Storage battery electrode plate packaging machine

A technology of plate-cladding machine and storage battery, which is applied in secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc. Highly flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

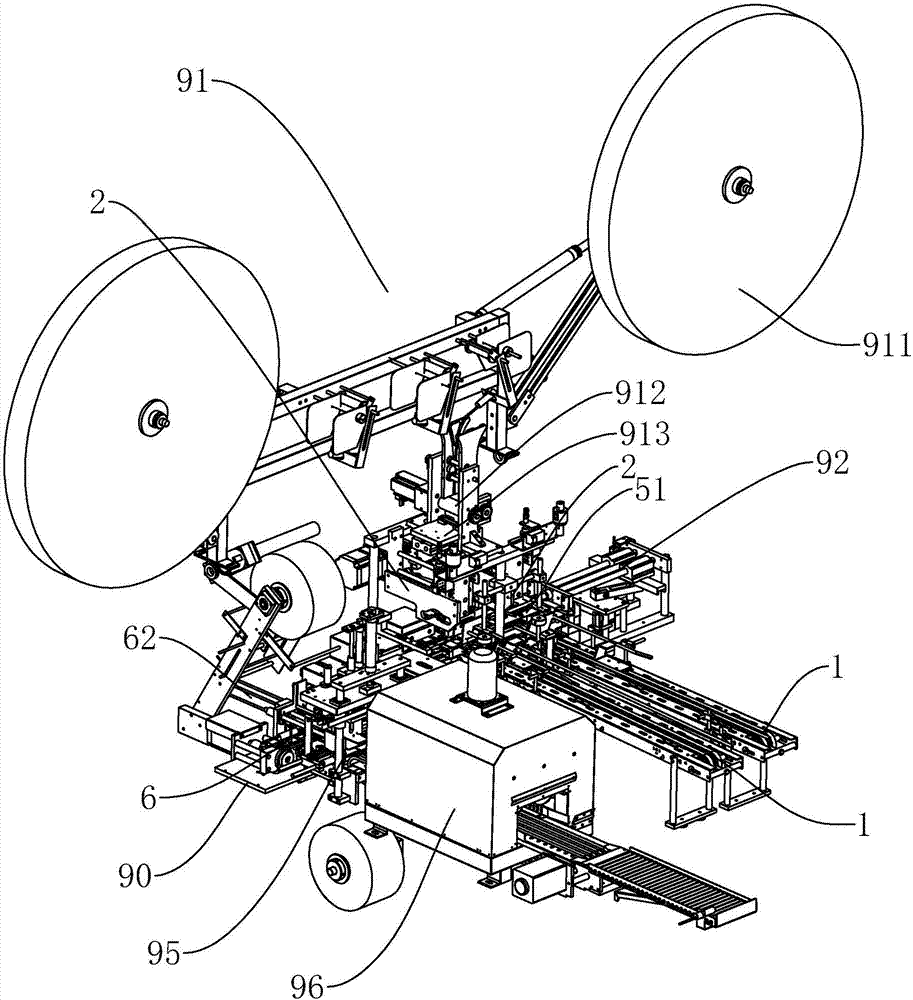

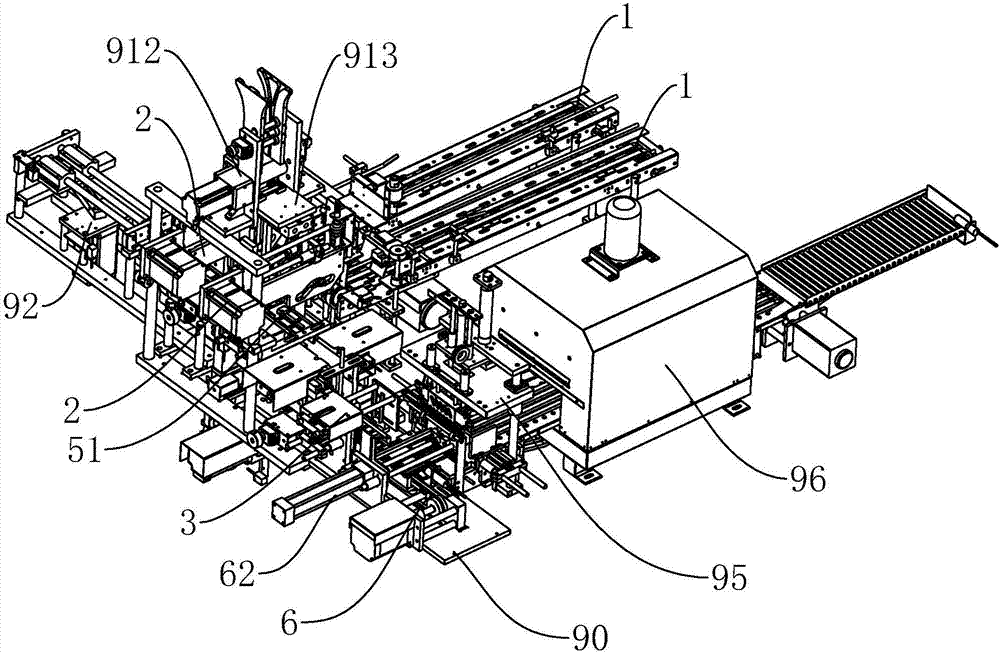

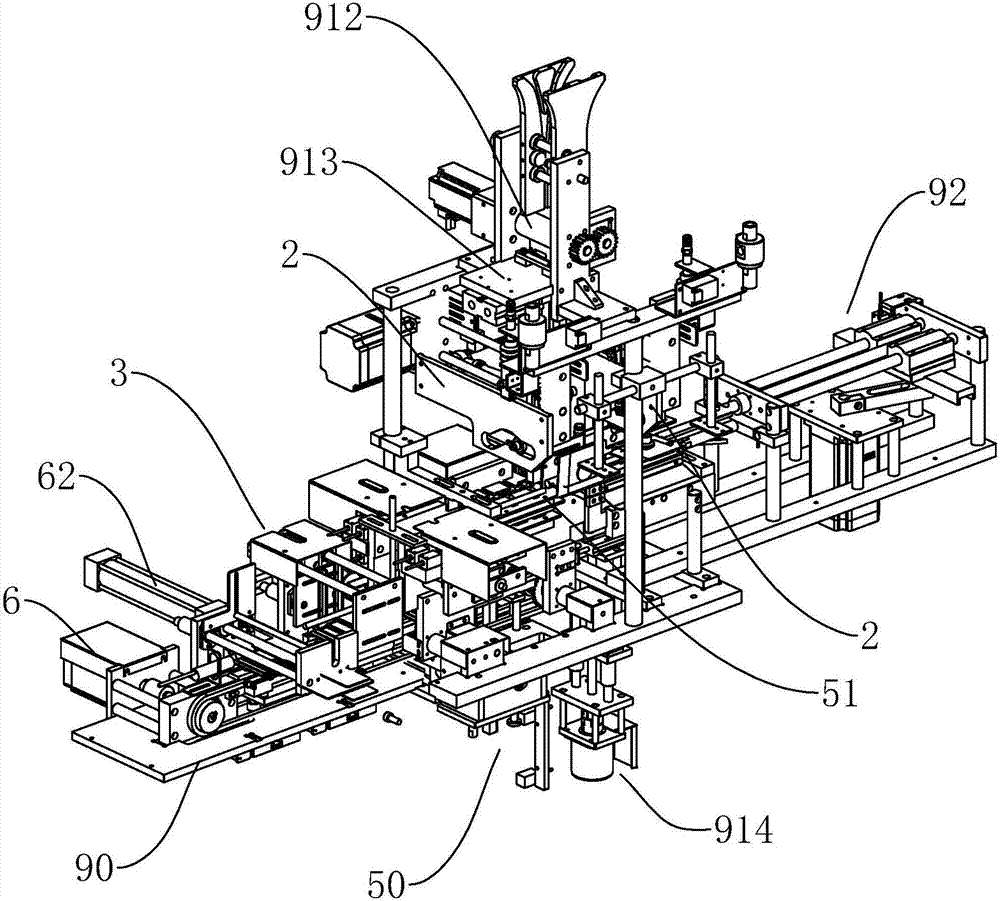

[0054] refer to Figure 1 to Figure 30 , Figure 1 to Figure 30 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, the battery wrapping machine includes: a frame 90 , a plate stacking mechanism, a plate feeding mechanism, a plate pushing mechanism 92 , and an output channel device 6 .

[0055] refer to Figure 6 to Figure 9 The stacking mechanism is arranged on the frame 90, which includes a stacking channel 51, a loading bin device, and a sinking device 50, and the stacking channel 51 is provided with a first blanking position 5a and a second blanking position 5b , between the first blanking position 5a and the second blanking position 5b, a wrapping paper channel 54 is arranged, the carrying bin device is arranged below the second blanking position 5b, and the sinking device 50 is arranged in the carrying bin Below the device, and the first blanking position 5a is connected to the loading bin device.

[0056] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com