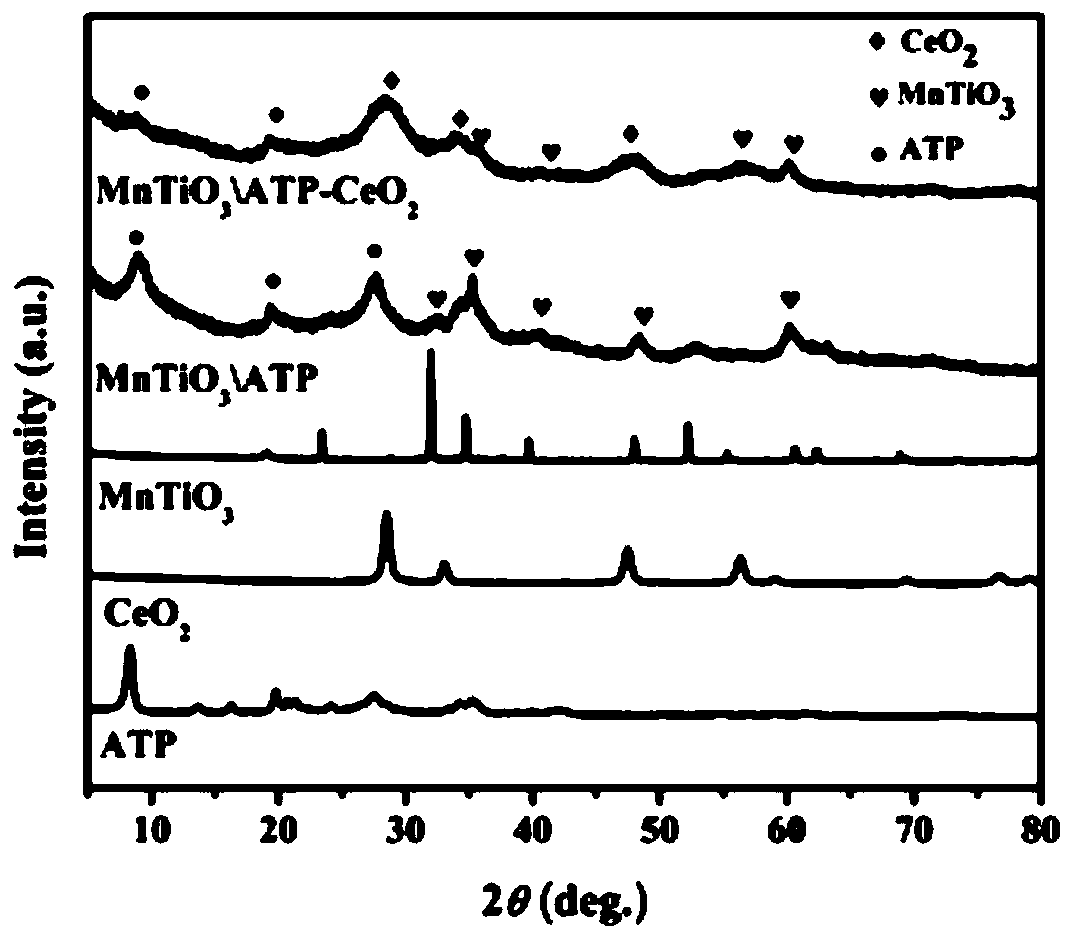

Flake manganese titanate coated attapulgite loaded ceo 2 Low-temperature photo-scr denitrification catalyst and preparation method thereof

A flake manganese titanate-coated, denitration catalyst technology, applied in the field of flue gas denitration, can solve the problems of insufficient low-temperature activity, enhance the redox ability of the catalyst, reduce the reaction temperature, etc., achieve excellent anti-SO2 performance, enhance redox ability, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Dissolve 1.00g of manganese acetate tetrahydrate in 20ml of absolute ethanol to obtain solution A, dissolve 1.38g of tetrabutyl titanate in 20ml of acetylacetone to obtain solution B, mix A and B at room temperature and stir evenly, and place in a water bath at 80°C Heat until the solution forms a sol state to obtain a sol solution.

[0027] (2) Fully disperse attapulgite in 5M sodium hydroxide solution to obtain attapulgite dispersion with a concentration of 2.5g / 100mL, mix 80ml attapulgite dispersion with all the sol in step (1) Stir magnetically for 2 hours, put it into a polytetrafluoroethylene hydrothermal kettle with a volume capacity of 100ml (the mixed solution does not exceed 80% of the capacity of the hydrothermal kettle), and perform a hydrothermal reaction at 160°C for 24 hours, then suction filter, wash, and dry Manganese titanate-coated attapulgite (MnTiO 3 \ATP).

[0028] (3) all the MnTiO prepared in step (2) 3 \ATP was ground and sieved, disperse...

Embodiment 2

[0033] (1) Dissolve 1.00g of manganese acetate tetrahydrate in 20ml of absolute ethanol to obtain solution A, dissolve 1.38g of tetrabutyl titanate in 20ml of acetylacetone to obtain solution B, mix A and B at room temperature and stir evenly, and place in a water bath at 80°C Heat until the solution forms a sol state to obtain a sol solution.

[0034] (2) Fully disperse attapulgite in 5M sodium hydroxide solution to obtain a dispersion with a concentration of 3.75g / 100mL, mix 80ml of attapulgite dispersion with all the sol in step (1) and magnetically stir for 2h , put it into a polytetrafluoroethylene hydrothermal kettle with a volume capacity of 100ml (the mixed solution does not exceed 80% of the capacity of the hydrothermal kettle), and after hydrothermal reaction at 160°C for 24 hours, suction filtration, washing, and drying make titanium Attapulgite coated with manganese oxide (MnTiO 3 \ATP).

[0035] (3) all the MnTiO prepared in step (2) 3 \ATP was ground and sieve...

Embodiment 3

[0037] (1) Dissolve 1.00g of manganese acetate tetrahydrate in 20ml of absolute ethanol to obtain solution A, dissolve 1.38g of tetrabutyl titanate in 20ml of acetylacetone to obtain solution B, mix A and B evenly, and heat in a water bath at 80°C until The solution forms a sol state to obtain a sol solution.

[0038] (2) Fully disperse attapulgite in 5M sodium hydroxide solution to obtain a dispersion with a concentration of 2.5g / 100mL, mix 80ml of attapulgite dispersion with all the sol in step (1) and magnetically stir for 2h , put it into a polytetrafluoroethylene hydrothermal kettle with a volume capacity of 100ml (the mixed solution does not exceed 80% of the capacity of the hydrothermal kettle), and after hydrothermal reaction at 160°C for 24 hours, suction filtration, washing, and drying make titanium Attapulgite coated with manganese oxide (MnTiO 3 \ATP).

[0039] (3) all the MnTiO prepared in step (2) 3 \ATP was ground and sieved, dispersed in about 100ml deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com