Laser-tracker-based calibration method for six-degree-of-freedom robot tool coordinate system

A technology of tool coordinate system and laser tracker, which is applied in the field of six-degree-of-freedom industrial robots, can solve the problems of complex operation and low precision, and achieve the effects of simple operation, high precision, data processing and intuitive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The calibration method of the six-degree-of-freedom robot tool coordinate system based on the laser tracker of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

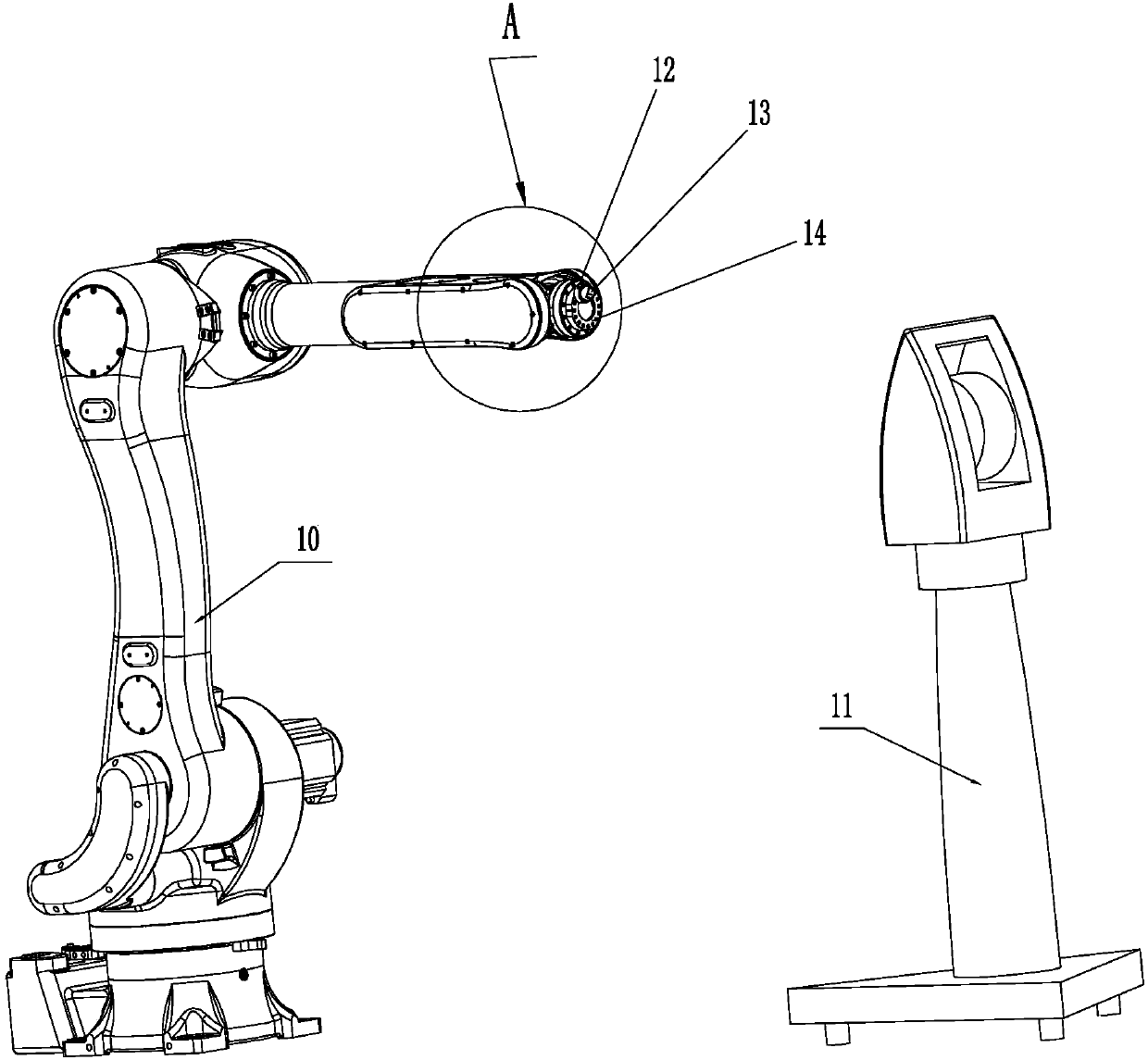

[0034] Such as figure 1 with figure 2 As shown, in this specific embodiment, the calibration method of the six-degree-of-freedom robot tool coordinate system based on the laser tracker of the present invention includes the following steps:

