Full-automatic excitation rotor winding machine

A technology for exciting rotors and winding machines, which is applied in the field of fully automatic exciting rotor winding machines, can solve the problems of low production efficiency of semi-automatic winding machines, achieve reduced labor costs and labor intensity, stable performance, and high equipment utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than Full examples.

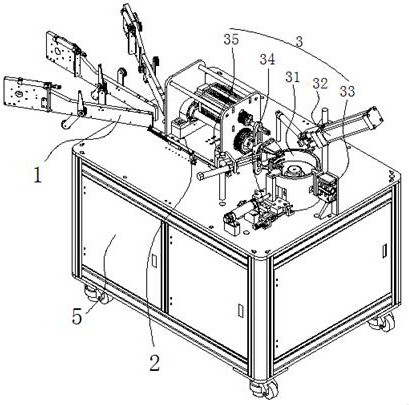

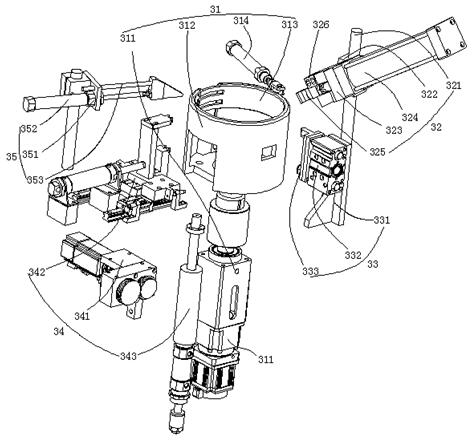

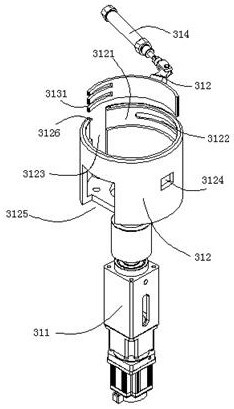

[0029]Please refer to the accompanying drawings: a fully automatic excitation rotor winding machine, including a frame 5, a tensioning unit 1, a winding unit 2, and a mold unit 3. Wherein: the frame 5 can usually be made of metal materials such as steel and aluminum. The tensioning unit 1, the winding unit 2, and the mold unit 3 are arranged in a vertical order on the top of the frame 5; the tensioning unit 1 is used to automatically correct the copper wire, and make it Speed output, and at the same time provide surplus wire for the copper wire cutting; the winding unit 2 is used to arrange the copper wires closely on the rotor with certain rules; the mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com