Novel chemical tank washing device

A technology for cleaning devices and chemical tanks, applied in the direction of cleaning hollow objects, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of time-consuming and labor-intensive, etc., achieve simple structure, solve the problems of time-consuming and labor-consuming, and be convenient to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

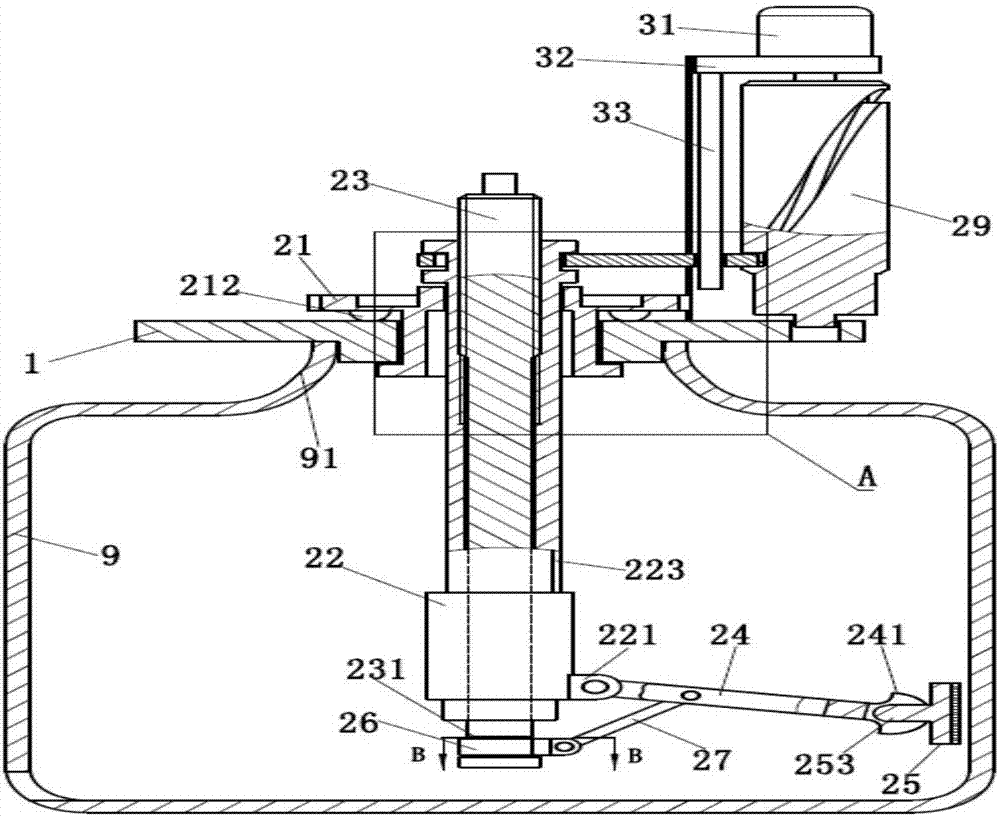

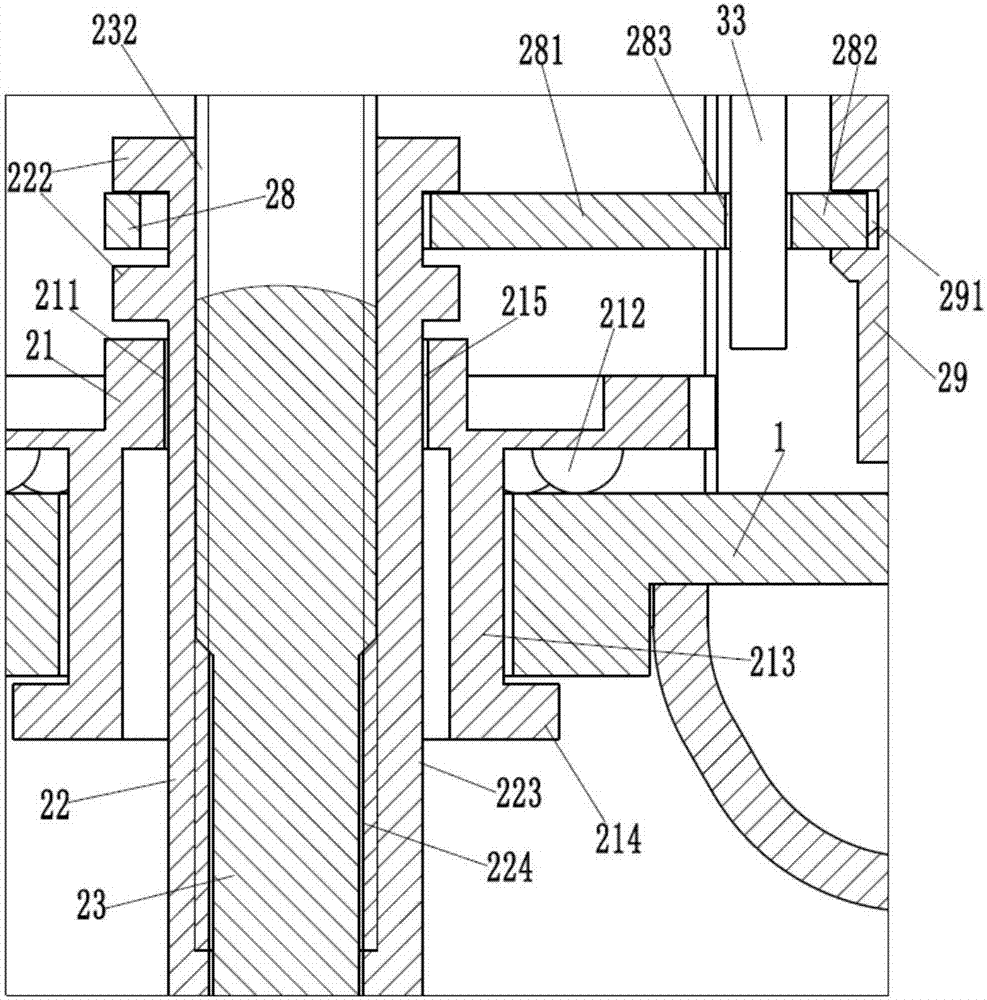

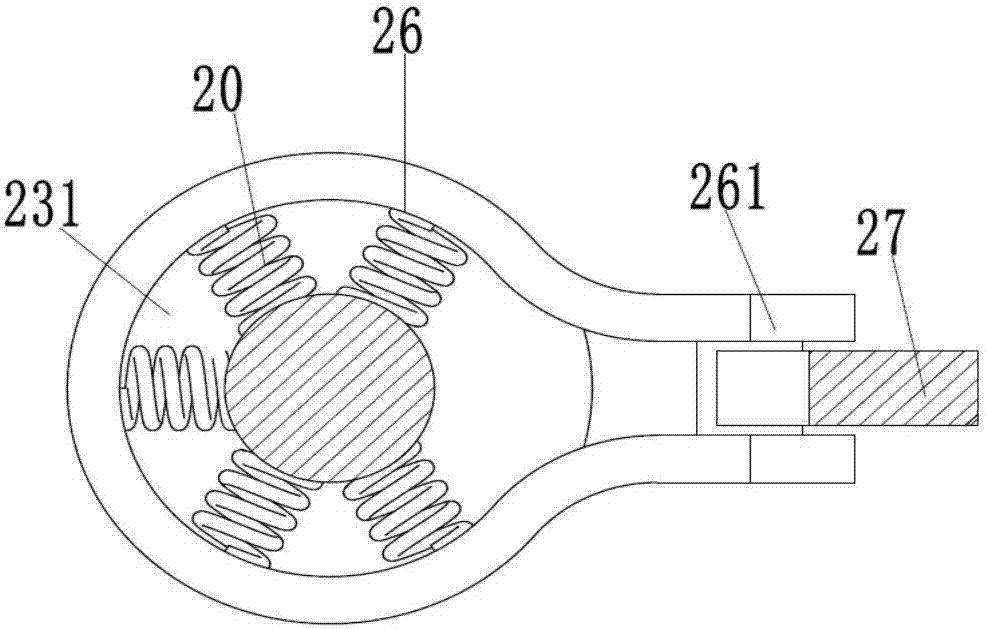

[0016] Examples, see e.g. Figure 1 to Figure 5 As shown, a novel chemical tank cleaning device includes a base 1, the base 1 is sleeved on the mouth 91 of the chemical tank 9, the middle part of the base 1 is hinged with a ratchet 21, and the ratchet 21 is formed with a through hole 211, The through hole 211 is sleeved with a lifting sleeve 22 that rotates synchronously with the ratchet wheel 21. An adjusting rod 23 is provided in the lifting sleeve 22. The upper end of the adjusting rod 23 is formed with an outer wall thread 232, and the inner wall of the upper end of the lifting sleeve 22 is formed with a The inner wall thread 224, the outer wall thread 232 are screwed on the inner wall thread 224, the lower end outer wall of the lifting sleeve 22 is fixed with a hinge seat 221, the inner end of the support arm 24 is hinged on the hinge seat 221, the outer end of the support arm 24 A semi-cylindrical panel brush 25 is hinged, and a groove 231 is formed on the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com