Motor temperature control device for infrared band test system

A test system and infrared band technology, which is applied in the aerospace field, can solve the problems of reduced measurement accuracy of the infrared band test system, and achieve the effect of ensuring measurement accuracy and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

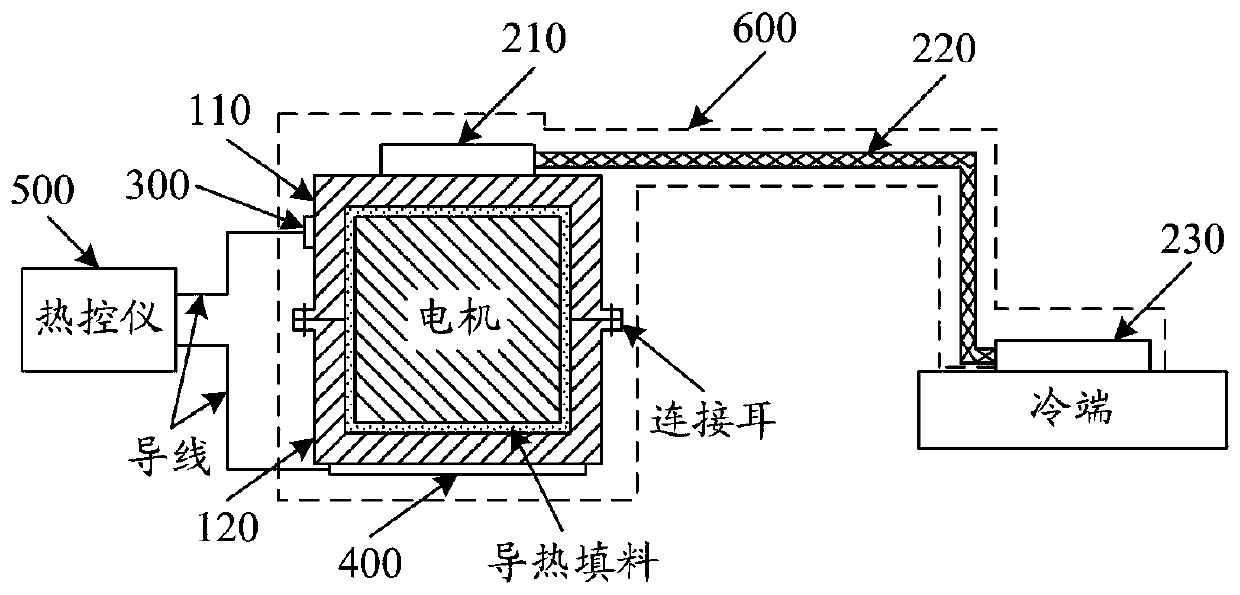

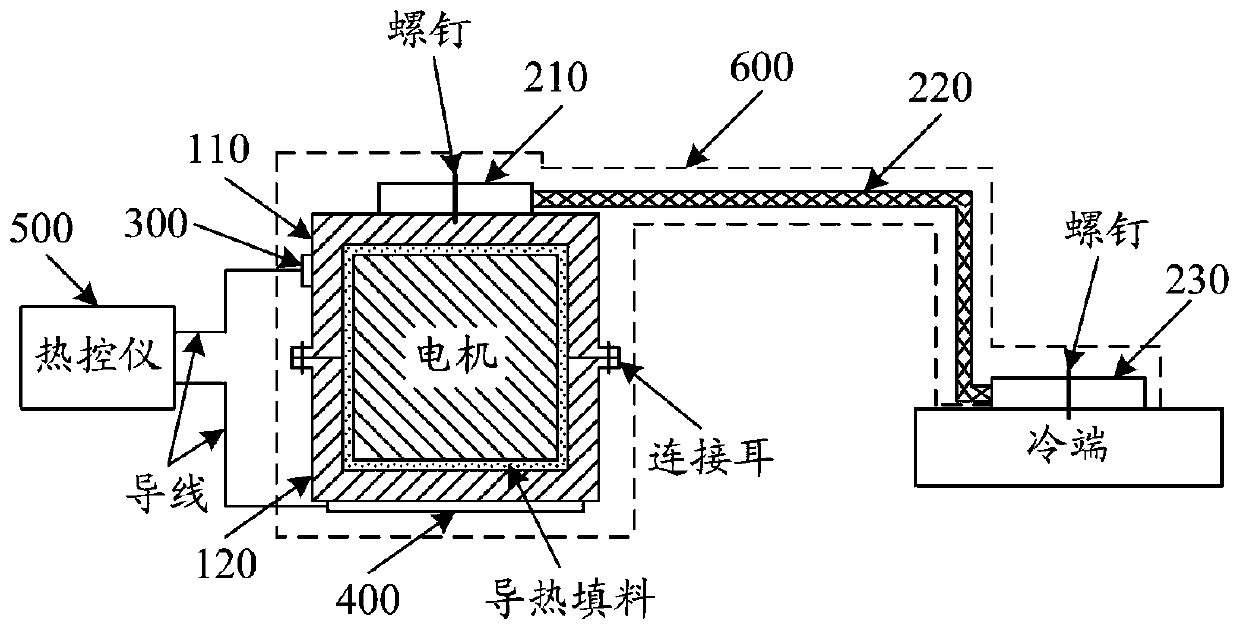

[0015] In one of the examples, as figure 1 As shown, the motor temperature control device used in the infrared band test system includes a heat conduction cable mounting bracket, a heat conduction cable, a temperature measurement sensor 300, a heating plate 400, a thermal controller 500 and a multilayer heat insulation assembly 600,

[0016] The thermal cable mounting bracket includes an upper housing 110 and a lower housing 120 that match the shape and size of the motor, and the upper housing 110 and the lower housing 120 have connecting ears, and the upper housing 110 and the lower housing 120 pass through the connecting ears Sealed connection, between the motor and the upper casing 110 and the lower casing 120 is filled with thermally conductive fillers;

[0017] The heat conduction cable includes a heat conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com