Sliding device, box corbel assembly component and method for installing box corbels with circular pipe column

A sliding device and sliding component technology, which is applied in the direction of manufacturing tools and hand-held tools, can solve the problems of complex assembly process, heavy construction, and difficult assembly, and achieve the effects of low labor intensity, cost reduction, and convenient assembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

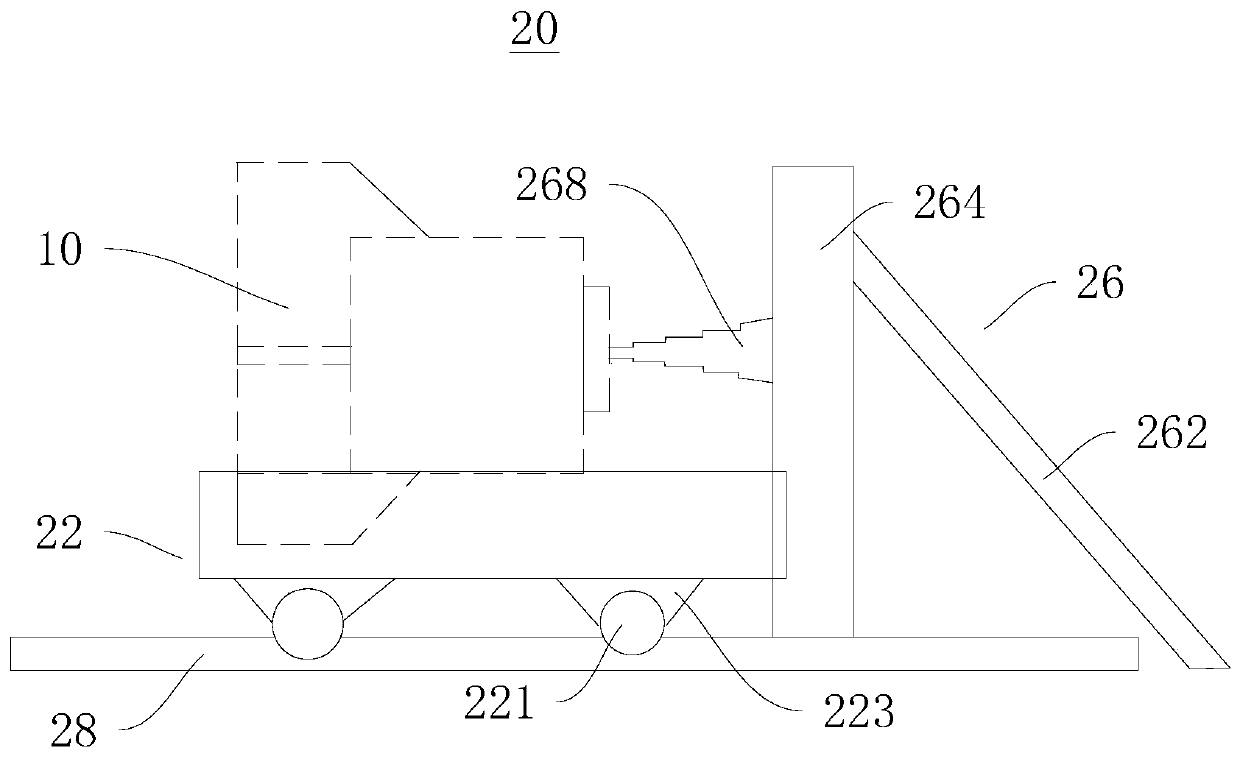

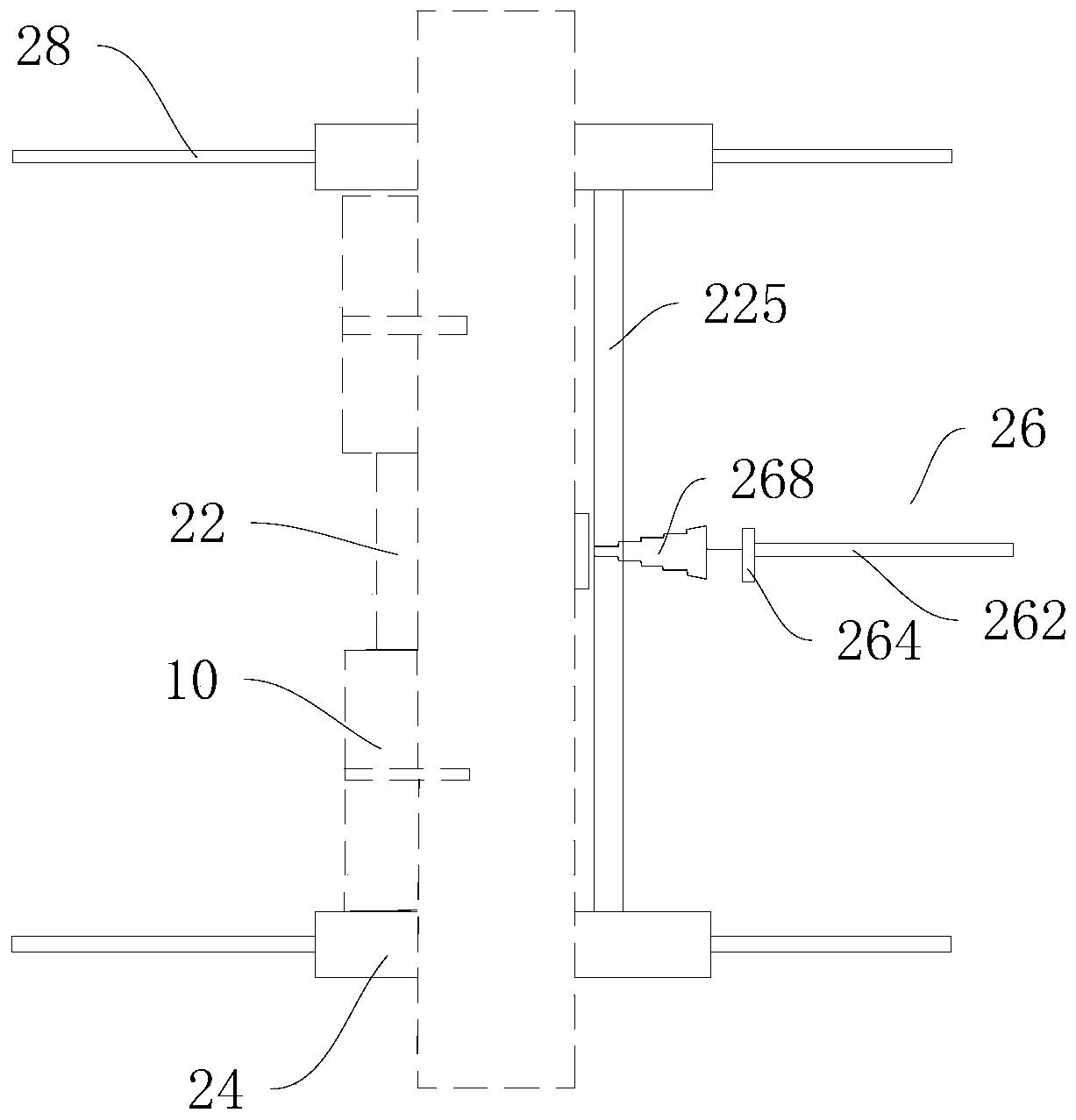

[0046] Such as figure 1 and figure 2 As shown, the sliding device 20 provided by Embodiment 1 of the present invention is used to assemble the box-shaped corbel 10 with the circular pipe column 15. Since the box-shaped corbel 10 is a box-shaped cross corbel, the end of the circular pipe column 15 is provided with The cross groove just matches the structure and size of the box-shaped cross corbel. The sliding device 20 includes a sliding assembly 22 , a supporting platform frame 24 , a positioning push assembly 26 and a slide rail 28 .

[0047] The specific structure of each component of the sliding device 20 and the corresponding relationship among them will be described in detail below.

[0048] Firstly, the slide assembly 22 is introduced in detail. The slide assembly 22 can slide back and forth along the slide rail 28 on the workbench to complete the assembly of the box-shaped corbel 10 and the round pipe column 15 arranged thereon. The specific structure is as follows. ...

