Width-adjustable erecting mechanism and method for mechanized bridge

A width and sub-frame technology, which is applied in the field of mechanized bridge erection mechanism, can solve the problems of lack of drive bridge span, low operating efficiency, and difficult adjustment, and achieve the effect of improving work efficiency and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

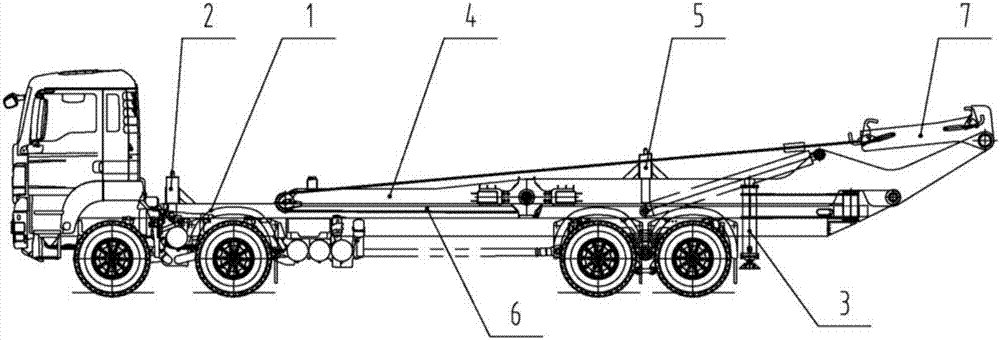

[0036] Embodiment 1: see attached Figures 1 to 13 , an erecting mechanism for a width-adjustable mechanized bridge, comprising: a chassis vehicle, a sub-frame 1, a front transverse bridge spreading mechanism 2, a stabilizing outrigger assembly 3, an erecting frame assembly 4, a rear transverse spreading bridge mechanism 5, folding Pull rod 6, tongue arm assembly 7, hydraulic system and electrical control system;

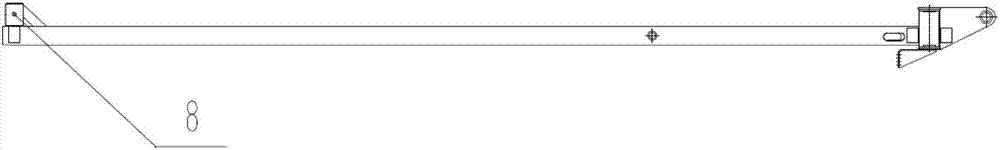

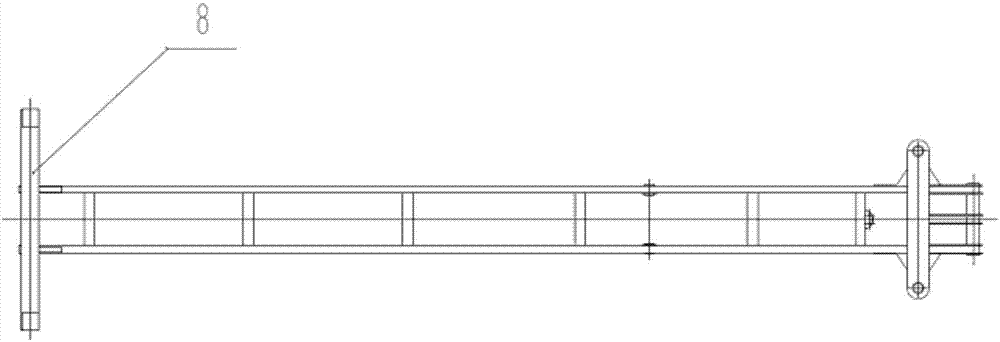

[0037] The sub-frame 1 is a side-beam frame structure, which is directly fixed on the girder of the chassis vehicle. The upper part of the front end of the sub-frame 1 is provided with an outer arm 8 of the front transverse bridge extension mechanism along the transverse direction;

[0038] The front transverse bridge expansion mechanism 2 includes: the front transverse bridge expansion telescopic arm 9 and the telescopic oil cylinder 10; the two front transverse bridge expansion telescopic arms 9 are symmetrically installed in the outer arm 8 of the front transvers...

Embodiment 2

[0045] Embodiment 2: see attached Figures 14 to 21 , a method for erecting a width-adjustable mechanized bridge, which uses the erection mechanism of a width-adjustable mechanized bridge as described in Embodiment 1, comprising the following steps:

[0046] Step 1: Lock the bridge span on the tongue arm assembly 7, transport the erection mechanism and bridge span of the width-adjustable mechanized bridge to the predetermined erection position through the chassis vehicle, and complete the bridge erection preparation;

[0047] Step 2: The left outrigger 14 and right outrigger 12 of the stabilizing outrigger assembly 3 swing into place and reliably support the ground, loosen the locking bridge mechanism on the tongue-shaped arm assembly 7, and then operate the front transverse bridge spreading mechanism 2 and the rear The horizontal bridge extension mechanism 5 acts synchronously with the horizontal stabilizer on the bridge span, adjusts the width of the bridge span to the requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com