc brake, which is referred to as a sliding caliper. The brake shaft belonging to the hold-down device is designated with the reference numeral 16 . Its axis of rotation bears the reference D. On the side of the brake lining 10 facing away from the contact side, the brake shaft 16 is supported on the brake caliper 14 via sliding blocks 18 , 20 . The sliders each have a projection 22 , 24 which is inserted into a blind hole 26 or 28 .

[0028] On the side of the brake lining 10 facing the pressure side, the brake shaft 16 is supported on a pressure piece 34 via rotary bearings 30 , 32 . The pressure piece 34 is supported on the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com