Self-propulsion cutter suction dredger with bulbous bow

A cutter suction dredger, self-propelled technology, applied to special-purpose ships, ships, motor vehicles, etc., can solve problems such as difficult to arrange side thrusters, tight bow space, affecting ship maneuverability, etc. Effects of wave resistance and total resistance, increased layout space, and improved rapid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

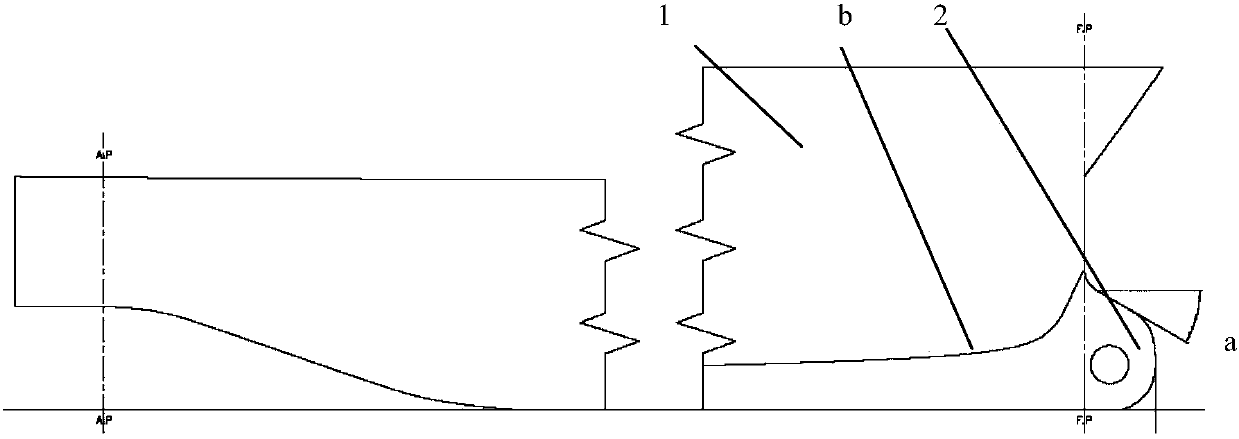

[0034] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 4 As shown, the length of the ship is 115m, the width of the ship is 27.8m, and the length of the bulbous bow 2 is preferably 2.4% of the length of the ship,

[0035] In further embodiments of the present invention, see figure 1 As shown, from the perspective of the side shape, the upper surface of the bulbous bow 2 is specially designed, preferably with a downward slope of 30 degrees, so that the setting of the bulbous bow 2 will not affect the connection, disassembly and locking of the bow equipment. and other operations are affected.

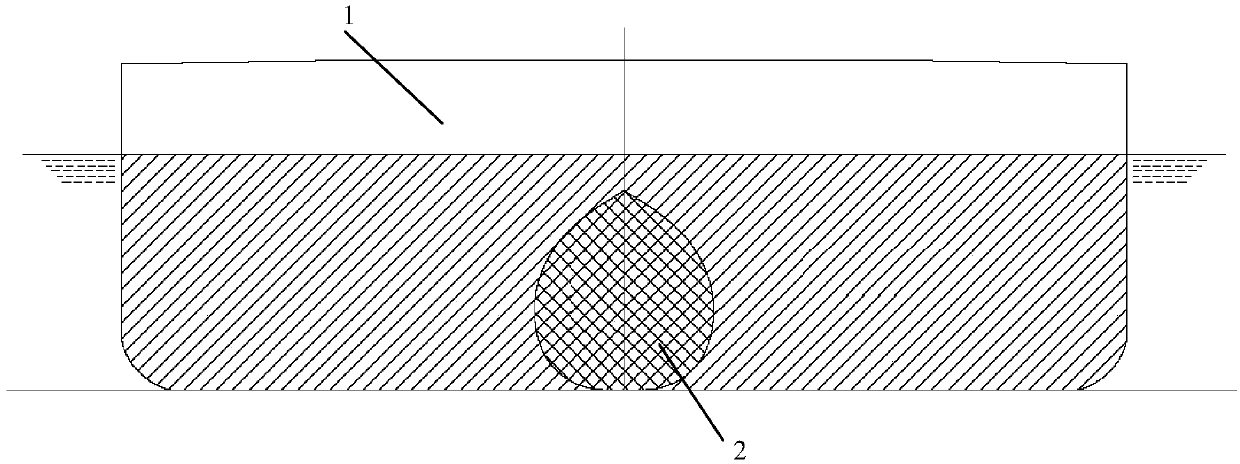

[0036] In further embodiments of the present invention, see figure 2 As shown, the ratio of the cross-sectional area of the bulbous bow 2 at the bow vertical line to the cross-sectional area of the midship below the waterline is preferably 0.11.

