Preparation method and application of nanometer silicon carbide material with high metal content

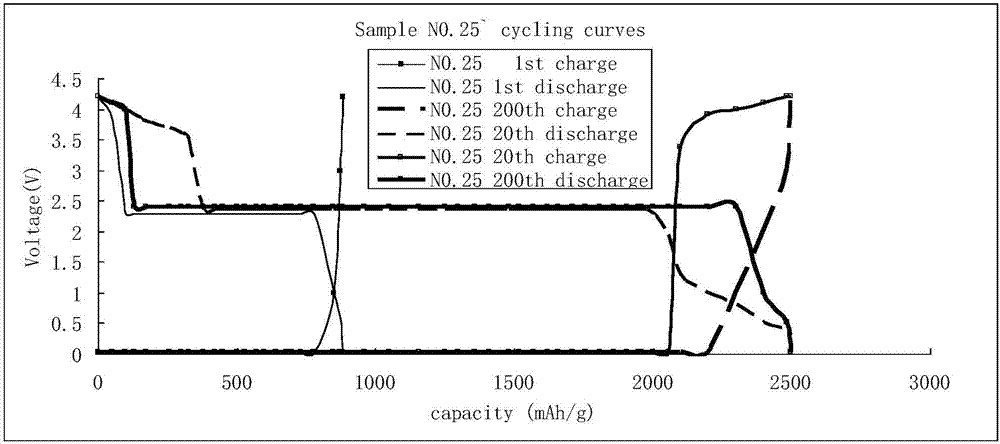

A nano-silicon carbide, high-metal technology, applied in the fields of silicon carbide, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the difficulty of doping silicon carbide, the complex metal doping process, and the unsatisfactory effect. and other problems, to achieve the effects of stable cycle performance, high energy density and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

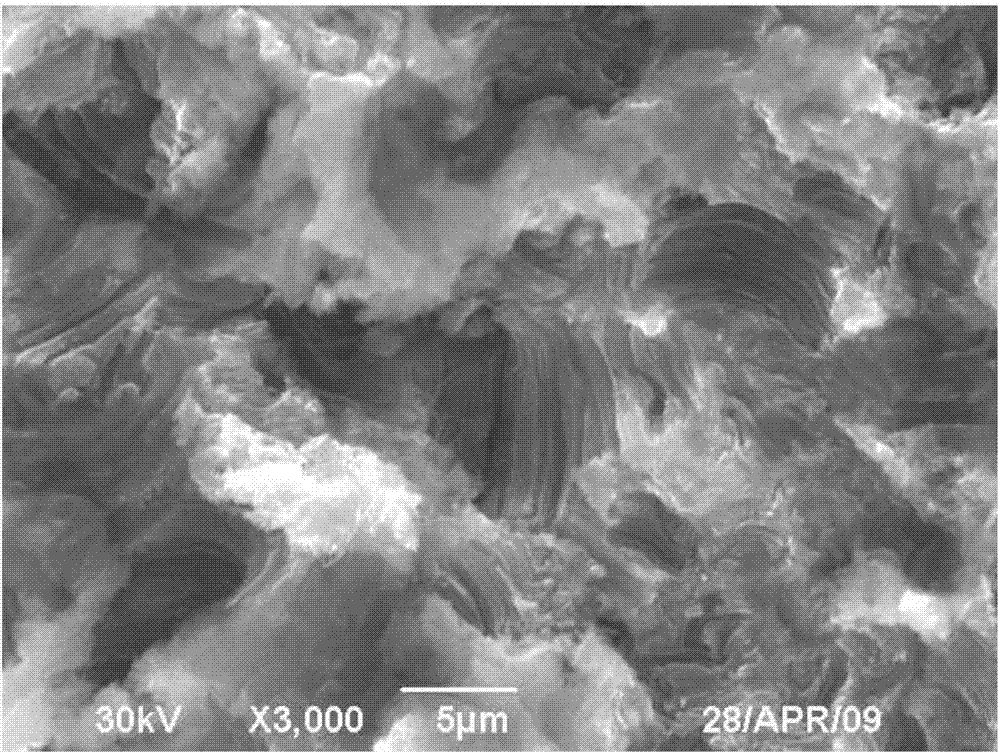

[0039] The specific preparation method of the nano-silicon carbide material with high metal content comprises the following steps:

