Extractor hood

A range hood and range hood technology, applied in the field of kitchen appliances, can solve problems such as affecting the health of users, affecting the overall appearance, bumping the user's head, etc., and achieving the effects of simple structure, good effect of preventing oil fume escape, and better appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

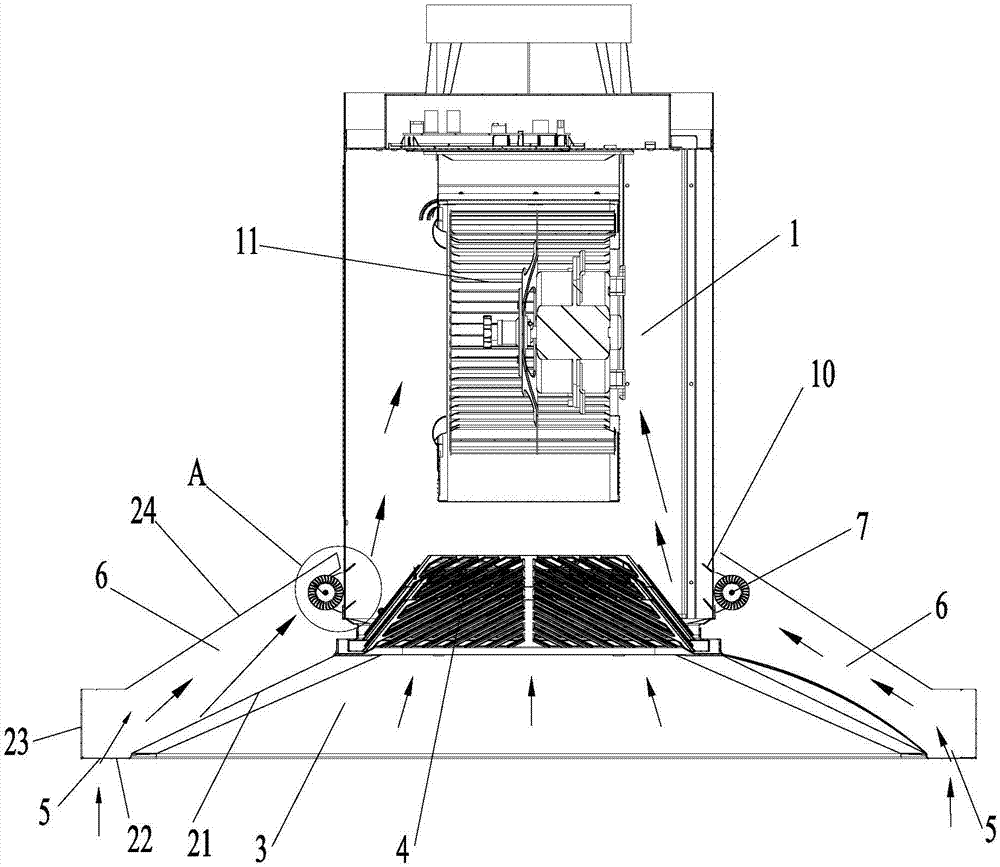

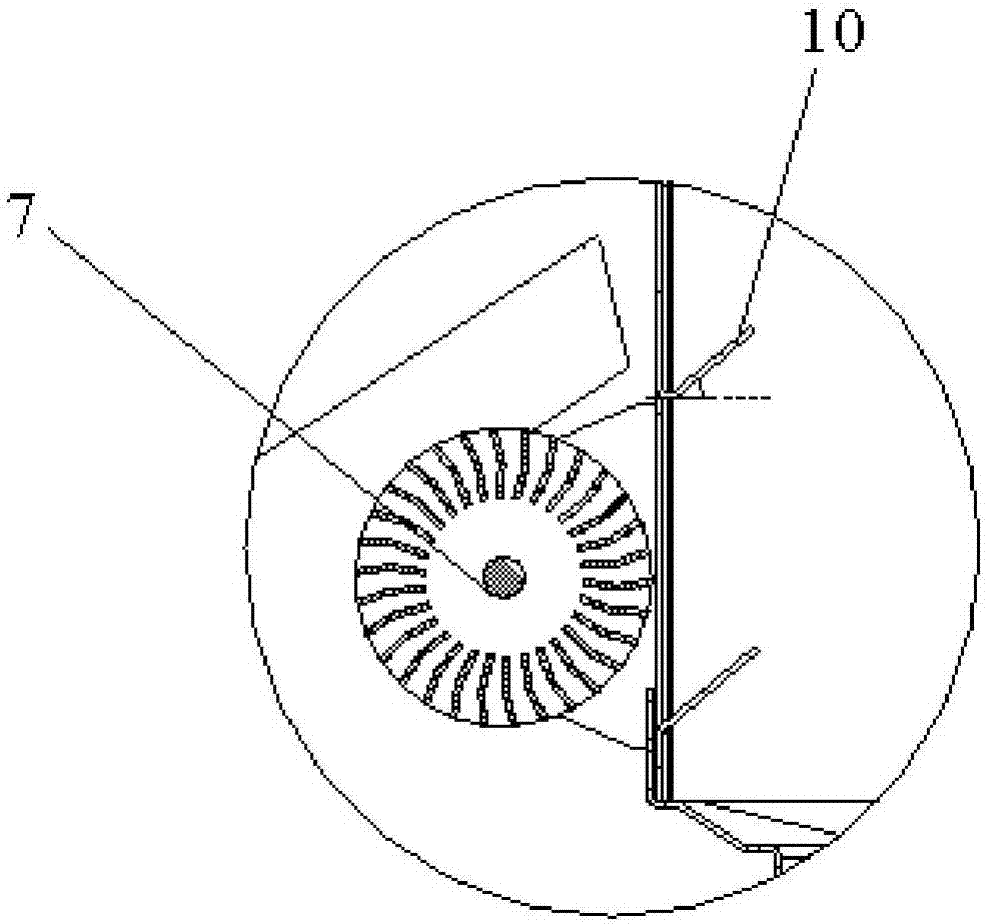

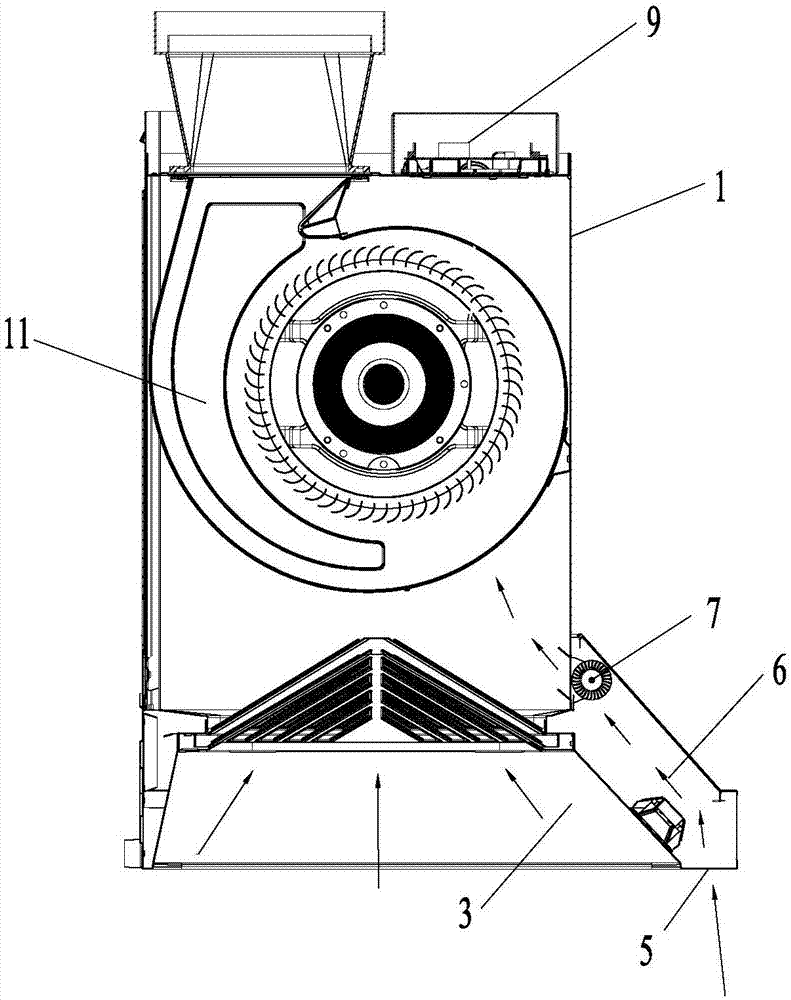

[0028] Such as Figure 1 to Figure 3 as shown ( figure 1 and image 3 The arrow in the arrow indicates the flow direction of the oil fume), this embodiment provides a range hood, which includes a fume collecting hood 2 and a wind cabinet 1 arranged above the fume collecting hood 2, and the fume collecting hood 2 is recessed upwards to form a smoke collecting chamber 3. The smoke collecting cavity 3 is provided with a main air inlet 4, and the main air inlet 4 communicates with the air inlet of the wind cabinet 1, and the wind cabinet 1 is provided with a main fan 11. The lower end of the smoke collecting hood 2 is provided with an auxiliary air inlet 5 located outside the smoke collecting chamber 3, and the smoke collecting hood 2 is provided with an auxiliary smoke exhaust channel 6 communicating with the auxiliary air inlet 5. An exhaust device for extracting oil fumes in channel 6. The ventilation device is preferably but not limited to an auxiliary blower 7 arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com