Hot dipping method for zinc-aluminum coating of bridge cable

A bridge cable and aluminum coating technology, applied in the field of bridge cables, to achieve the effect of ensuring the aluminum content requirements and increasing the line speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

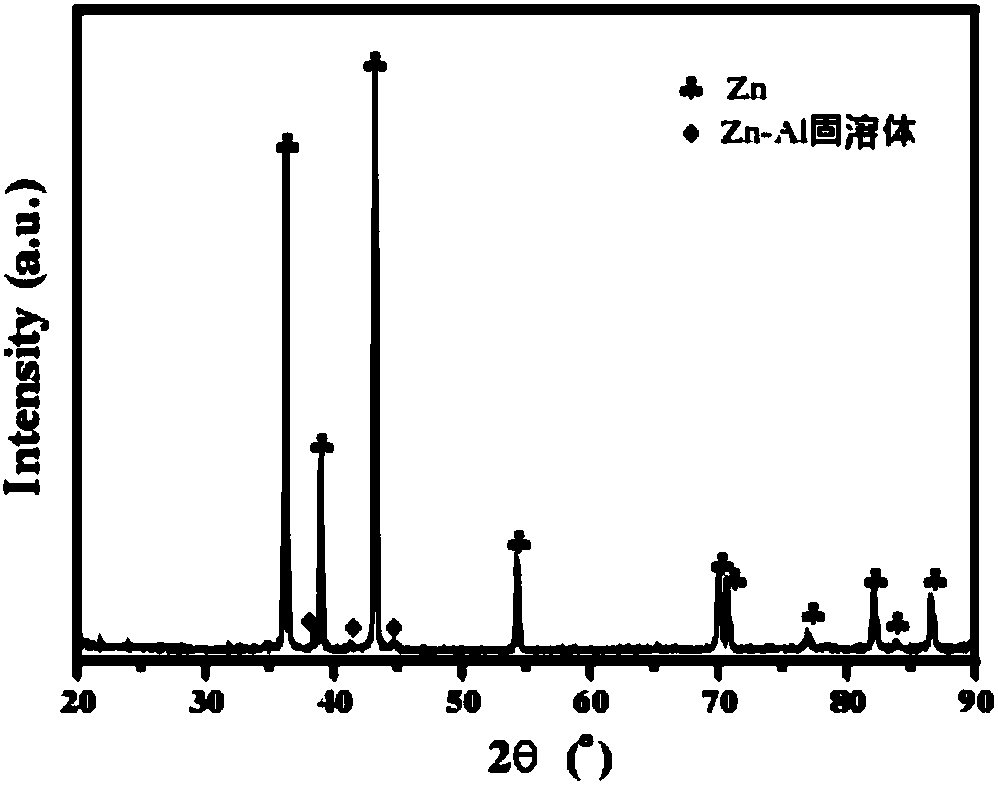

[0032] The invention relates to a hot-dip method for zinc-aluminum coating of a bridge cable. Steel wires are firstly galvanized in a zinc furnace, and then galvanized in a zinc-aluminum alloy furnace. In the zinc-aluminum alloy, the aluminum content is 10wt%, the wire running speed is 30m / min, the hot-dip temperature is controlled at 450°C, and the zinc-aluminum alloy coated steel wire is wiped with nitrogen gas.

Embodiment 2

[0034] The invention relates to a hot-dip method for zinc-aluminum coating of a bridge cable. Steel wires are firstly galvanized in a zinc furnace, and then galvanized in a zinc-aluminum alloy furnace. In the zinc-aluminum alloy, the aluminum content is 6.5wt%, the wire running speed is 35m / min, the hot-dip temperature is controlled at 430°C, and the zinc-aluminum alloy coated steel wire is wiped with nitrogen gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com