[0040] (1) Preparation of mixed powder: in an inert atmosphere, weigh the lithium metal powder, neodymium metal powder and lanthanum metal powder whose surface has been nitrided by weight ratio of 60-80%: 10-20%: 10-20% , the average diameter of the powder particles is 0.4-5um. The lithium rare earth alloy powder, the silicon powder and the graphene powder are weighed in a weight ratio of 10-20%: 30-40%: 40-50%, 280g in total. The inert gas can be N 2 , Kr, He and other commonly used inert gases;

[0041] (2) Take amorphous silicon carbide powder, polysiloxane, lithiated polyacetylene, and mixed powder by weight ratio of 0.1-2%: 45-54.5%: 30-45%: 0.4-23%; the powder particles The average diameter is 0.5 ~ 5um;

[0042] (3) Put the material obtained in step (2) into a mechanical stirrer and add 200ml of acetone, seal and stir for 24 hours, mix...

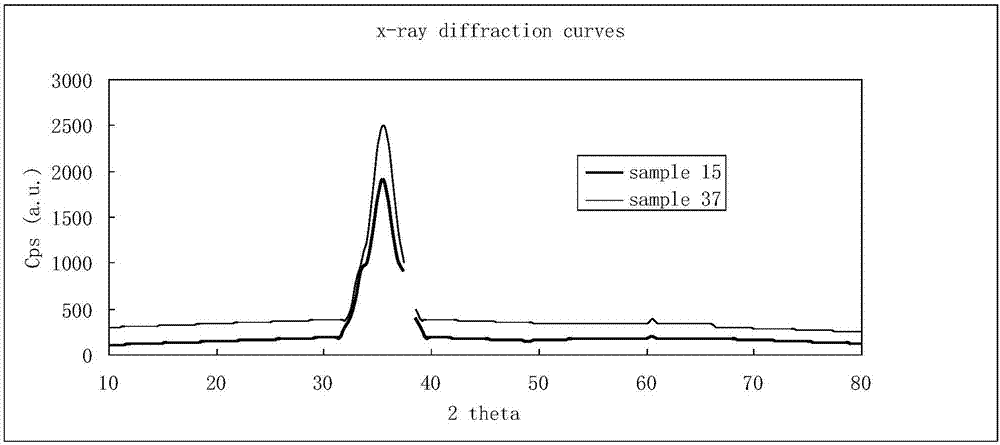

Embodiment 1

[0051] The raw materials used and their weight ratios are: 0.1% of amorphous silicon carbide powder, 54.5% of polysiloxane, 45% of lithium polyacetylene and 0.4% of mixed powder, wherein, in the mixed powder, lithium rare earth alloy powder, silicon powder and The weight ratio of graphene powder is 10%: 40%: 50%, and the weight ratio of metal lithium powder, metal neodymium powder and metal lanthanum powder in the described lithium rare earth alloy powder is: 60%: 20%: 20%, so The preparation method of the nano-silicon carbide material with high metal content is the same as above.

Embodiment 2

[0053] The raw materials used and their weight ratios are: 0.5% of amorphous silicon carbide powder, 51% of polysiloxane, 40% of lithiated polyacetylene and 8.5% of mixed powder, wherein, in the mixed powder, lithium rare earth alloy powder, silicon powder and The weight ratio of graphene powder is 20%: 30%: 50%, and the weight ratio of metal lithium powder, metal neodymium powder and metal lanthanum powder in the described lithium rare earth alloy powder is: 80%: 10%: 10%, so The preparation method of the nano-silicon carbide material with high metal content is the same as above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap