Hoisting crane and offshore vessel

A technology for cranes and booms, which is applied to cranes, hoisting devices, transportation and packaging, etc., and can solve the problem of low lifting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

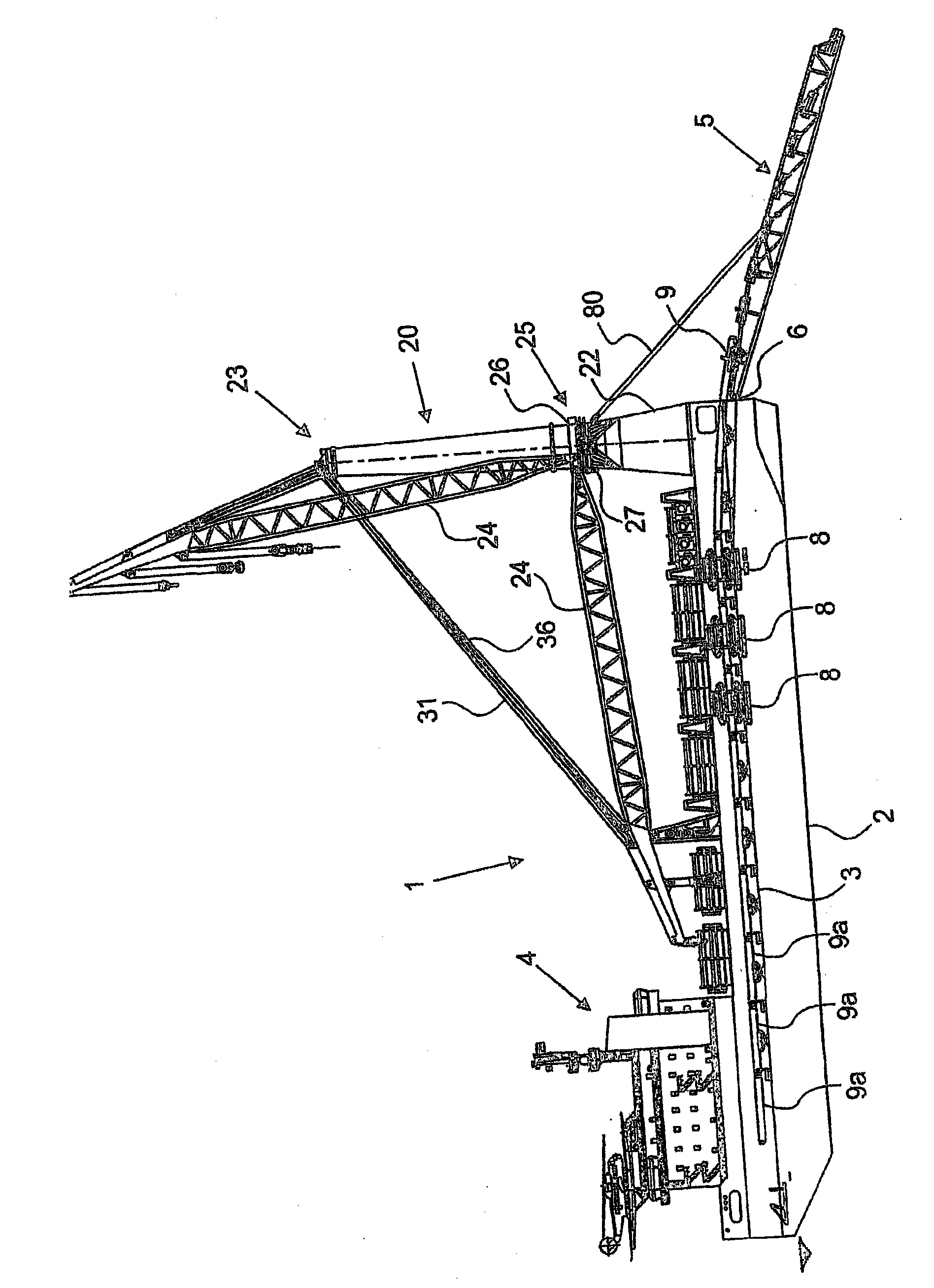

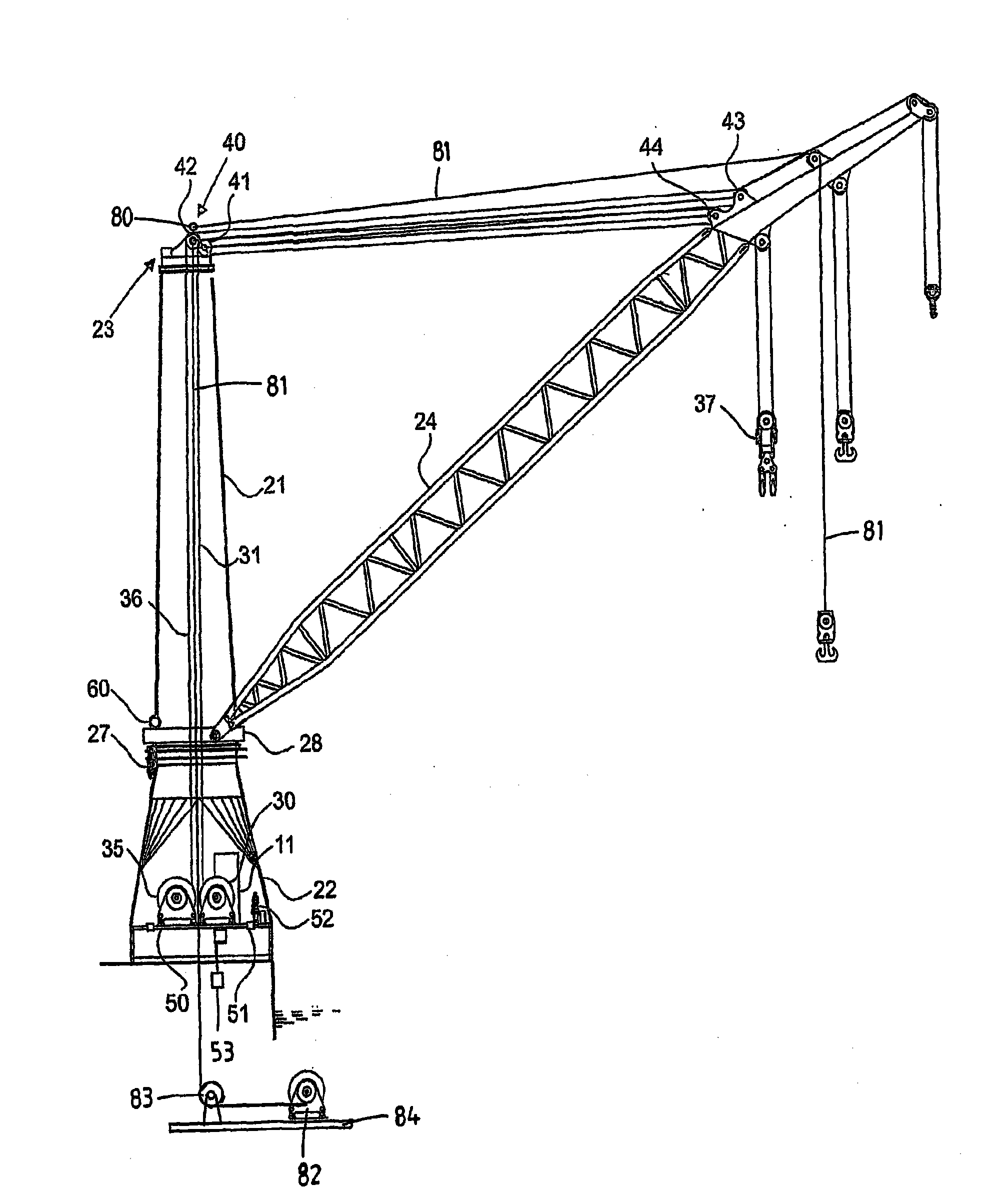

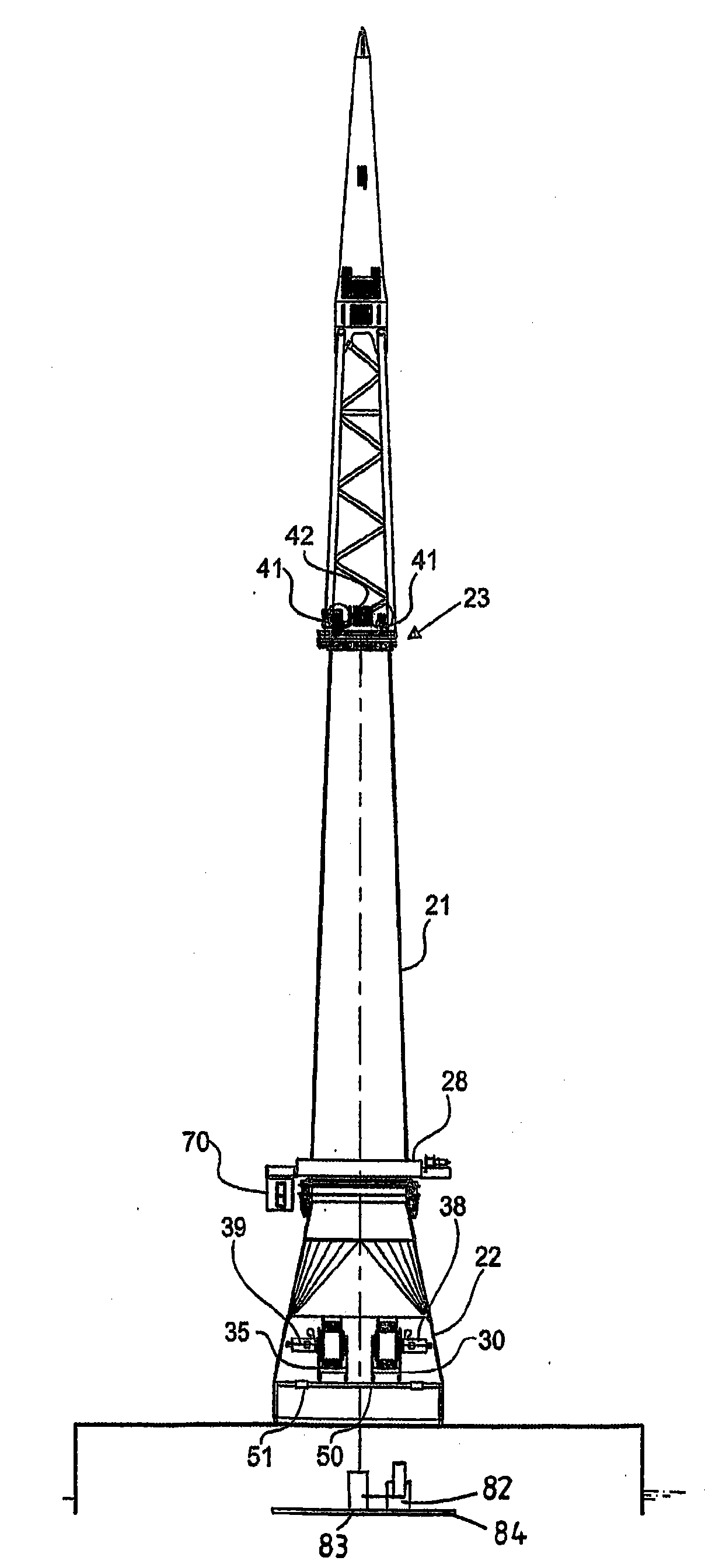

[0013] figure 1 A marine vessel 1 particularly suitable for laying pipelines on the seabed is shown. Obviously the vessel can be of different types, eg semi-submersible. The vessel may also be a platform, such as a tension leg platform or other platform.

[0014] The ship 1 includes a hull 2 and a working deck 3 , and at the front of the hull 2 is provided a superstructure 4 such as a crew accommodation.

[0015] Vessel 1 is provided with a pipeline-laying installation in an s-shaped arrangement with one or more welding stations on working deck 3 for joining together pipe sections 9a in a generally horizontal orientation . Also on the working deck 3 are so-called tensioners 8 for carrying the weight of the pipe 9 , which is suspended downwards from the vessel 1 .

[0016] In addition, the vessel 1 also has a stiger 5 protruding beyond the hull 2 of the vessel 1 at the rear side of the vessel 1, which engages with the hull 2 at a junction point on the hull 2 so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com