Method for preparing metallocene polypropylene catalyst

A metallocene polypropylene and metallocene compound technology, applied in the field of preparation of metallocene polypropylene catalysts, can solve the problems of increasing the production cost of polypropylene products and restricting industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

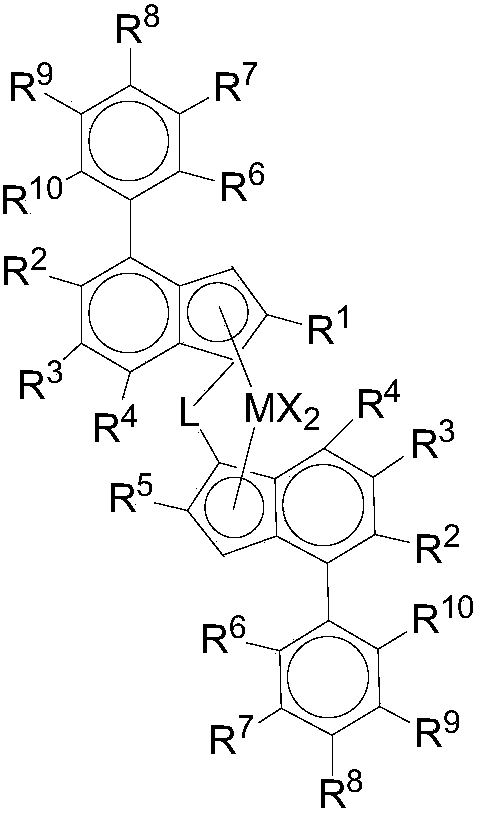

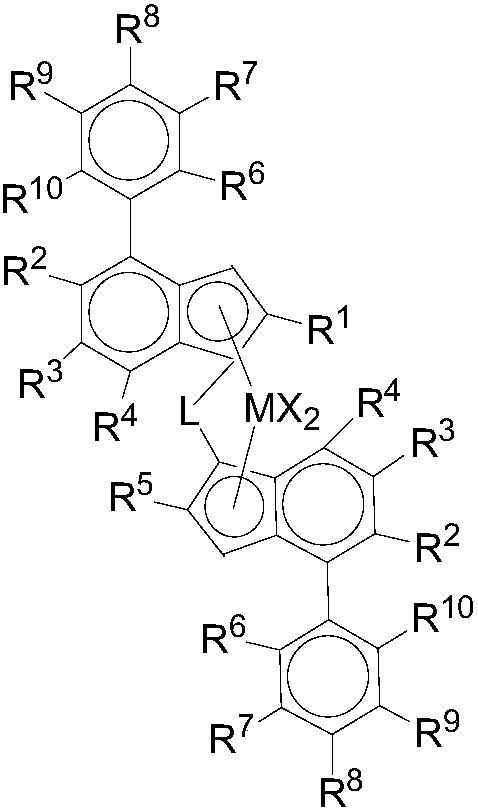

Image

Examples

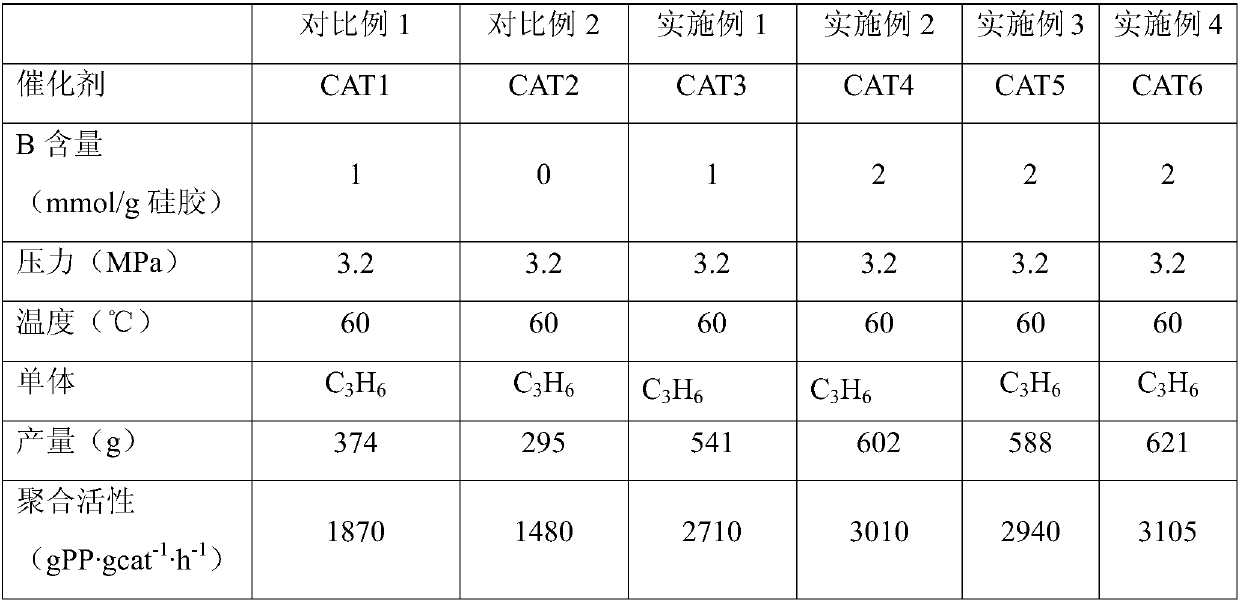

Embodiment 1

[0051] Accurately weigh 1 g of silica gel pretreated at 600 °C, suspend in 20 mL of toluene, add 1 mmol BF 3 solution, stirred at room temperature for 2h, and then the solid part was washed 3 times with 20mL toluene to obtain BF 3 Modified SiO 2 . Add 27mmol aluminoxane solution, stir at 50°C for 2h, then wash the solid part with 20mL toluene 3 times to obtain aluminoxane-modified SiO 2 . Then add 20ml of toluene, then add a certain amount of rac-dimethylsilanediylbis(2-methyl-4-phenylindenyl) zirconium dichloride, stir at room temperature for 2h, and wash the solid part with 20mL of toluene for 3 Once, the solvent was removed at room temperature to obtain the supported catalyst CAT3 (loaded zirconium amount: 5mgZr / gSiO 2 ).

[0052] polymerization process

[0053] 10 mmol TEA and 1200 g liquid propylene were added to a 4 L stainless steel jacketed reactor equipped with a magnetic drive stirrer and catalyst feeder. After stirring for 10 minutes, a total of 100 mg of catal...

Embodiment 2

[0055] Catalyst CAT4 preparation method is the same as embodiment 1, but adds 2mmol BF in every gram of silica gel 3 solution.

Embodiment 3

[0057] Accurately weigh 1 g of silica gel pretreated at 600 °C, suspend in 20 mL of toluene, add 2 mmol BF 3 solution, stirred at room temperature for 2h, and then the solid part was washed 3 times with 20mL toluene to obtain BF 3 Modified SiO 2 . Add 27mmol aluminoxane solution, stir at 50°C for 2h, then wash the solid part with 20mL toluene 3 times to obtain aluminoxane-modified SiO 2 . Then add 20ml of toluene, and then add a certain amount of rac-CH 2 (2-tert-butyl-1-indenyl) 2 ZrMe 2 , stirred at room temperature for 2h, the solid part was washed 3 times with 20mL toluene, and the solvent was removed at room temperature to obtain the supported catalyst CAT5 (zirconium loading: 5mgZr / gSiO 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com