Single-longitudinal axial flow rigid-flexible coupling corn threshing device

A rigid-flexible coupling, corn threshing technology, used in threshing equipment, agriculture, applications, etc., can solve the problems of high grain impact force and rubbing strength, low grain breakage rate, corn grain damage, etc. The effect of improving the removal rate and reducing the strength of the action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

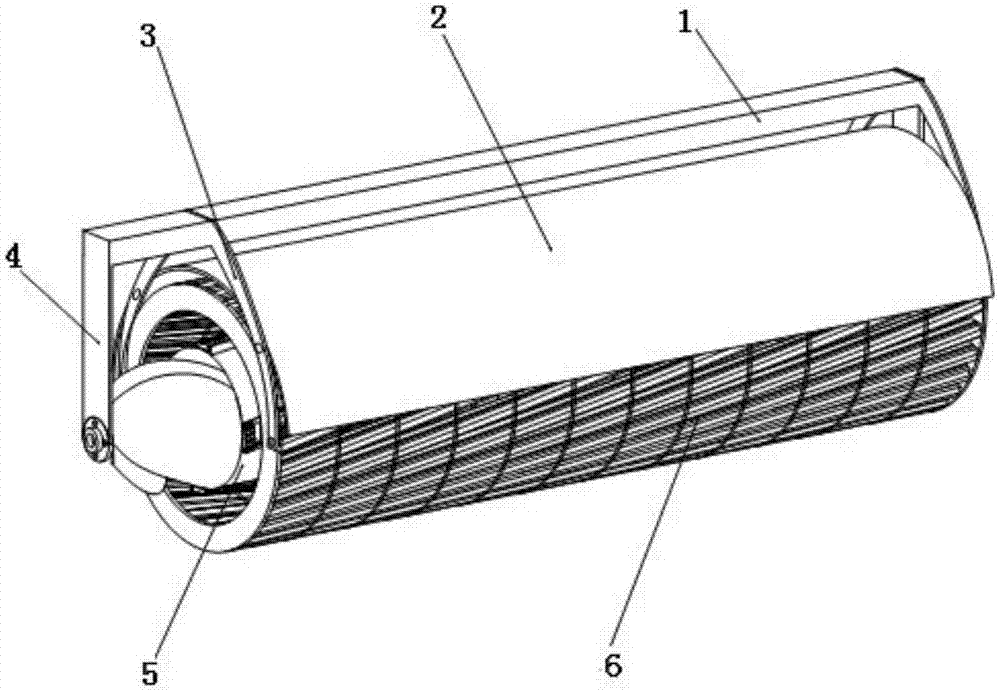

[0043] Such as figure 1 As shown, the single longitudinal axial flow rigid-flexible coupling corn threshing device of the present invention includes a frame 1 and a boom 4 extending in the same direction along the two ends of the beam of the frame 1; at least two arc-shaped crank arms 3, The middle part is fixed on the beam; the columnar threshing drum 5 is rotatably supported on the frame 1 at both ends, and is located at the extended end of the boom 4; the hollow cylindrical concave plate sieve 6 is coaxially set on the columnar threshing cylinder. The outside of the drum 5 is fixed inside the extended end of the curved arm 3, and the diameter of the concave screen 6 gradually increases from one end to the other.

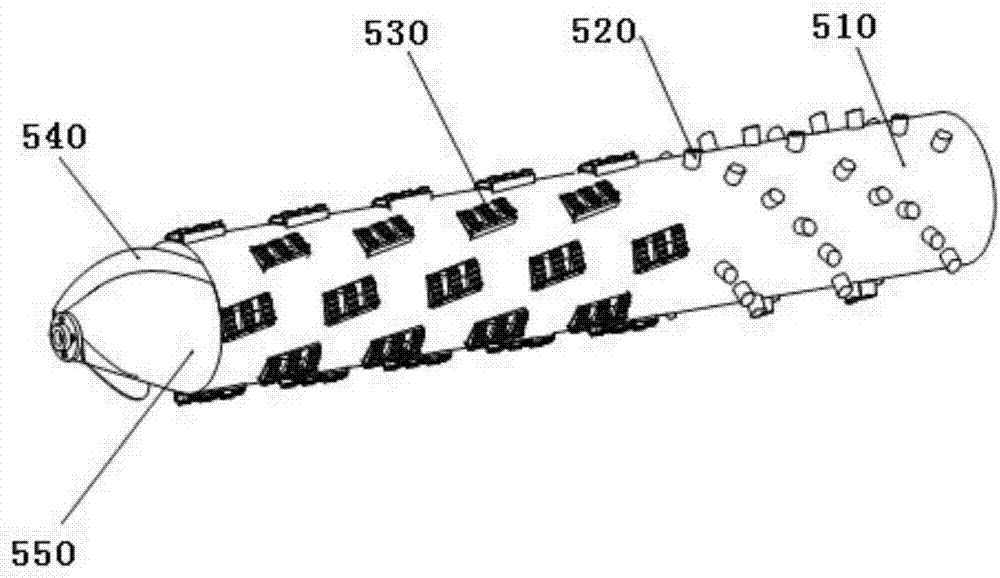

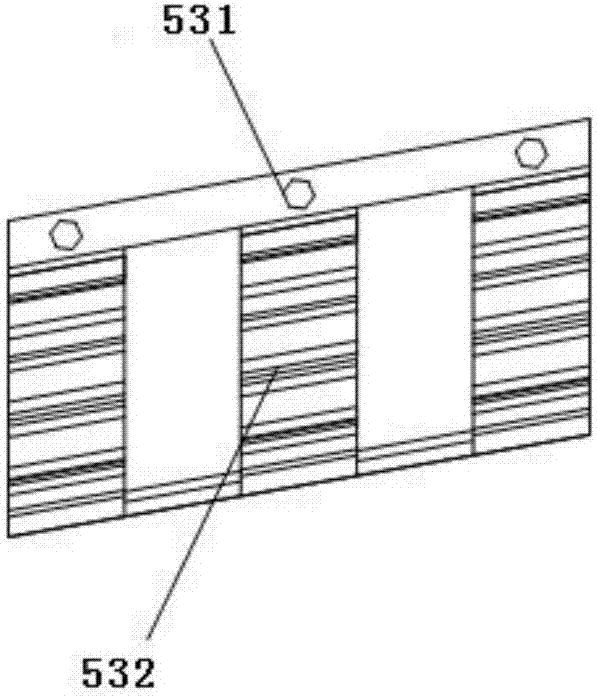

[0044] Such as figure 2 As shown, the outer surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com