Pipeline outer wall chipping disposal equipment for petroleum pipeline welding

A technology for the outer wall of a pipeline and an oil pipeline is applied in the field of pipeline outer wall debris processing equipment for oil pipeline welding, and can solve the problems of low work efficiency, complex structure, inconvenient use and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

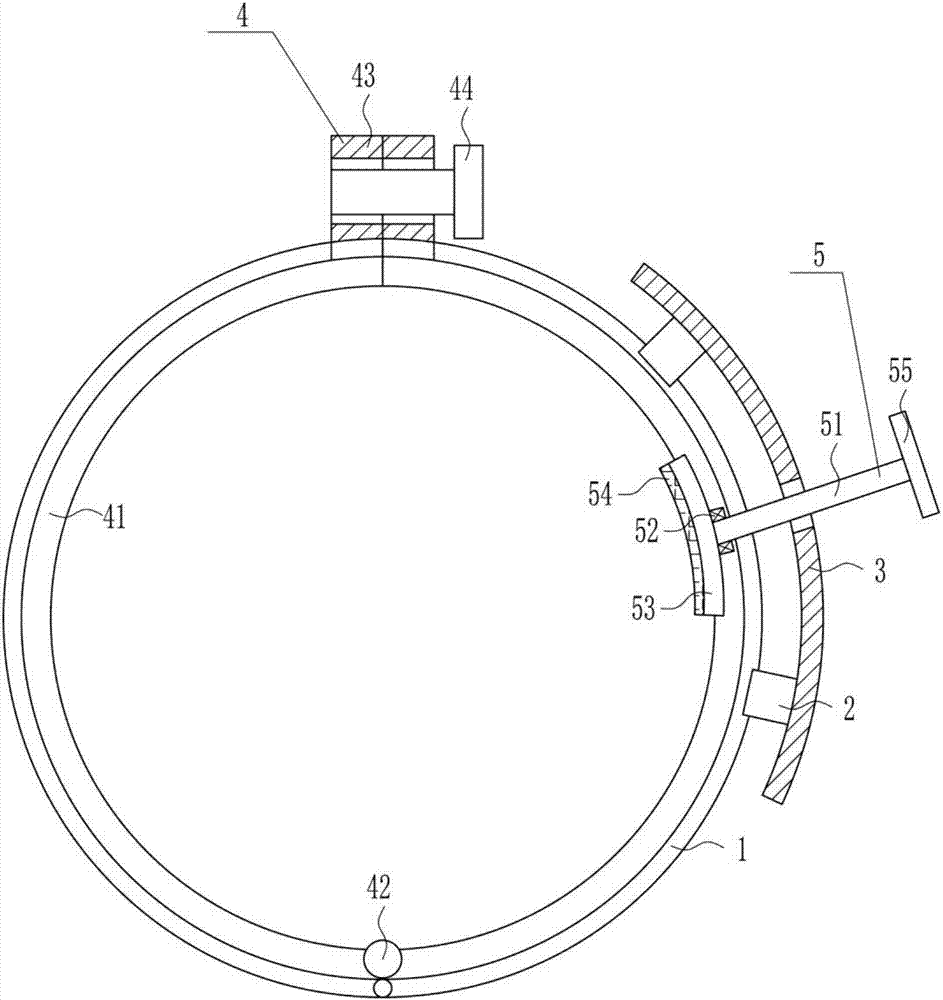

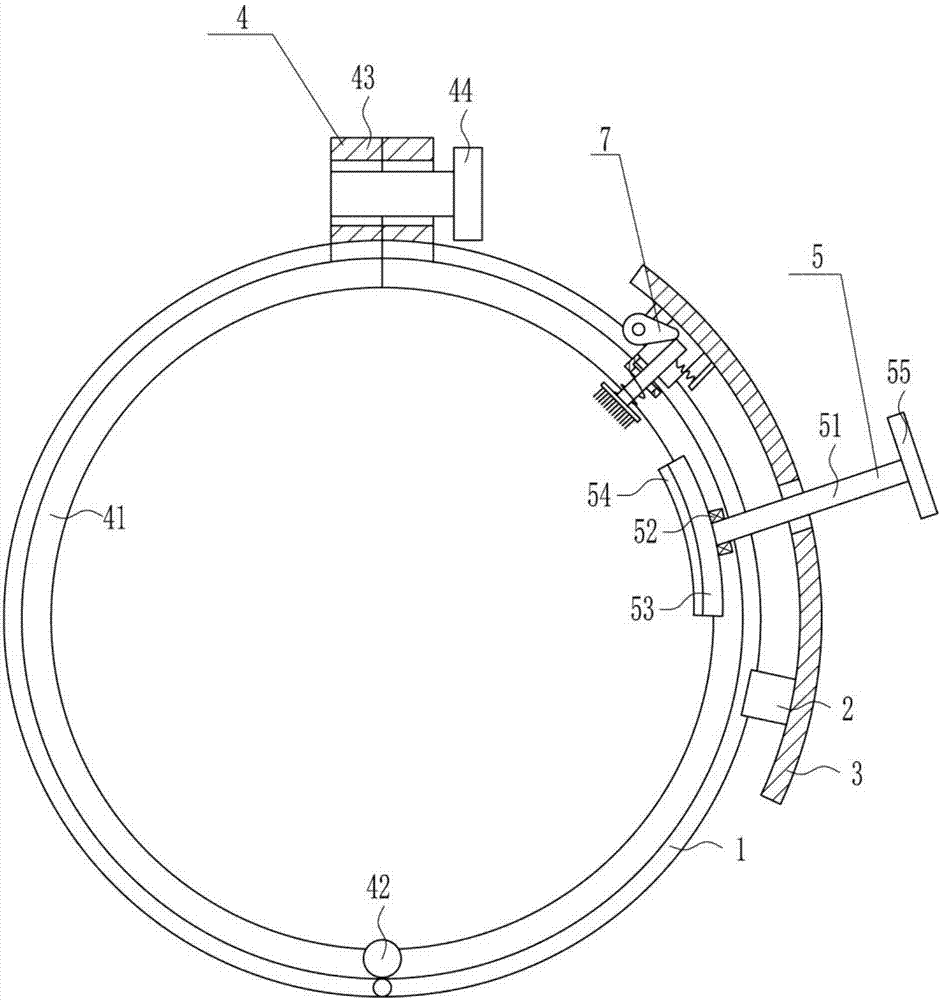

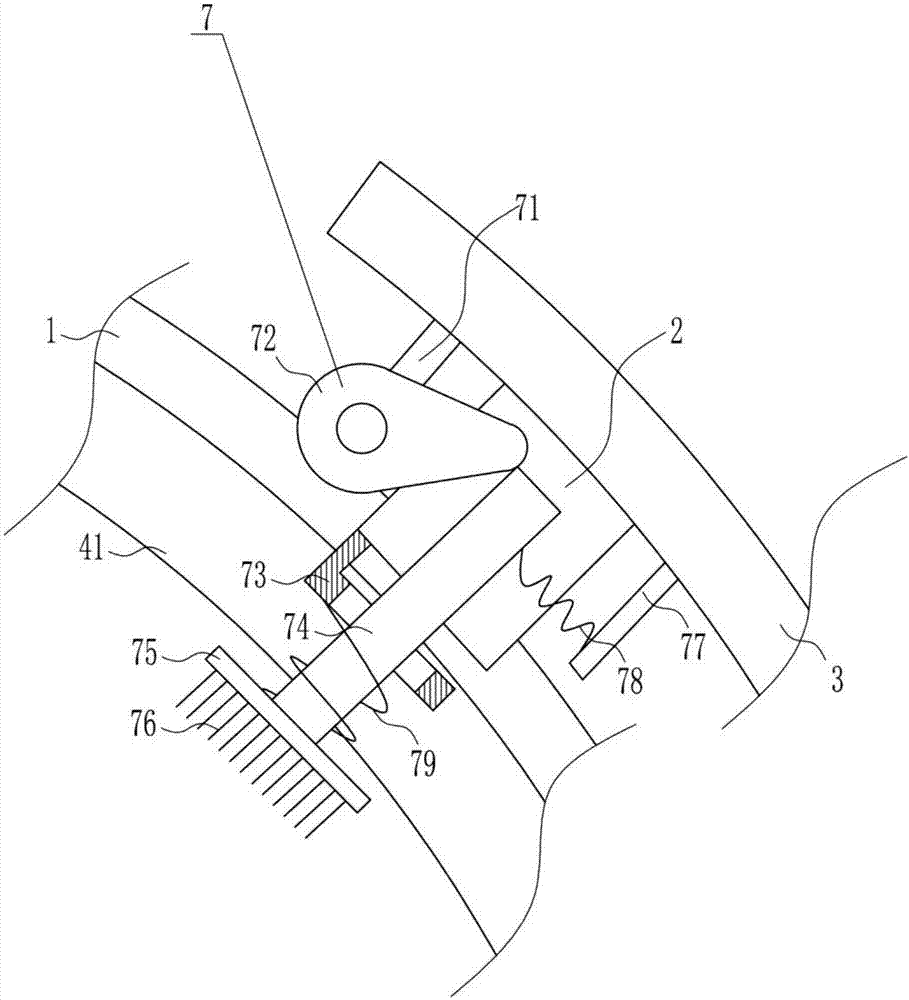

[0037] A kind of pipeline outer wall debris treatment equipment for oil pipeline welding, such as Figure 1-6 As shown, it includes a ring slide rail 1, a slider 2, an arc-shaped movable plate 3, a fixing device 4 and a debris cleaning device 5, and the outside front side bottom of the fixing part of the fixing device 4 is installed with a ring slide rail by way of transfer connection 1. A slider 2 is provided on the annular slide rail 1, and the slider 2 is slidingly matched with the annular slide rail 1. An arc-shaped movable plate 3 is installed on the top of the slider 2, and a debris cleaning