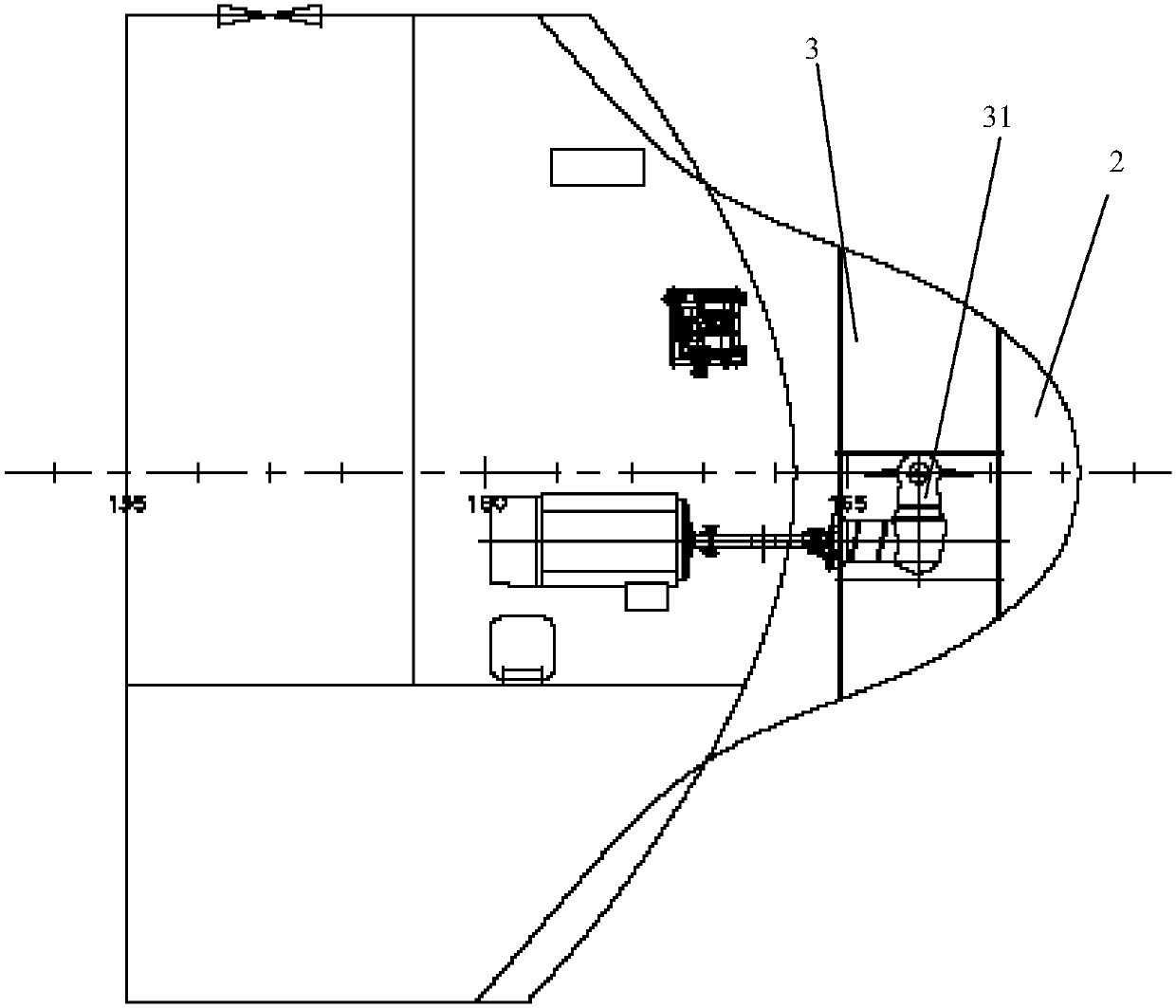

[0037] In further embodiments of the present invention, see Figure 4 As shown, a bow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com