Wall breaking machine, control method and control system therefor

A control method and control system technology, applied in the field of kitchen utensils, can solve the problems of increasing the cost of the wall breaking machine, sticking the bottom, sticking the bottom, etc., and achieve the effect of reducing energy consumption, reducing energy consumption, and avoiding the effect of material sticking to the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

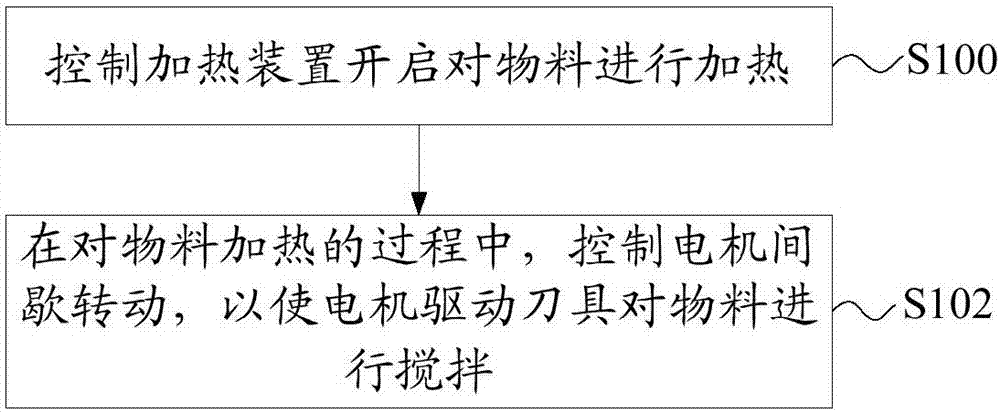

[0052] Such as figure 1 As shown, a control method for a wall breaking machine includes the following steps:

[0053] Step S100, controlling the heating device to turn on to heat the material;

[0054] Step S102, in the process of heating the material, control the motor to rotate intermittently, so that the motor drives the cutter to stir the material.

[0055] The control method of the wall breaking machine provided by the above-mentioned embodiments of the present invention includes controlling the heating device to be turned on to heat the material, and controlling the motor to rotate intermittently during the process of heating the material so that the motor drives the cutter connected to it Rotate, stir the material, realize the tumbling of the material, make the material evenly heated, and avoid the phenomenon of sticking to the bottom, sticking to the wall and sticking to the bottom of the material during the heating process. Preferably, when the heating device is turn...

