High-aluminum egg-shell reinforced celadon and preparation method thereof

A high-alumina, celadon technology, applied in the field of porcelain preparation, can solve problems such as unfavorable routine production of daily-use porcelain, unfavorable thin-bore reinforced porcelain molding, and affecting the plasticity of blanks, so as to reduce thickness, increase bending strength, and save resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

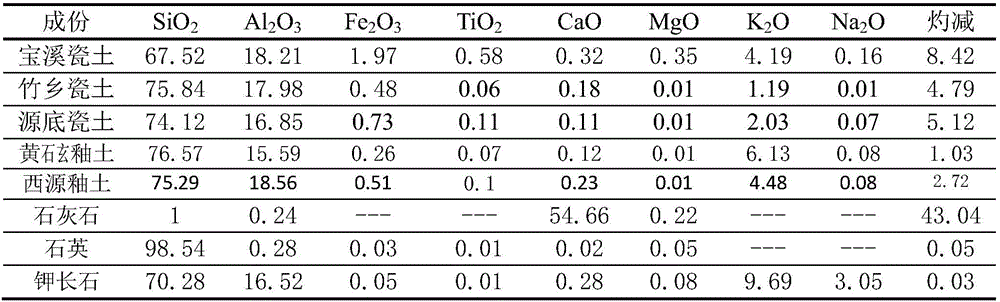

[0049] A kind of high-alumina thin tire reinforced celadon clay, which comprises the following components in terms of weight percentage: 25% of Baoxi porcelain clay; 23% of Zhuxiang porcelain clay, 25% of Yuandi porcelain clay, and ɑ-Al 2 o 3 Micro powder 35%, zirconia micro powder 2%, PVA 2%.

[0050] The preparation method of the above-mentioned high-alumina thin tire reinforced celadon mud comprises the following steps:

[0051] (a) Batching: according to the preset ratio, mix the raw materials of the above-mentioned high-alumina thin-body reinforced celadon mud for batching;

[0052] (b) Ball milling: Pour the prepared blank into a ball mill for ball milling to obtain mud, wherein the ratio of material to water is 1:1.5:1, the ball milling time is 15 hours, and the rotation speed is 30r / min;

[0053] (c) Sieving: the mud after ball milling is sieved with a vibrating sieve, the mesh size of the vibrating sieve is 180 mesh for the first layer and 200 mesh for the second la...

Embodiment 2

[0059] A kind of high-alumina thin tire reinforced celadon clay, which comprises the following components in terms of weight percentage: 35% of Baoxi porcelain clay; 13% of Zhuxiang porcelain clay, 35% of Yuandi porcelain clay, and ɑ-Al 2 o 3 Micro powder 20%, zirconia micro powder 4%, PVA 0.5%.

[0060] The same method as in Example 1 was used to prepare the above-mentioned high-alumina thin body reinforced celadon mud.

Embodiment 3

[0062] A kind of high-alumina thin tire reinforced celadon clay, which includes the following components in terms of weight percentage: 30% of Baoxi porcelain clay; 15% of Zhuxiang porcelain clay, 28% of Yuandi porcelain clay, and ɑ-Al 2 o 3 Micro powder 25%, zirconia micro powder 2%, PVA 1%.

[0063] The same method as in Example 1 was used to prepare the above-mentioned high-alumina thin body reinforced celadon mud.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com