Three-dimensional coiled iron core type oil immersed transformer

A technology of oil-immersed transformers and three-dimensional wound iron cores, which is applied in the field of transformer manufacturing and can solve problems such as complexity, difficulty in winding winding, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

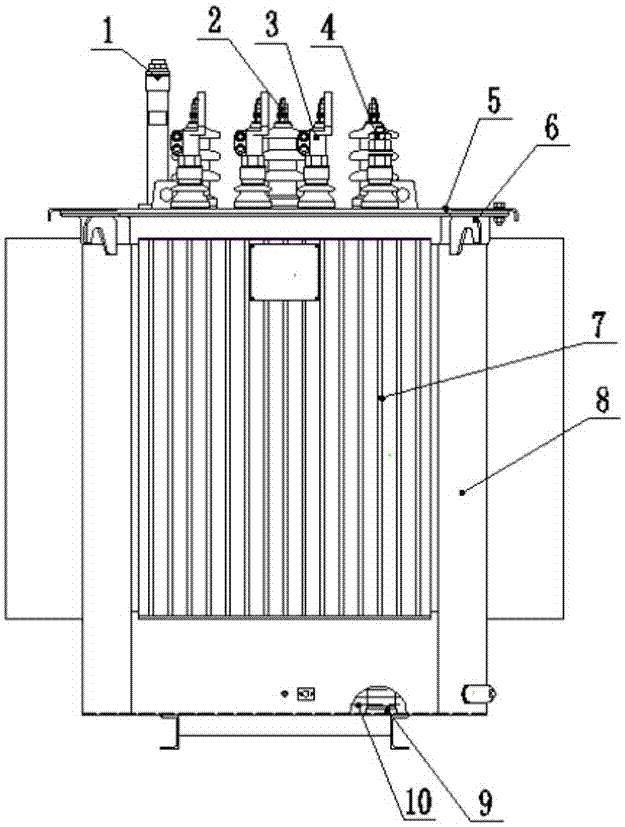

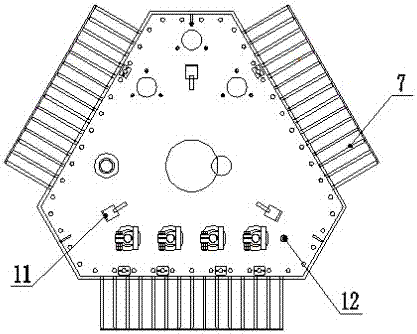

[0012] Such as figure 1 and figure 2 As shown, the three-dimensional wound iron core type oil-immersed transformer includes an oil tank 8, and the bottom of the oil tank 8 is provided with feet, and the feet are welded by "I"-shaped channel steel. Bolt holes are provided on the side of the feet corresponding to the oil tank. When the transformer is installed, the transformer can be installed and fixed through the bolt holes and bolts on the feet, so that the transformer is more stable and reliable in operation. The oil tank 8 is covered with a case cover 5, and the connection between the case cover 5 and the fuel tank is provided with a sealing ring. The lower end of the oil tank 8 is respectively provided with a grounding bolt, an oil sample valve, and a valve, and taking an oil sample from the oil sample valve can detect whether the transformer is working normally. The box cover 5 is provided with a side hanging plate 6, an upper hanging plate 11, a low-voltage bushing 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com