device 5 is provided on the arc-shaped fixed plate 813. The cleaning part of the debris cleaning device 5 is located under the front side of the fixing part of the fixing device 4 .

Embodiment 2

[0039] A kind of pipeline outer wall debris treatment equipment for oil pipeline welding, such as Figure 1-6 As shown, it includes a ring slide rail 1, a slider 2, an arc-shaped movable plate 3, a fixing device 4 and a debris cleaning device 5, and the outside front side bottom of the fixing part of the fixing device 4 is installed with a ring slide rail by way of transfer connection 1. A slider 2 is provided on the annular slide rail 1, and the slider 2 is slidingly matched with the annular slide rail 1. An arc-shaped movable plate 3 is installed on the top of the slider 2, and a debris cleaning device 5 is provided on the arc-shaped fixed plate 813. The cleaning part of the debris cleaning device 5 is located under the front side of the fixing part of the fixing device 4 .

[0040] Fixing device 4 comprises arc-shaped fixed block 41, first pin 42, first fixed block 43 and first threaded rod 44, two arc-shaped fixed blocks 41 bottoms are connected by first pin 42, two arc-sh...

Embodiment 3

[0042] A kind of pipeline outer wall debris treatment equipment for oil pipeline welding, such as Figure 1-6 As shown, it includes a ring slide rail 1, a slider 2, an arc-shaped movable plate 3, a fixing device 4 and a debris cleaning device 5, and the outside front side bottom of the fixing part of the fixing device 4 is installed with a ring slide rail by way of transfer connection 1. A slider 2 is provided on the annular slide rail 1, and the slider 2 is slidingly matched with the annular slide rail 1. An arc-shaped movable plate 3 is installed on the top of the slider 2, and a debris cleaning device 5 is provided on the arc-shaped fixed plate 813. The cleaning part of the debris cleaning device 5 is located under the front side of the fixing part of the fixing device 4 .

[0043] Fixing device 4 comprises arc-shaped fixed block 41, first pin 42, first fixed block 43 and first threaded rod 44, two arc-shaped fixed blocks 41 bottoms are connected by first pin 42, two arc-sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap