A method of calibrating the guide plate at the entrance side of the hot strip finishing mill

A finishing mill and entry-side technology, which is applied in the field of calibrating the entry-side guide plate of a hot continuous strip finishing mill, can solve problems such as the inability of alignment to meet the standard, and achieves reduction of deviation accidents, reduction of rolling accidents, and improvement of the finished product rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

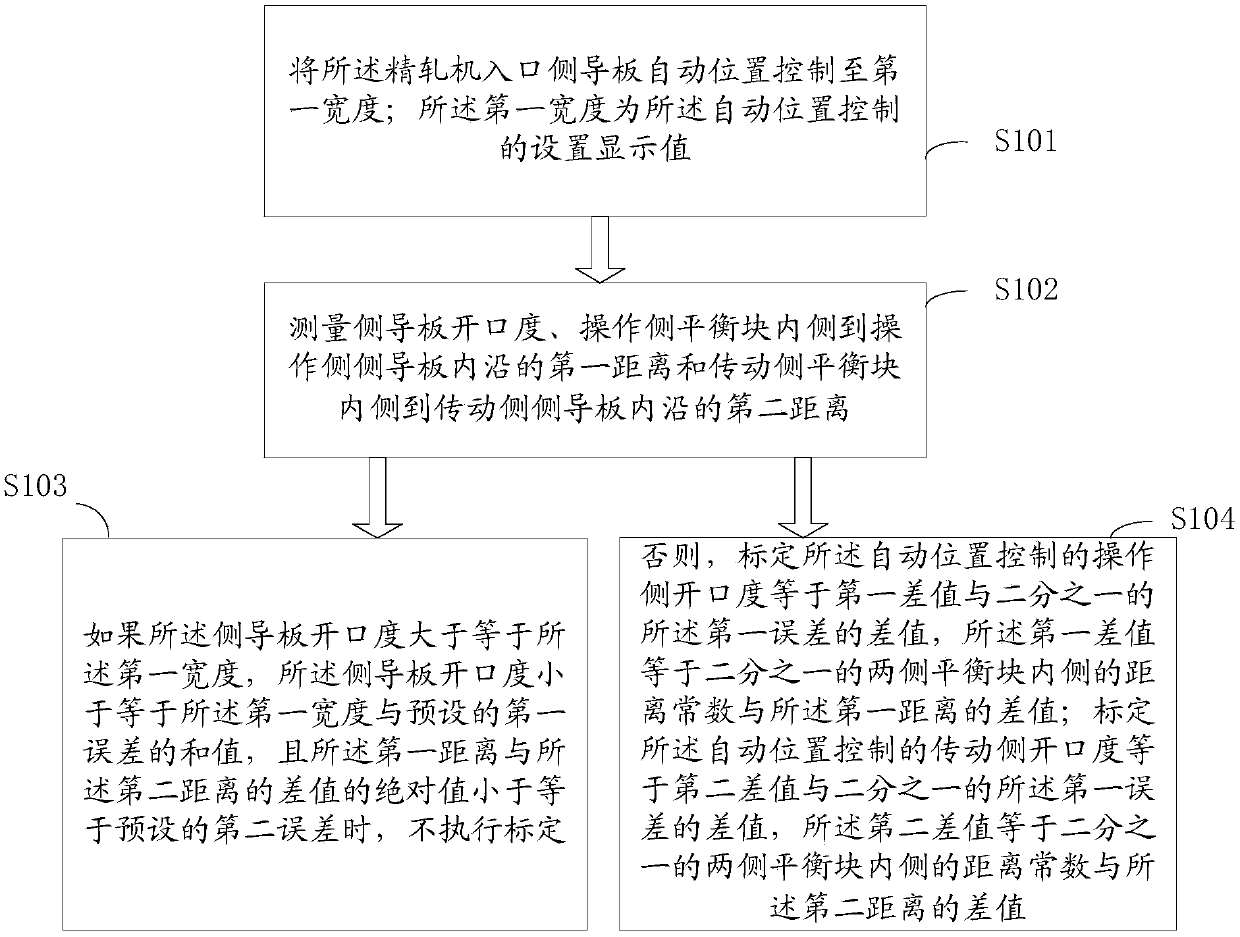

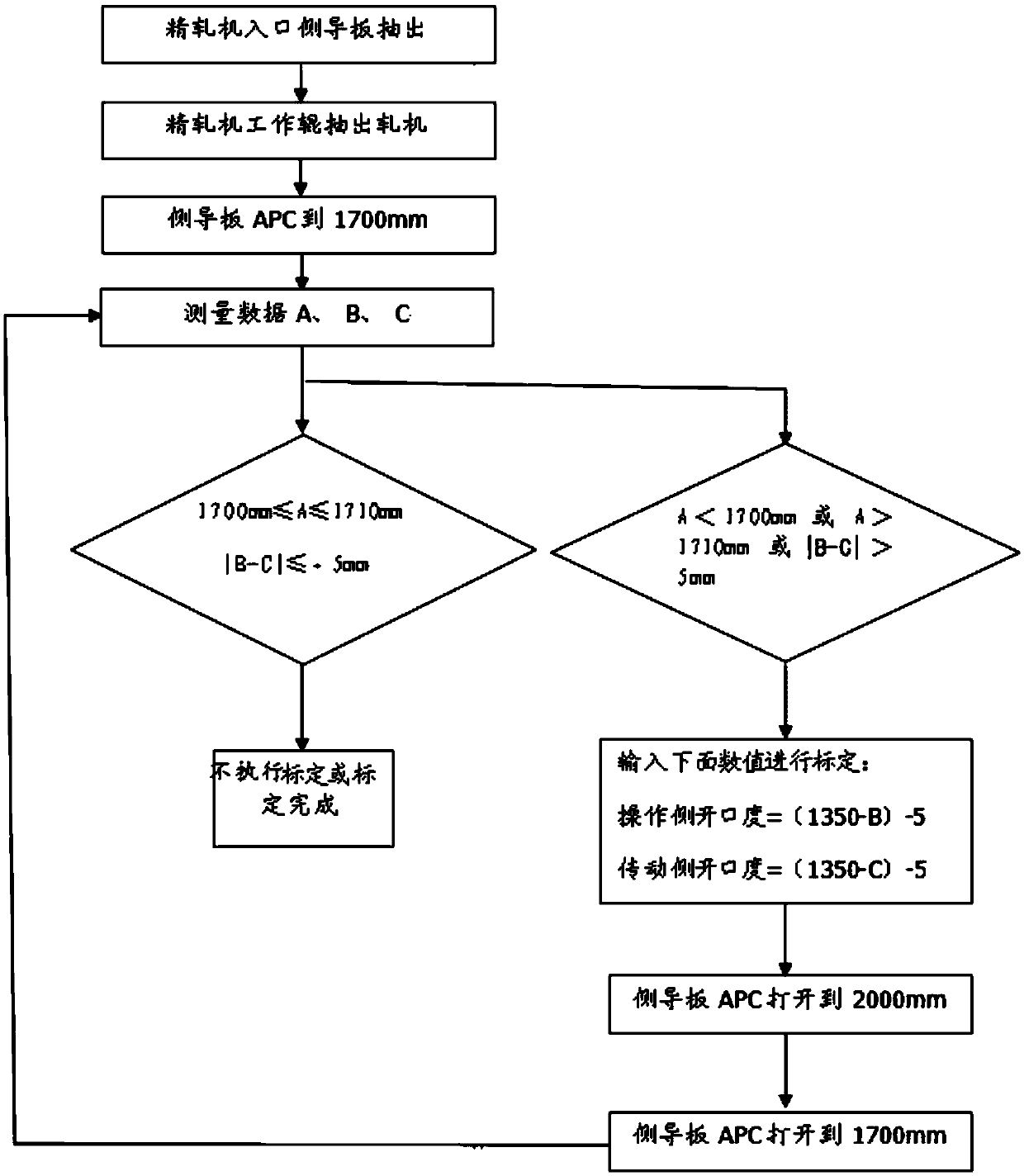

[0073] Pull out the guide plate on the entrance side of the rolling mill first, and pull out the work roll of the finishing mill from the rolling mill;

