A combined type reaction temperature control method and device for olefin polymerization

A technology of reaction temperature and olefin polymerization, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc. Problems such as temperature control operation of the external polymerization reactor to achieve the effect of increasing humidity, saving space and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

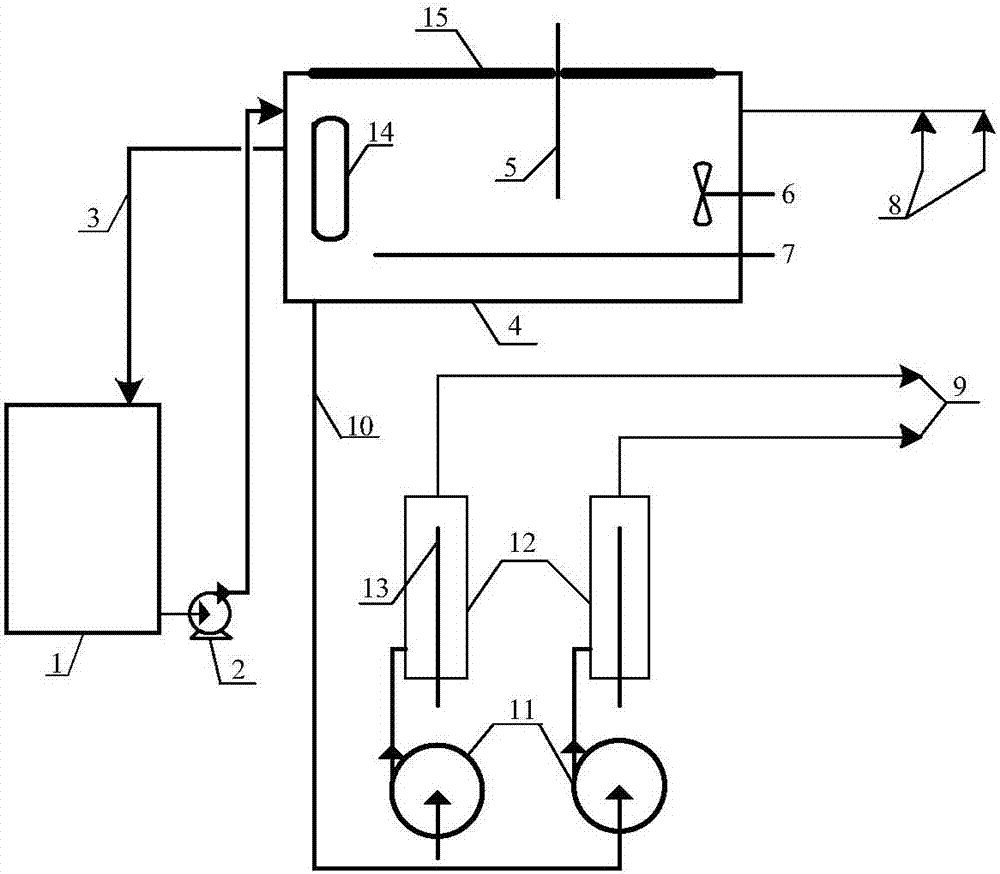

[0025] Start the agitator 6, set the temperature of the constant temperature tank 4 to be 70°C, and the heater 7 starts heating. When the temperature of the constant temperature tank 4 reaches the set temperature, the heater 7 automatically stops heating, and the polymerization reaction 1 and the polymerization reaction 2 start to react;

[0026] Temperature control one: one of the circulation pipes 9 controls the temperature of the first polymerization reaction, the power of the circulation pump 11 is set at 30%, and the DCS system calculates the heating power of the secondary heater 12 according to the requirements of the first temperature control of the polymerization reaction, and the heated circulation The water passes through the circulation pipe 9 to control the first polymerization reaction, and the heat-exchanged circulating water enters the constant temperature tank 4 through the return pipe 8;

[0027] Temperature control 2: Another circulation pipe 9 controls the te...

Embodiment 2

[0030] Polymerization reaction 1: temperature control 70°C

[0031] Polymerization two: temperature control 70 ℃

[0032] Start the agitator 6, set the temperature of the constant temperature tank 4 to be 70°C, and the heater 7 starts heating. When the temperature of the constant temperature tank 4 reaches the set temperature, the heater 7 automatically stops heating, and the polymerization reaction 1 and the polymerization reaction 2 start to react;

[0033] Temperature control one: one of the circulation pipes 9 controls the temperature of the polymerization reaction one, the power of the circulation pump 11 is set at 60%, the DCS system sets the secondary heater 12 to not start, and the circulating water passes through the circulation pipe 9 to carry out the polymerization reaction one Control, the heat-exchanged circulating water enters the constant temperature tank 4 through the return pipe 8;

[0034] Temperature control 2: Another circulation pipe 9 controls the temper...

Embodiment 3

[0037] Polymerization reaction 1: temperature control 85°C

[0038] Polymerization two: temperature control 70 ℃

[0039] Start the agitator 6, set the temperature of the constant temperature tank 4 to be 70°C, and the heater 7 starts heating. When the temperature of the constant temperature tank 4 reaches the set temperature, the heater 7 automatically stops heating, and the polymerization reaction 1 and the polymerization reaction 2 start to react;

[0040] Temperature control one: one of the circulation pipes 9 controls the temperature of the first polymerization reaction, the power of the circulation pump 11 is set at 30%, and the DCS system calculates the heating power of the secondary heater 12 according to the requirements of the first temperature control of the polymerization reaction, and the heated circulation The water controls the polymerization reaction 1 through the circulation pipe 9, and the heat-exchanged circulating water enters the constant temperature tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com