Fixing tool for turbine blade machining

A technology for fixing tooling and turbine blades, used in workpiece clamping devices, manufacturing tools, etc., can solve the problems of unsatisfactory fixing effect of turbine blades, unstable processing quality, and failure to meet design requirements, and improve work and economic efficiency. , good consistency and stable processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

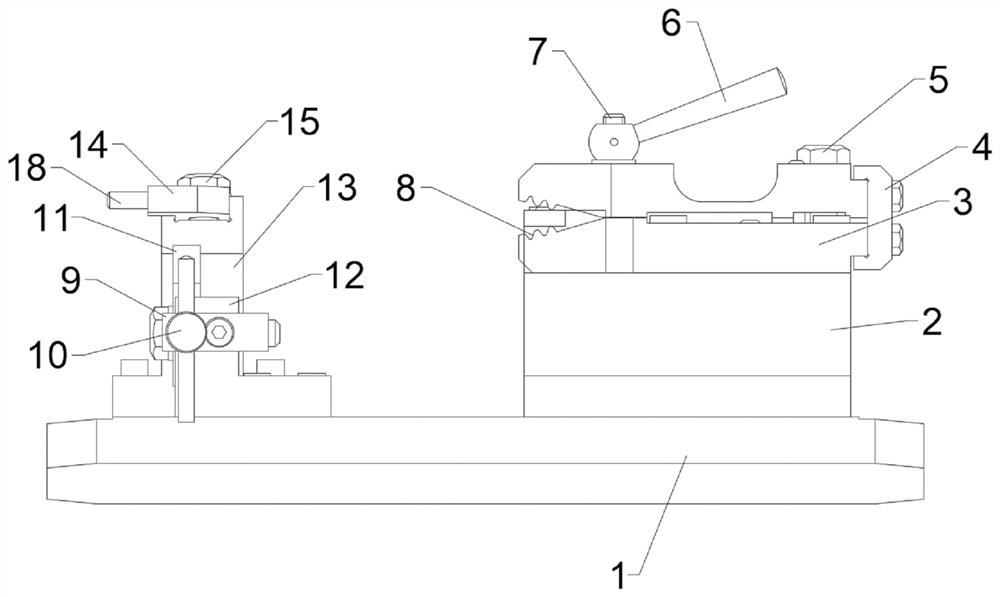

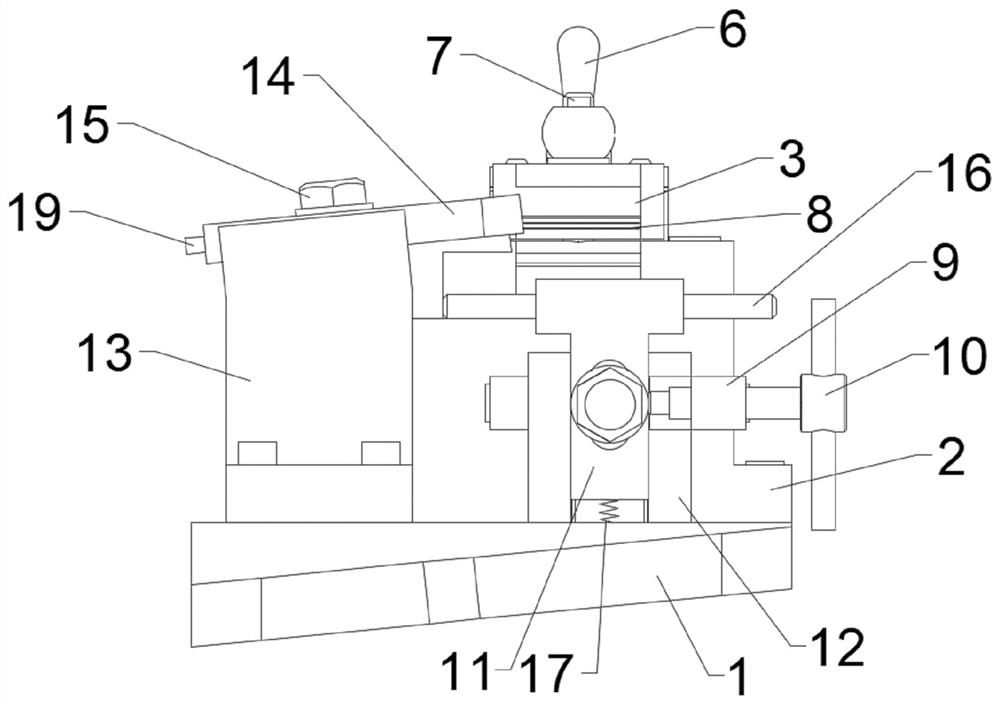

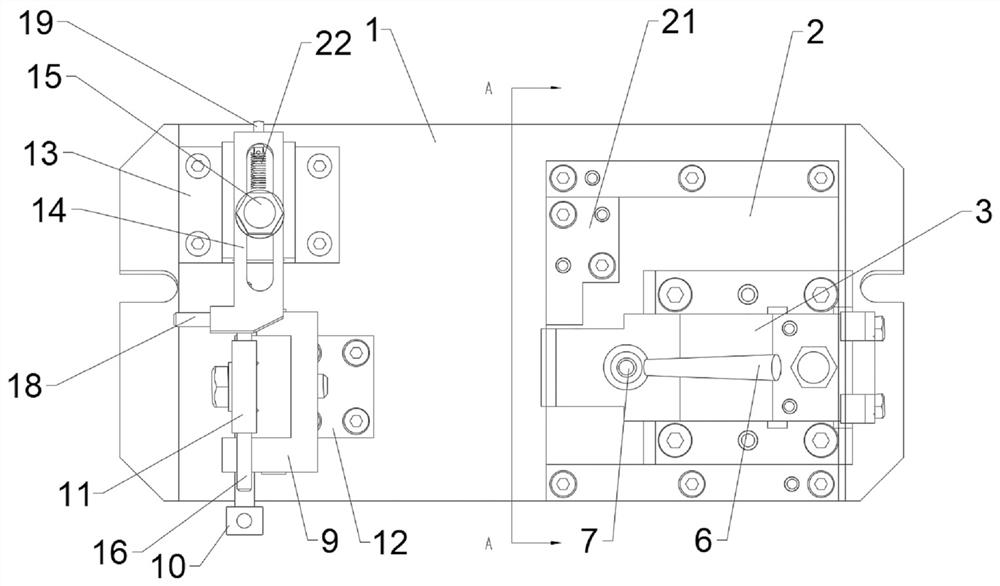

[0040] Such as Figure 1-Figure 4 As shown, this embodiment provides a fixed tool for turbine blade processing, including: a base plate 1, a chuck, a lateral self-adaptive adjustment support assembly and a longitudinal self-adaptive adjustment support assembly.

[0041] The collet is used to clamp the mortise, and the collet is fixedly connected to one end of the bottom plate 1 . The lateral adaptive adjustment support assembly is used to support the back of the blade. The lateral adaptive adjustment support assembly is fixedly connected to one side of the other end of the bottom plate 1 , and the output end of the lateral adaptive adjustment support assembly abuts against the blade back. The longitudinal self-adaptive adjustment support assembly is used to support the blade shroud of the blade. The longitudinal self-adaptive adjustment support assembly is fixedly connected to the other side of the other end of the bottom plate 1, and the output end of the longitudinal self-ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com