A nanoparticle-based anisotropic two-phase composite magnet and its preparation method

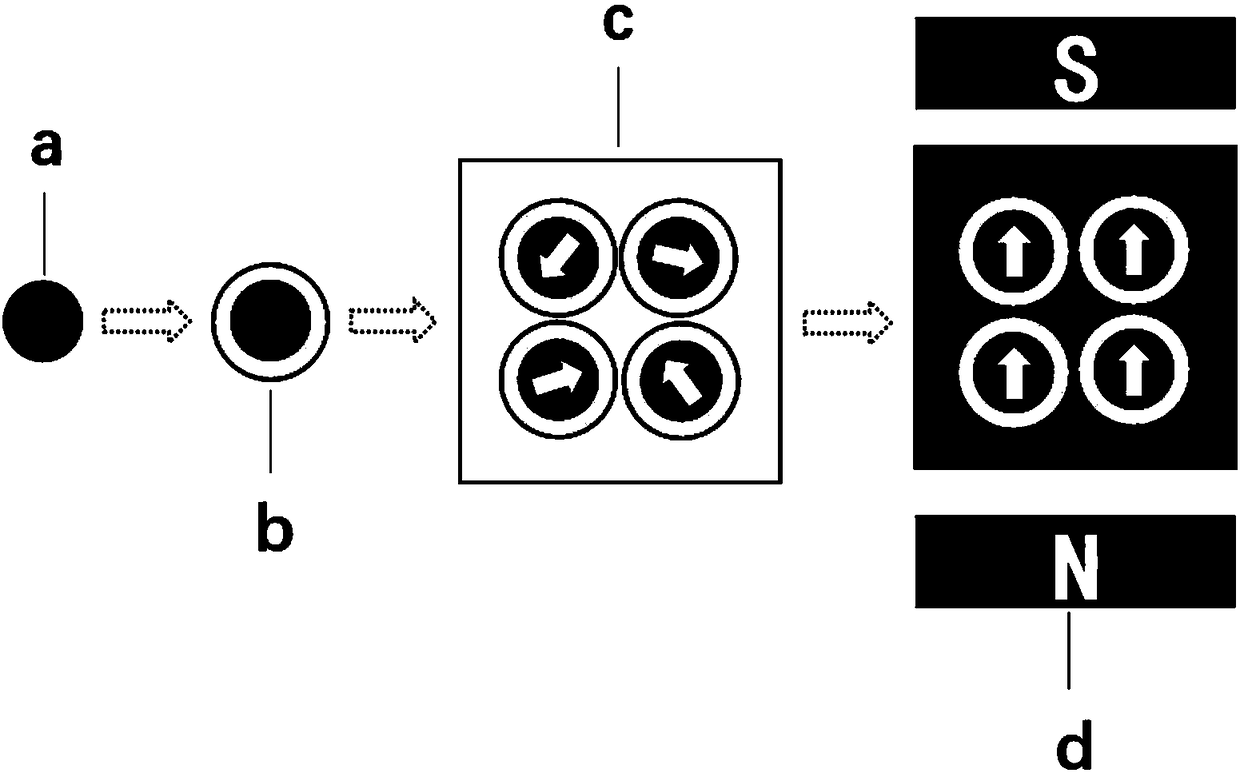

A nanoparticle and composite magnet technology, applied in magnetic objects, nanotechnology, nanotechnology, etc., can solve the problems of complex preparation methods of soft and hard magnetic exchange coupling nanoparticles, reduced magnetic crystal anisotropy, and reduced driving force of orientation , to achieve the effect of improving anisotropy performance, simple equipment, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1.1 Take platinum acetylacetonate (Pt(acac) 2 ) 0.1g, 0.8ml oleylamine, and 0.8ml oleic acid were dissolved in 10m1-octadecene, stirred thoroughly, and heated to 120°C under the protection of nitrogen to obtain solution A.

[0039] 1.2 Take iron pentacarbonyl (Fe(CO) 5 ) 0.072ml, injected into the above-mentioned A solution with a disposable syringe to obtain the mixed solution B, and then heated the solution B to 300° C. for 10 minutes under the protection of nitrogen. After the reaction was completed, the above reaction solution was centrifuged and washed 5 times with acetone and n-hexane to obtain fcc phase FePt nanoparticles.

[0040] 1.3 Take 0.03 g of the above-mentioned fcc phase nanoparticles, magnesium acetylacetonate dihydrate (Mg(acac) 2 2H 2 (0) 0.6 g, 6 ml of oleylamine, and 1.5 ml of oleic acid were dissolved in 15 ml of bibenzyl ether to obtain a mixed solution, and the mixed solution was heated to 300° C. for 1 hour under nitrogen protection. After t...

Embodiment 2

[0047] 2.1 Take platinum acetylacetonate (Pt(acac) 2 ) 0.1 g, 0.8 ml of oleylamine, and 0.8 ml of oleic acid were dissolved in 10 ml of 1-octadecene, stirred thoroughly, and heated to 120° C. under the protection of nitrogen to obtain solution A.

[0048] 2.2 Take iron pentacarbonyl (Fe(CO) 5 ) 0.072ml, injected into the above-mentioned A solution with a disposable syringe to obtain the mixed solution B, and then heated the solution B to 300° C. for 10 minutes under the protection of nitrogen. After the reaction was completed, the above reaction solution was centrifuged and washed 5 times with acetone and n-hexane to obtain fcc phase FePt nanoparticles.

[0049] 2.3 Take 0.04 g of the above fcc phase nanoparticles, magnesium acetylacetonate dihydrate (Mg(acac) 2 2H 2 (0) 0.6 g, 6 ml of oleylamine, and 1.5 ml of oleic acid were dissolved in 15 ml of bibenzyl ether to obtain a mixed solution, and the mixed solution was heated to 300° C. for 1 hour under nitrogen protection. ...

Embodiment 3

[0056] 3.1 Take platinum acetylacetonate (Pt(acac) 2 ) 0.1 g, 0.8 ml of oleylamine, and 0.8 ml of oleic acid were dissolved in 10 ml of 1-octadecene, stirred thoroughly, and heated to 120° C. under the protection of nitrogen to obtain solution A.

[0057] 3.2 Take iron pentacarbonyl (Fe(CO) 5 ) 0.072ml, injected into the above-mentioned A solution with a disposable syringe to obtain the mixed solution B, and then heated the solution B to 300° C. for 10 minutes under the protection of nitrogen. After the reaction was completed, the above reaction solution was centrifuged and washed 5 times with acetone and n-hexane to obtain fcc phase FePt nanoparticles.

[0058] 3.3 Take 0.04 g of the above fcc phase nanoparticles, magnesium acetylacetonate dihydrate (Mg(acac) 2 2H 2 (0) 0.4 g, 6 ml of oleylamine, and 1.5 ml of oleic acid were dissolved in 30 ml of bibenzyl ether to obtain a mixed solution, and the mixed solution was heated to 300° C. for 0.5 hours under nitrogen protection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com