Shift cable noise reduction device

A shift cable and noise reduction technology, which is applied in the direction of transmission control, shaft and bearing, linear motion shaft, etc., can solve the problem of no noise reduction effect, achieve noise reduction processing, and realize the effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

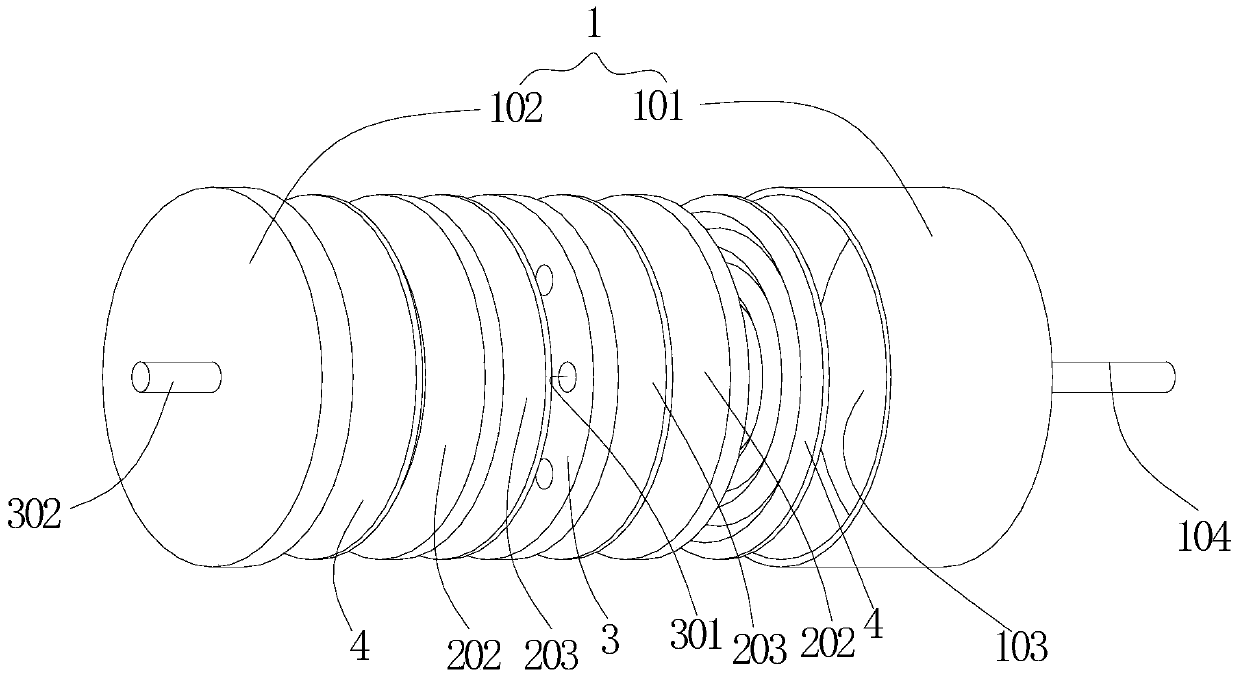

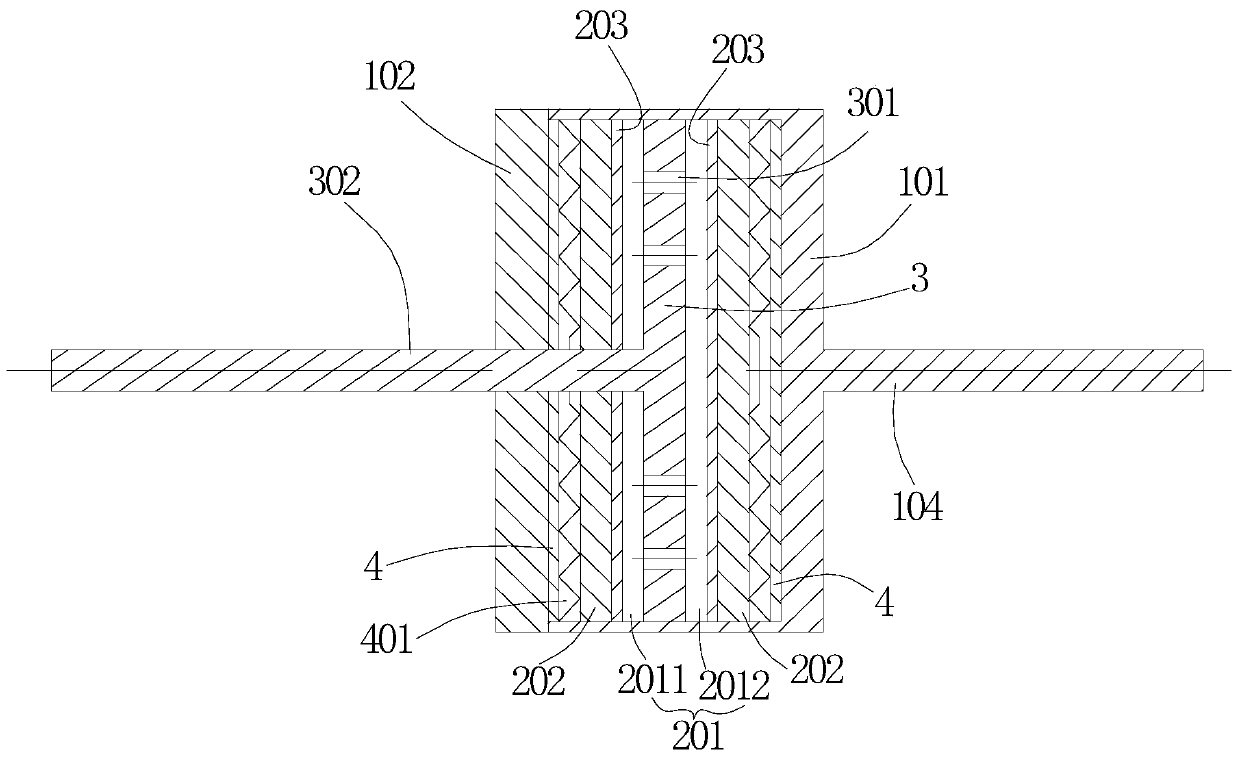

[0034] This embodiment relates to a gear shift cable noise reduction device, the overall structure of which includes a housing with an accommodating cavity formed therein, a sealing part, a sliding part, a first connecting part and a second connecting part. Depend on figure 1 and figure 2 It can be seen that the housing 1 has a cylindrical shape as a whole, and it is composed of a main body 101 with a U-shaped axial cross-section and a cover 102 fixedly connected to the opening of the main body 101 by a cover buckle. The hollow interior of the main body 101 is An accommodating cavity 103 is formed. In subject 101, with figure 1 On the right side end surface of the state shown, there is a first connecting part 104 fixedly connected, the first connecting part 104 is rod-shaped, and in order to improve the overall use effect, the axis of the first connecting part 104 coincides with the center line of the housing 1 . The first connecting portion 104 is used to be fixedly conn...

