An integrated monocrystalline silicon growth furnace electrode lifting mechanism

A technology of electrode lifting and single crystal silicon, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of unbalanced thermal field, affecting the quality of crystal growth and production crystal rods, etc., and achieve thermal field temperature balance, Facilitate crystal growth and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

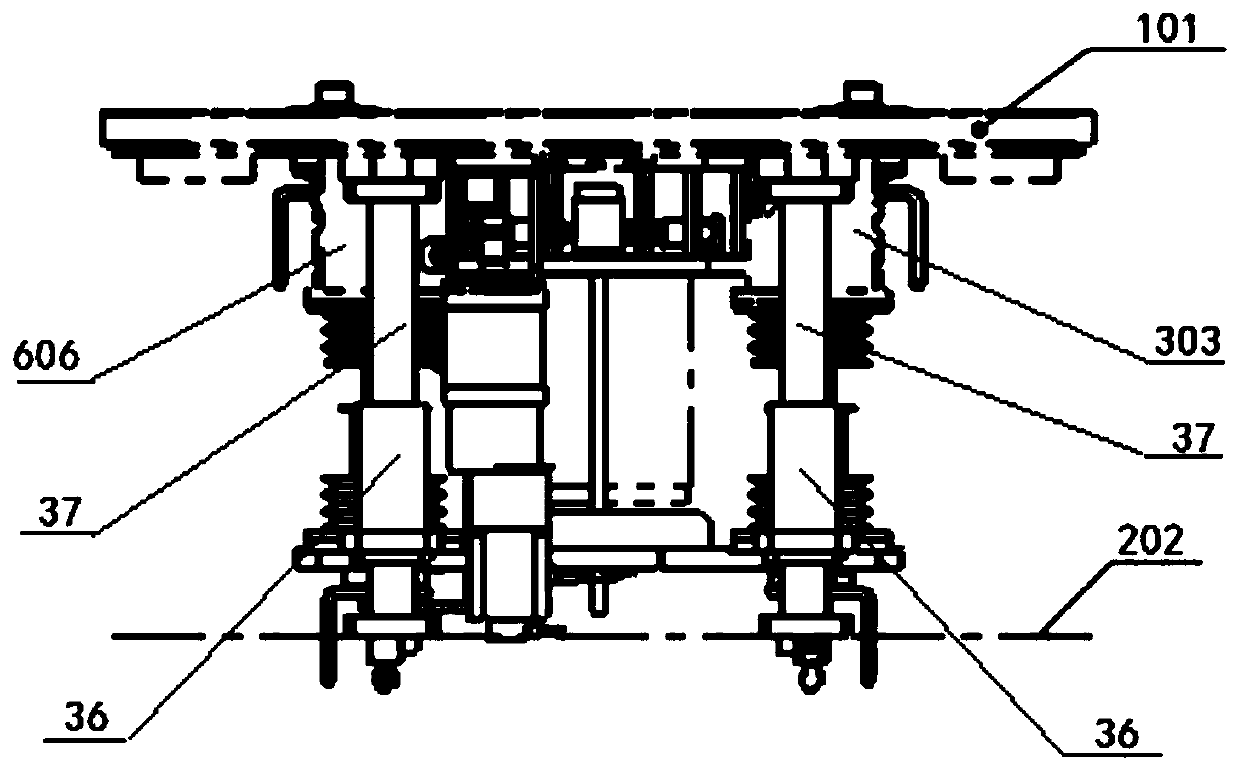

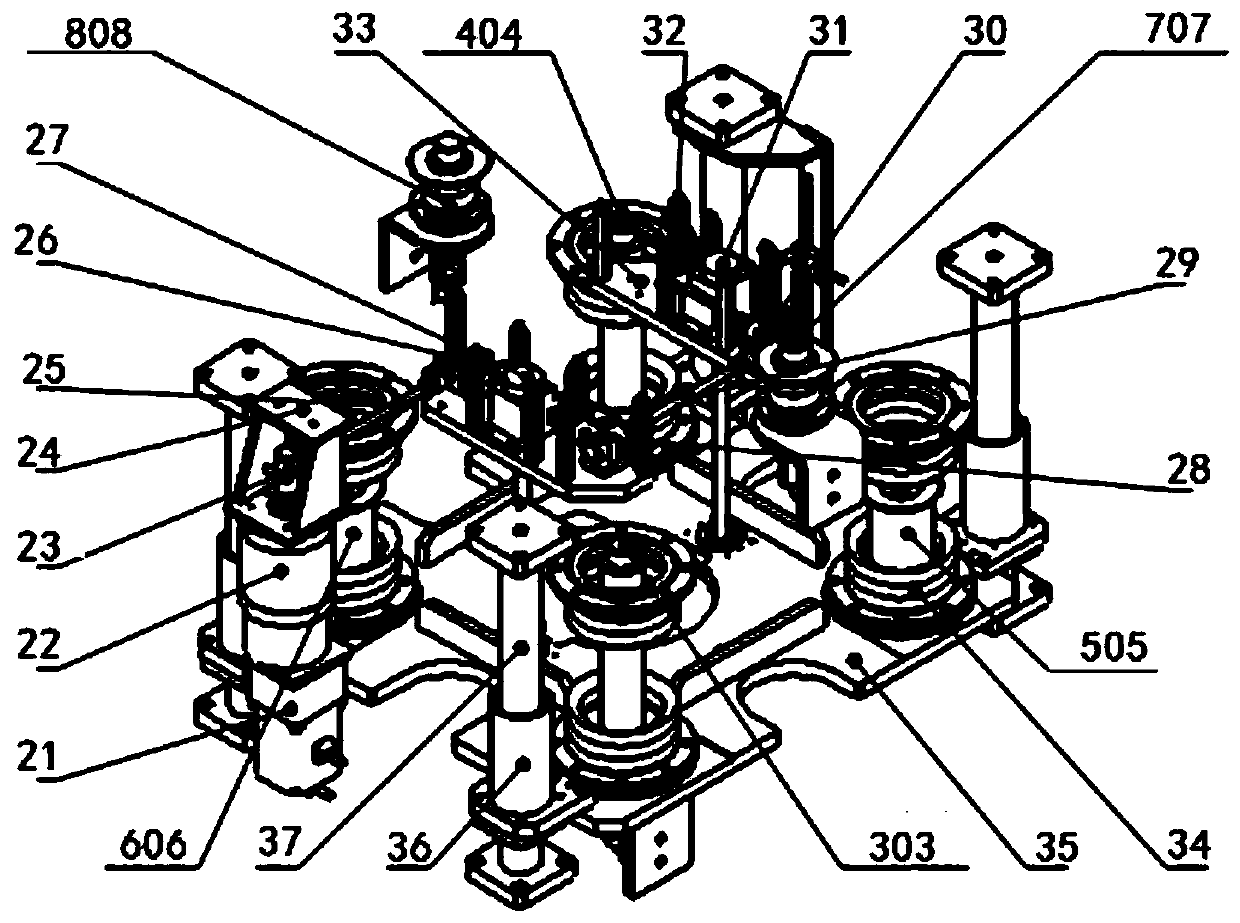

[0029] like figure 1 , 2 The one-piece monocrystalline silicon growth furnace electrode lifting mechanism shown includes four guide pillars 37 fixedly installed between the single crystal furnace chassis 101 and the frame 202, and four guide pillars arranged on the four guide pillars and can move along the guide The base plate 35 that the column moves up and down, the four guide columns 37 are distributed at the four corners of the base plate 35 in four diagonal directions of the left front side, the right front side, the right rear side, and the left rear side. Linear bearings 36 are respectively installed on the four corners of 35, and each linear bearing 36 is slidably connected with respective corresponding guide posts 37;

[0030] The first main electrode 303 and the second main electrode 404 are respectively provided on the left front side and the right rear side of the substrate 35, and the first auxiliary support 505 and the second auxiliary support are respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com