Embodiment 2

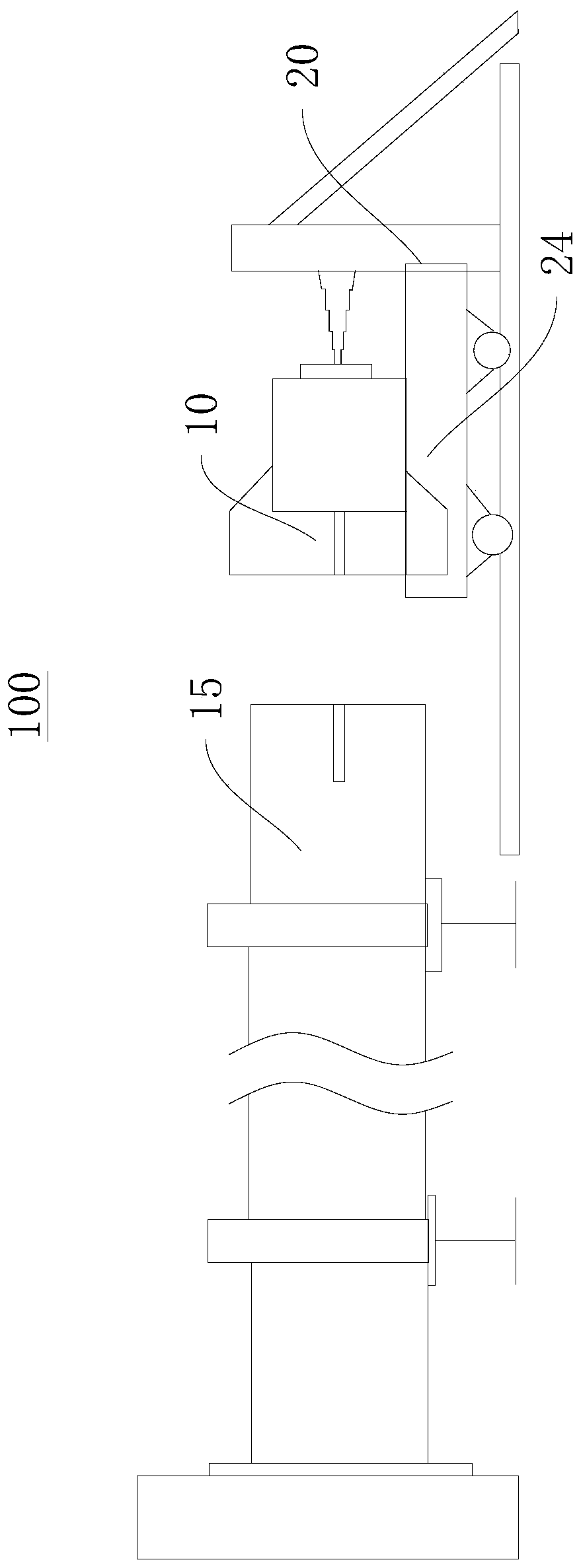

[0067] Embodiment 2 of the present invention provides a box-shaped corbel assembly assembly 100, including a box-shaped corbel 10 and the sliding device 20 provided in Embodiment 1. Please refer to image 3 and Figure 4 As shown, the specific description is as follows:

[0068] The box-shaped corbel 10 is a box-shaped cross corbel. First, the box-shaped corbel 10 is fixedly arranged on the support platform frame 24. Specifically, the box-shaped corbel 10 includes opposite cross fitting ends and abutting ends, wherein , the cross fitting end can cooperate with the cylindrical pipe column 15 , and the abutting end abuts against the positioning push assembly 26 .

[0069] Optionally, the round pipe column 15 is a steel structure round pipe column with a cross groove at its end, and its structure and size are just matched with the box-shaped corbel 10 .

[0070] By fixing the box-shaped corbel 10 on the support platform frame 24 of the sliding device 20, the movement of the box...

Embodiment 3

[0072] Embodiment 3 of the present invention provides a method for installing a box-shaped corbel 10 on a cylindrical column 15, using the sliding device 20 provided in Embodiment 1. The specific description is as follows:

[0073] The method for installing the box-shaped corbel 10 on the cylindrical column 15 includes:

[0074] Preparatory steps: positioning the round tube column 15 on the workbench, specifically, fixing the round tube column 15 on the workbench with a section steel limit, and the cross-groove end of the round tube column 15 can be elevated.

[0075] Leveling step: center and level the box-shaped corbel 10 set on the sliding device 20 and the round pipe column 15, specifically, set the slide rail 28 on the workbench correspondingly, and fix the box-shaped cross corbel on the sliding device 20 On the supporting platform frame 24, make the cross groove centering and leveling of the box type cross corbel and the round pipe column 15.

[0076] Assembly steps: op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com