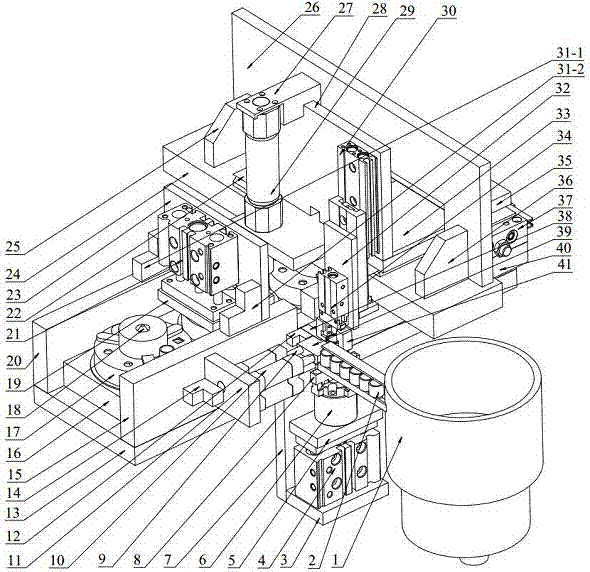

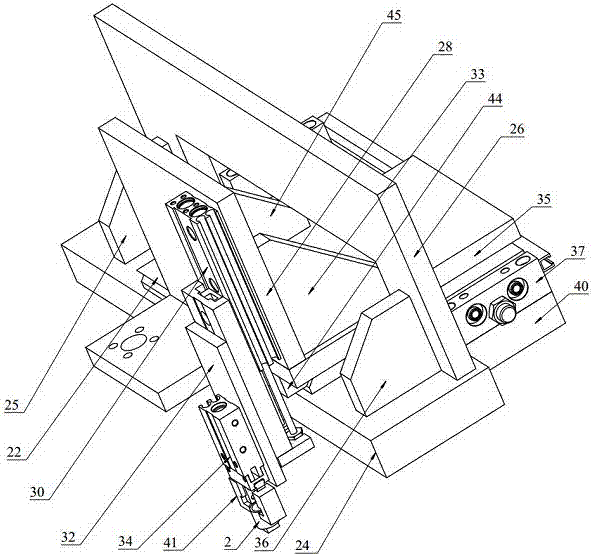

Assembling and correcting device for insulating parts of automobile horns

A technology of calibration devices and insulating parts, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as high defective rate, chaotic production cycle, low assembly production efficiency, etc., and achieve easy and high-precision operation and upgrade The degree of automation and the effect of precise assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

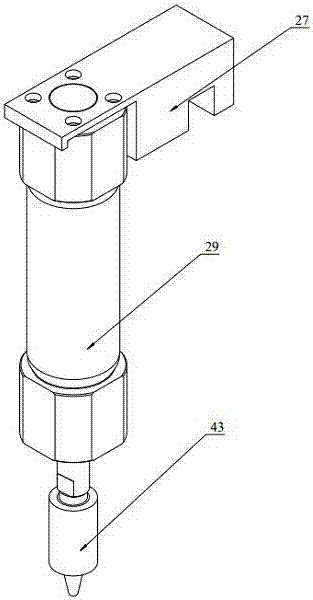

[0032] The initial state of the insulator grasping cylinder 34 is a loose state, the initial state of the insulator Z cylinder 30 is a contracted state, the initial state of the horn housing correction cylinder 29 is a contracted state, and the initial position of the assembly traverse cylinder 37 is to make the horn The shell correction cylinder 29 is located at the correction position, so that the insulating member grabbing cylinder 34 is at the grabbing position, and the end position of the assembly traverse cylinder 37 is such that the insulating member grabbing cylinder 34 is located at the insulating member installation position, and the initial position of the insulating member correcting cylinder 6 is The state is the loosening state, the working state is the clamping and correcting state, the initial state of the insulator correction Z cylinder 4 is that the piston rod baffle is retracted, and its working state is to make the insulator correction cylinder 6 at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com