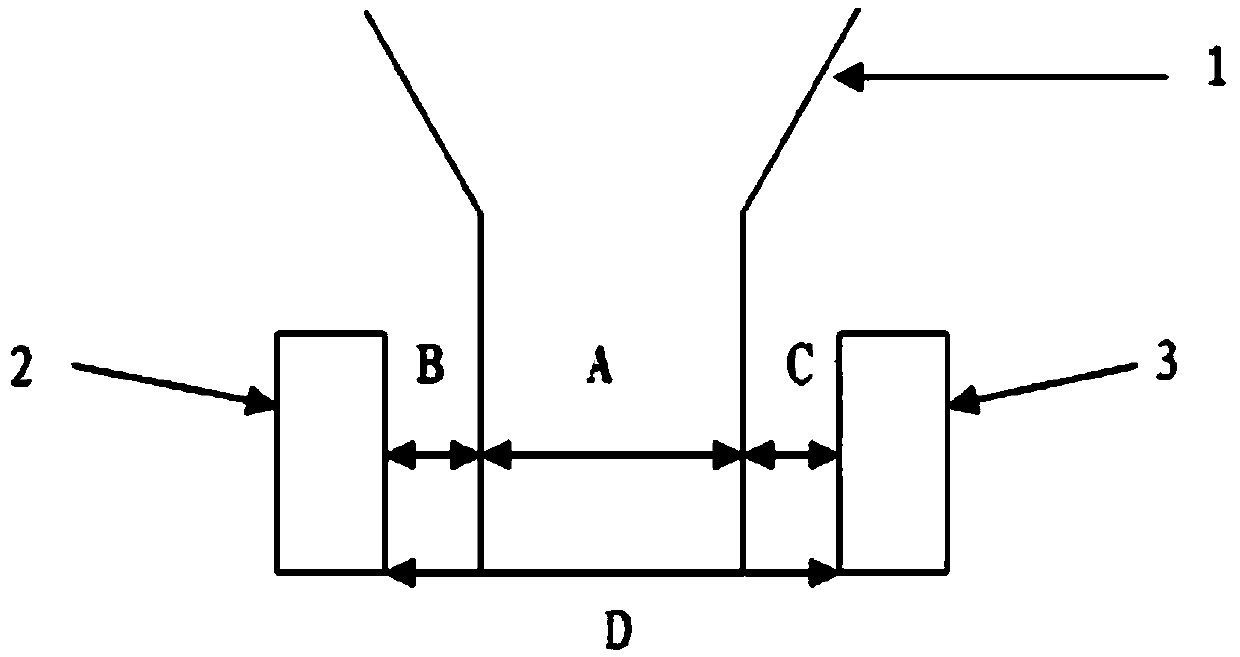

[0074] Then adjust the APC of the side guide plate at the entrance of the rolling mill to 1700mm, and measure the data A=1715mm, B=490m, C=495mm; since A>1710mm, the opening degree of the side guide plate does not meet the standard, and the alignment |B-C|=5mm≤5mm, then The alignment meets the standard, and the side guides need to be calibrated;

[0075] The input calibration value is: operation side opening = (1350-490)-5 = 855mm, transmission side opening = (1350-495)-5 = 850mm, and the opening on both sides of the side guide plate is calibrated;

[0076] Then, APC the entrance side guide plate of the finishing mill to 2000mm, and then APC the side guide plate to 1700mm.

[0077] Measurement data A=1710mm, B=495mm, C=495mm. The opening and centering of the side guides meet the standards. The side guides have been calibra...

example 2

[0080] Pull out the guide plate on the entrance side of the finishing mill first, and pull out the work roll of the finishing mill from the rolling mill;

[0081] Then APC the entrance side guide plate of the finishing mill to 1700mm, the measurement data A=1710mm, B=485mm, C=505mm; when 1700mm≤A≤1710mm, the opening degree of the side guide plate meets the standard, and the degree of alignment |B-C|=20mm>5mm , then the middle level does not meet the standard, and the side guide plate needs to be calibrated;

[0082] The input calibration value is: operation side opening = (1350-485)-5 = 860mm, transmission side opening = (1350-505)-5 = 840mm, and the opening on both sides of the side guide plate is calibrated.

[0083] Adjust the APC of the entrance side guide plate of the finishing mill to 2000mm, and then adjust the APC of the side guide plate to 1700mm.

[0084]Measurement data A=1710mm, B=495mm, C=495mm. The opening and centering of the side guides meet the standards. T...

example 3

[0087] Pull out the guide plate on the entrance side of the finishing mill first, and pull out the work roll of the finishing mill from the rolling mill;

[0088] Then adjust the APC of the entrance side guide plate of the finishing mill to 1700mm, and measure the data A=1690mm, B=495mm, C=515mm; when A5mm, the alignment does not meet the standard, and the side guide plate needs to be calibrated;

[0089] The input calibration value is: operation side opening = (1350-495)-5 = 850mm, transmission side opening = (1350-515)-5 = 830mm, and the opening on both sides of the side guide plate is calibrated;

[0090] Adjust the APC of the entrance side guide plate of the finishing mill to 2000mm, and then adjust the APC of the side guide plate to 1700mm.

[0091] Measurement data A=1710mm, B=495mm, C=495mm. The opening and centering of the side guides meet the standards. The side guides have been calibrated successfully.

[0092] After the calibration of Example 3, the opening and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com