[0035] (1) Place the laser tracker 11 at 3 meters directly in front of the robot body 10, and preheat it in advance;

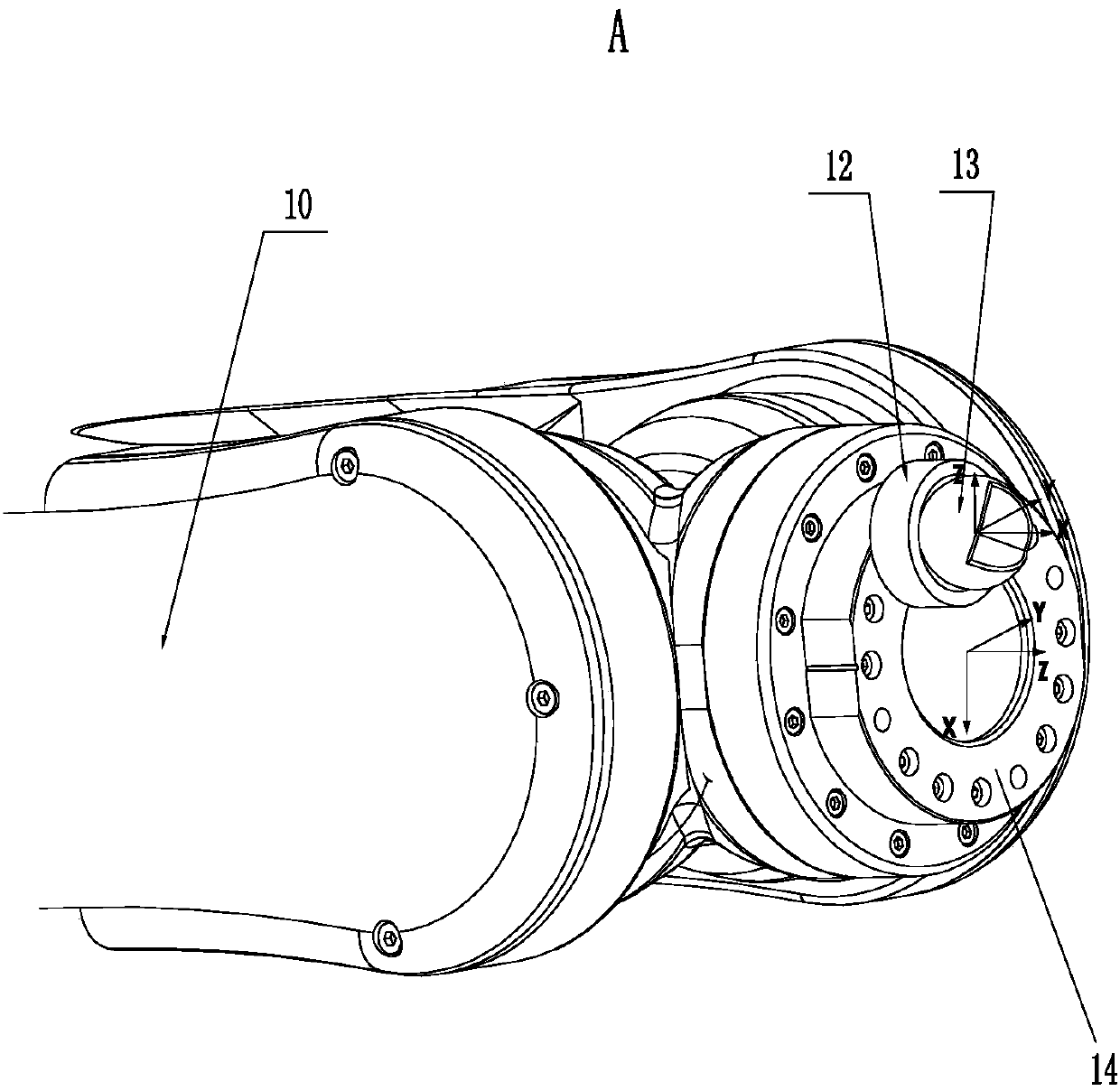

[0036] (2) fixedly install the target ball base 12 and the target ball 13 on the flange 14 at the end of the robot body 10;

[0037] (3) run SA (Spatial Analyzer) software and connect laser tracker 11;

[0038] (4) adjust the robot body 10 to the non-singular point position near the zero position, and record the spatial position of the target ball 13 under this postur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com