Embodiment 2

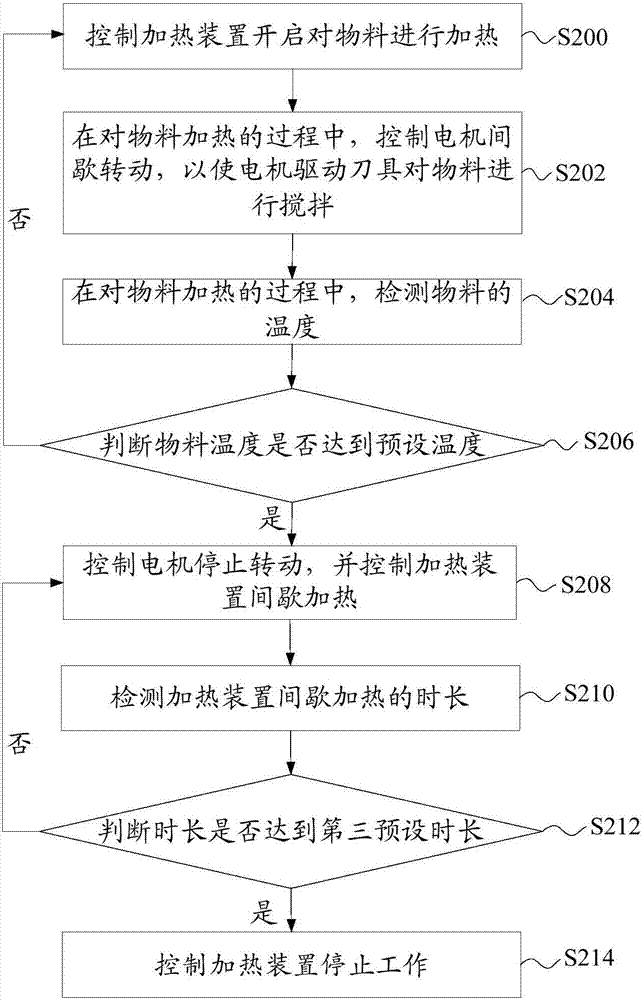

[0064] Such as figure 2 As shown, the control method of the broken wall machine in the working mode I for cooking porridge includes the following steps:

[0065] Step S200, controlling the heating device to turn on to heat the material;

[0066] Step S202, during the process of heating the material, control the motor to rotate intermittently, so that the motor drives the cutter to stir the material;

[0067] Step S204, during the process of heating the material, detecting the temperature of the material;

[0068] Step S206, judging whether the temperature of the material reaches the preset temperature;

[0069] Step S208, if the temperature of the material reaches the preset temperature, control the motor to stop rotating, and control the heating device to heat intermittently;

[0070] Step S210, detecting the duration of intermittent heating by the heating device;

[0071] Step S212, judging whether the duration reaches the third preset duration;

[0072] Step S214, if ...

Embodiment 3

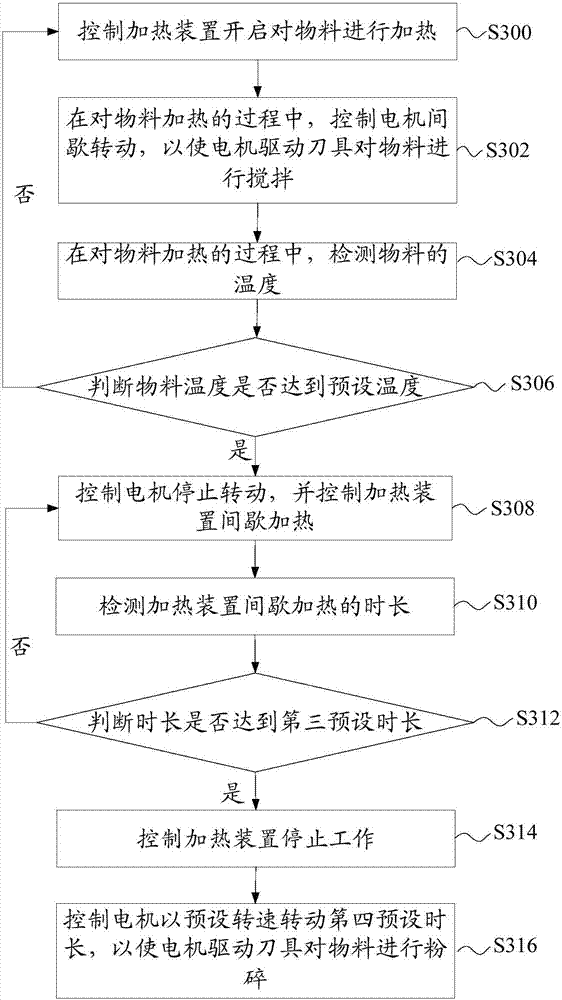

[0082] The wall breaking machine includes working mode II for making rice paste or soybean milk, such as image 3 As shown, the control method of the breaker under the working mode II includes the following steps:

[0083] Step S300, controlling the heating device to turn on to heat the material;

[0084] Step S302, during the process of heating the material, control the motor to rotate intermittently, so that the motor drives the cutter to stir the material;

[0085] Step S304, during the process of heating the material, detecting the temperature of the material;

[0086] Step S306, judging whether the temperature of the material reaches the preset temperature;

[0087] Step S308, if the temperature of the material reaches the preset temperature, control the motor to stop rotating, and control the heating device to heat intermittently;

[0088] Step S310, detecting the duration of intermittent heating by the heating device;

[0089] Step S312, judging whether the duration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com