Embodiment 2

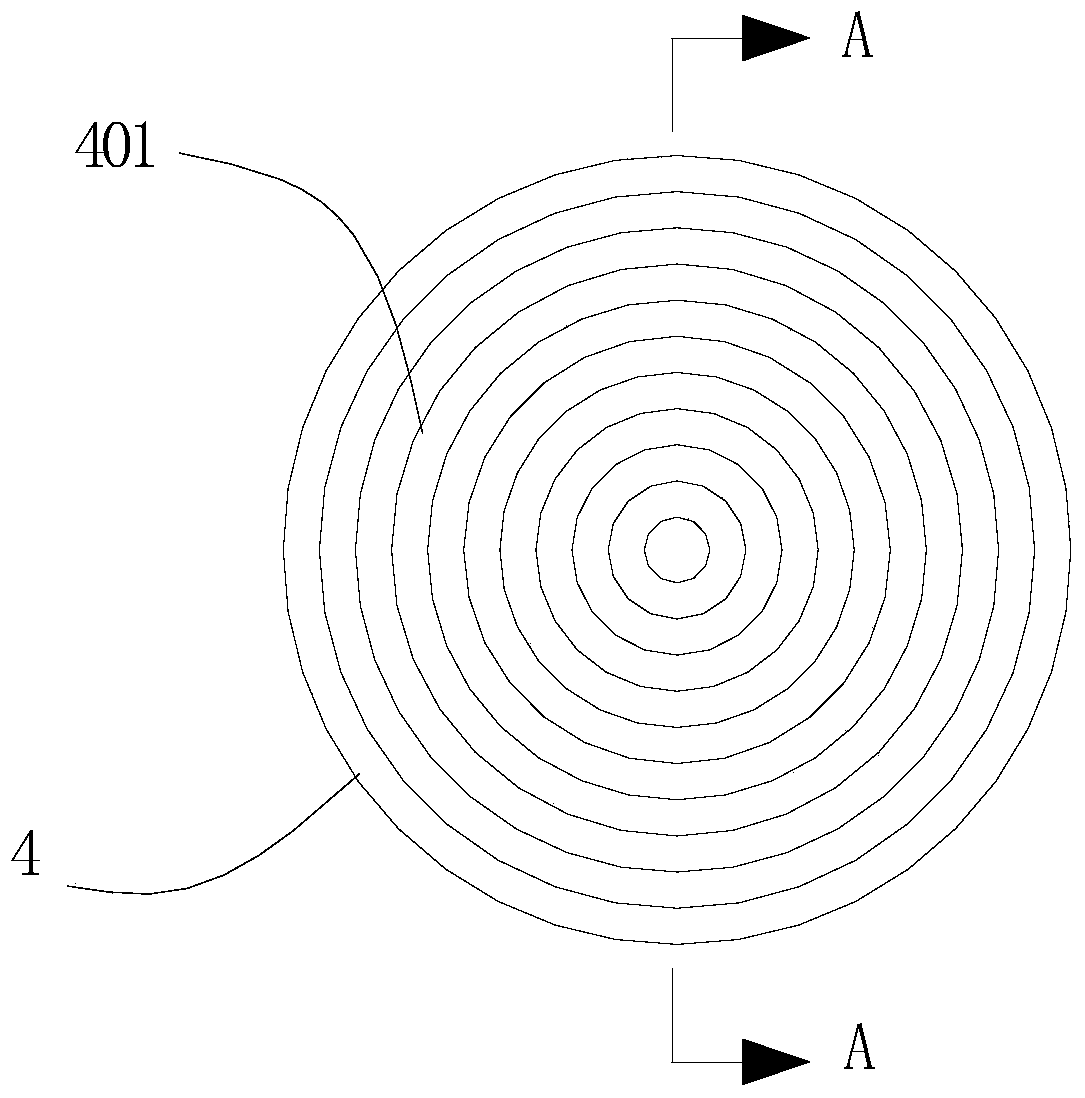

[0043] This embodiment also relates to a shift cable noise reduction device, which is basically the same as Embodiment 1, except that, on the support portion 4, a secondary support portion 402 facing the isolation plate 202 is formed; Figure 5 so Figure 4 The state shown shows a schematic structural view of the support part 4. It can be seen that the axial length of the secondary support part 402 is smaller than the axial length of the primary support part 401, that is, the secondary support part 402 is also an annular sawtooth In this way, based on the description of the first embodiment, when the excitation is large, after the isolation plate 202 compresses the primary support portion 401, it can continue to compress the secondary support portion 401. The first-level support part 402 is formed to be squeezed sequentially. In order to better improve the noise reduction effect, the saw-tooth gap of the second-level support part 402 is smaller than the saw-tooth gap on the fi...

Embodiment 3

[0045] This embodiment also relates to a gear shift cable noise reduction device, which is basically the same as Embodiment 1, the difference is that the Figure 6 As can be seen from the illustration, the setting of the support part 4 is canceled in this embodiment, and the noise reduction effect is achieved only through the gas in the sealed cavity 201 , which can produce a better noise reduction effect on high-frequency noise excitation.

[0046] It is worth noting that, by Figure 6 It can be seen that the sealed cavity 201 can not only be formed by two isolation plates 202 spaced apart, but also the two isolation plates can be discarded, and the accommodating cavity can be directly used as the sealed cavity. In addition, in Embodiment 1, the sealing part may also be a separate component arranged in the accommodating cavity, such as adopting a box structure, etc., which may not cooperate with the inner wall of the housing 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com