Tubular bus-bar support device

A technology of supporting device and tube busbar, applied in the directions of busbar installation, cable installation, electrical components, etc., can solve the problem of easy loosening of the tube busbar clamp, and achieve the effect of reducing damage, avoiding easy loosening, and reducing jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

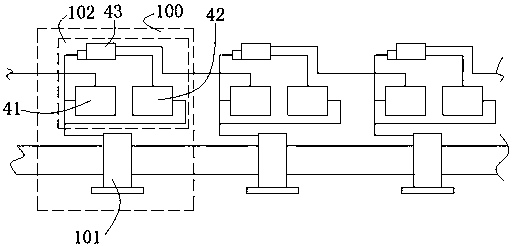

[0020] Embodiments of the pipe busbar support device in the present invention: such as Figure 1 to Figure 3 As shown in the figure, the support device is a pipe bus support system applied in high-voltage power transmission. And the hydraulic control part 102 two parts.

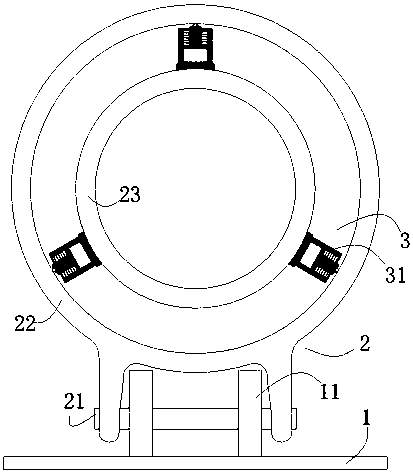

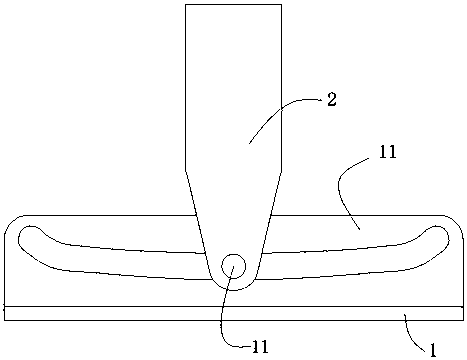

[0021] The support part 101 is mainly composed of three parts: the base 1 , the bracket 2 and the floating mechanism 3 . The main body of the base 1 is a flange plate made of ABS plastic material. The top of the base 1 is protruded with convex ribs 11 extending front and rear. There are two convex ribs 11 and they are parallel to each other and of equal length. The front and rear ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com