Power conversion circuit board, and electric compressor

A technology for power conversion and circuit substrates, applied to circuit devices, machines/engines, printed circuit components, etc., to reduce the impact and achieve high withstand voltage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

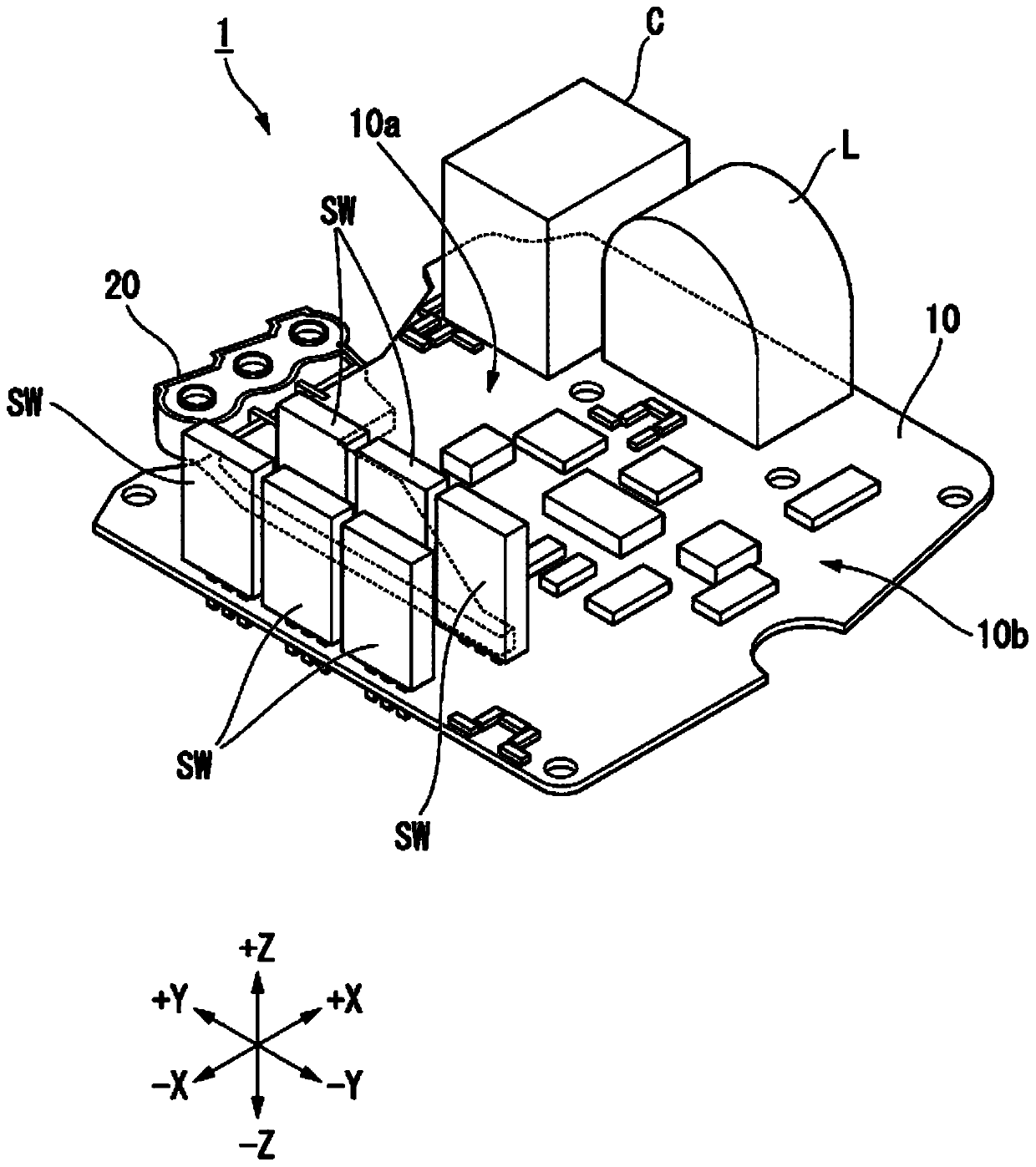

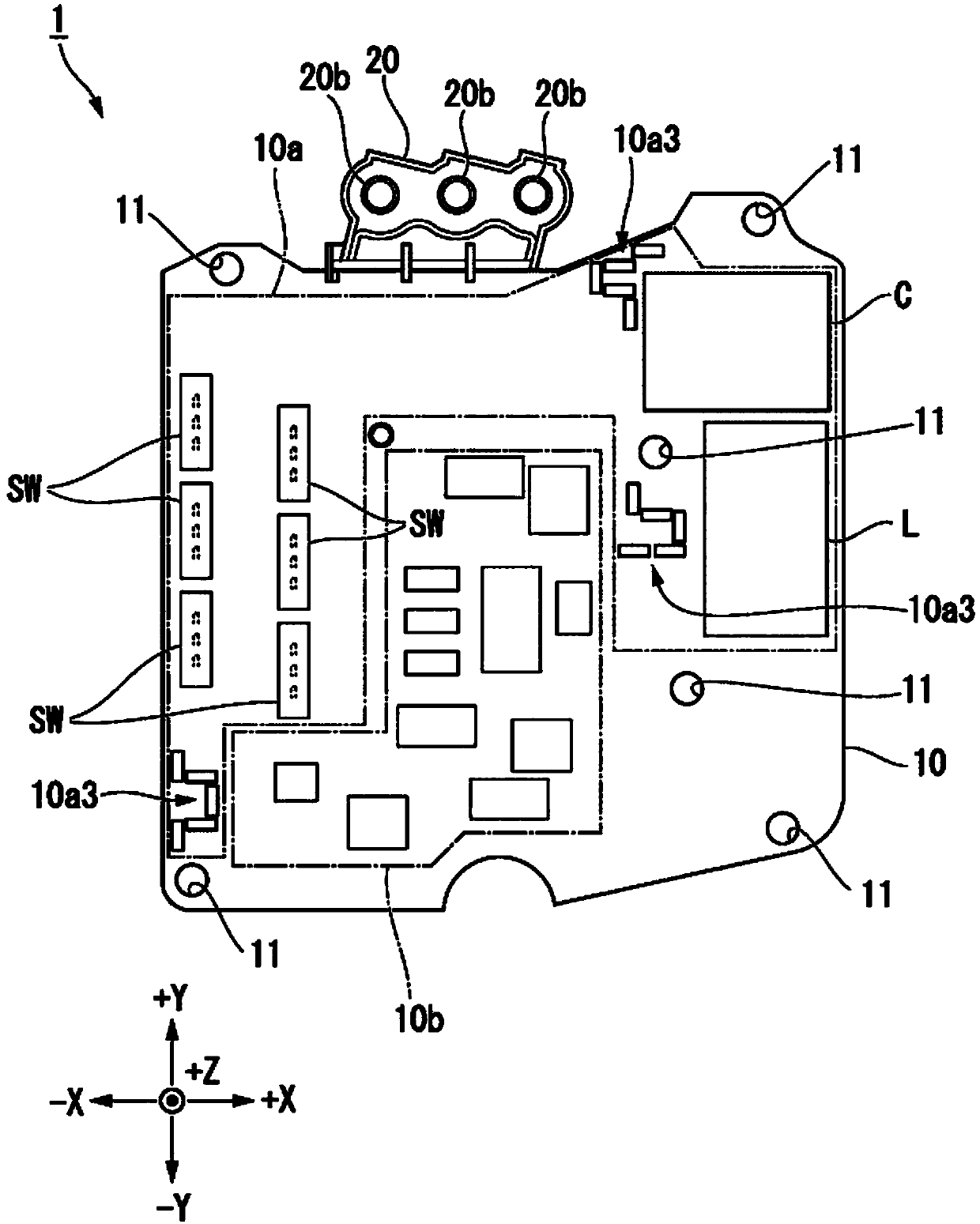

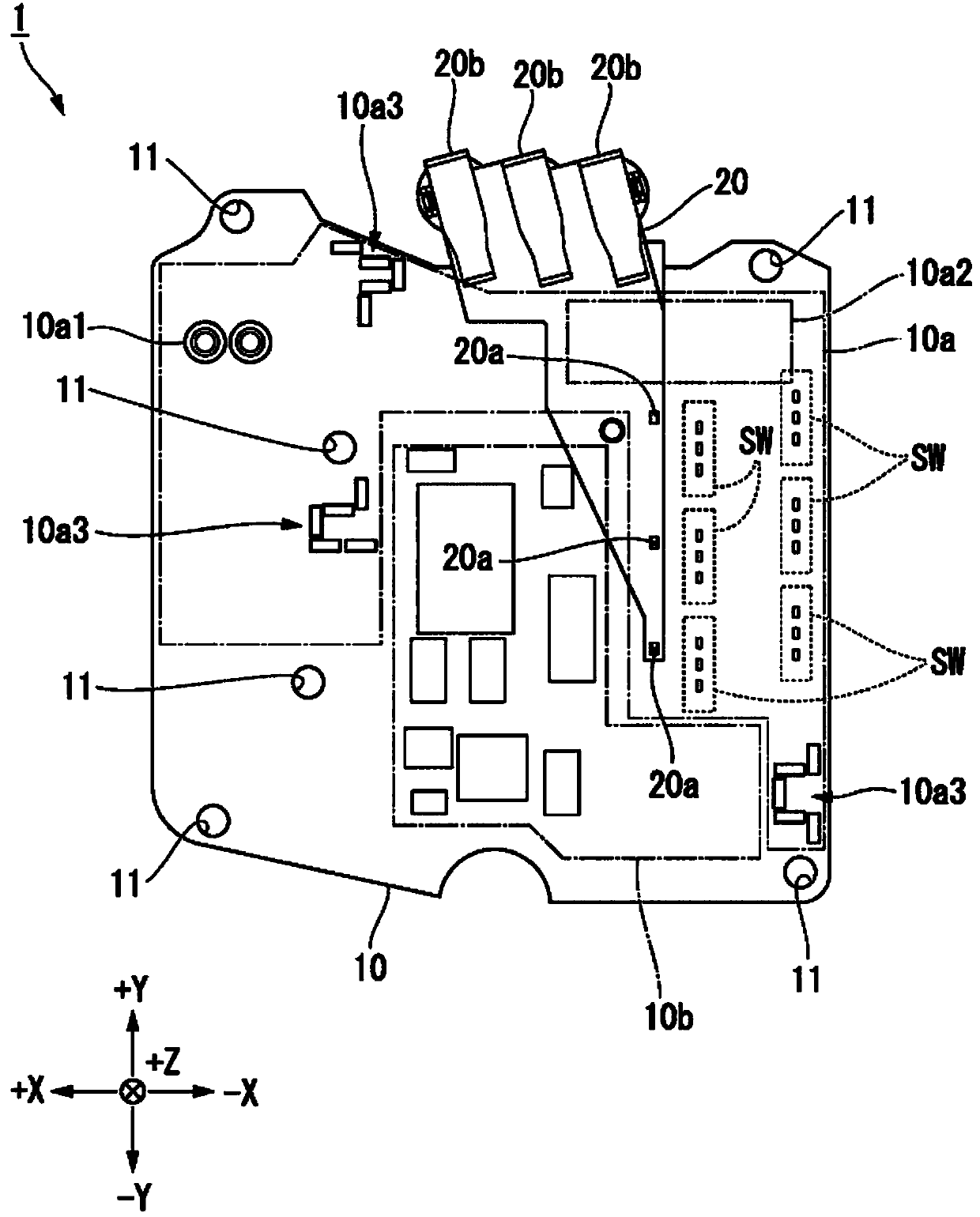

[0042] Below, refer to Figure 1 to Figure 7 The circuit board for power conversion according to the first embodiment will be described.

[0043] (the whole frame)

[0044] figure 1 It is a perspective view of the circuit board for electric power conversion concerning 1st Embodiment.

[0045] in addition, figure 2 It is a top view of the circuit board for power conversion concerning 1st Embodiment.

[0046] in addition, image 3 It is a bottom view of the circuit board for power conversion concerning 1st Embodiment.

[0047] in addition, Figure 4 It is a side view of the circuit board for power conversion concerning 1st Embodiment.

[0048] in addition, Figure 5 It is a front view of the circuit board for electric power conversion concerning 1st Embodiment.

[0049] The power conversion circuit board 1 according to the first embodiment is a circuit board constituting an inverter that converts DC power supplied from outside through input terminals (described later) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com