Mixture proportion design method for cold regeneration of foamed asphalt with internal friction angle and cohesive force

A technology of cold recycled mixture and foamed asphalt, applied in the direction of analytical materials, instruments, measuring devices, etc., can solve problems such as water damage and achieve good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, the present invention will be further clarified with reference to the accompanying drawings and specific embodiments. It should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. After reading the present invention, those skilled in the art will understand various aspects of the invention. Modifications of the price form fall within the scope defined by the appended claims of this application.

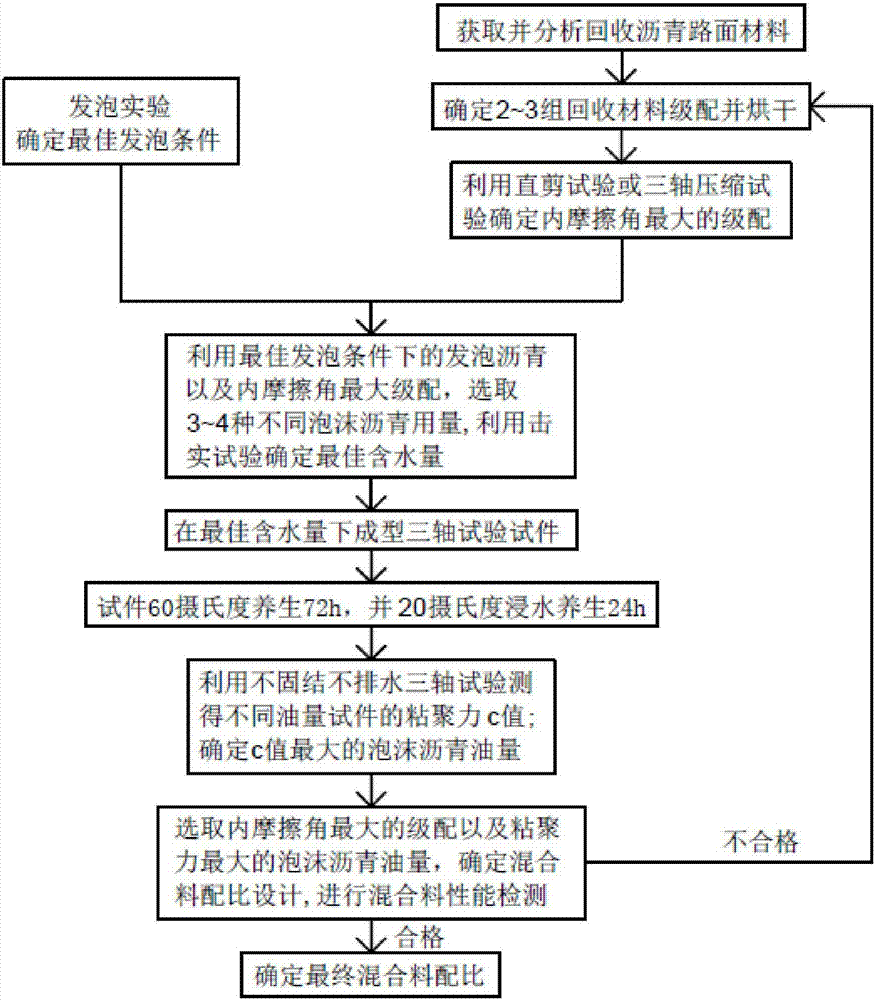

[0020] The design method of foamed asphalt cold recycled mixture ratio design method of internal friction angle and cohesive force, including determining the best gradation of recycled materials based on the internal friction angle measured by direct shear test or triaxial compression test; determining the best foaming condition of asphalt Then select 3 to 4 different foamed asphalt dosages, use compaction test to determine the optimal moisture content; shape and immerse the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com