Industrial dust remover

An industrial dust collector and water tank technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of slow dust collection, less improvement of workshop air, inducing various diseases, etc., to enhance the ability to absorb dust. Ability, easy maintenance and repair, improve the effect of filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

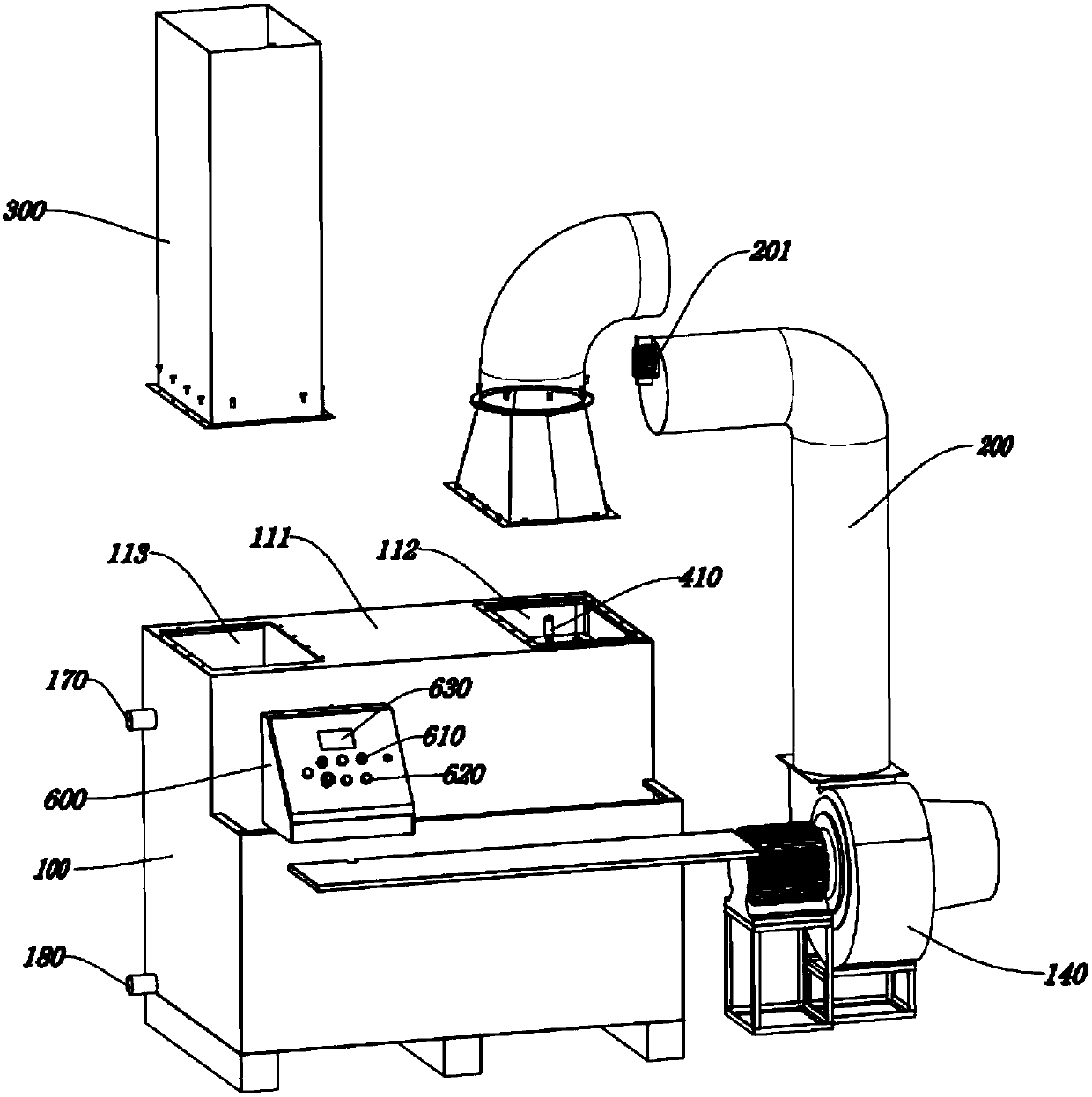

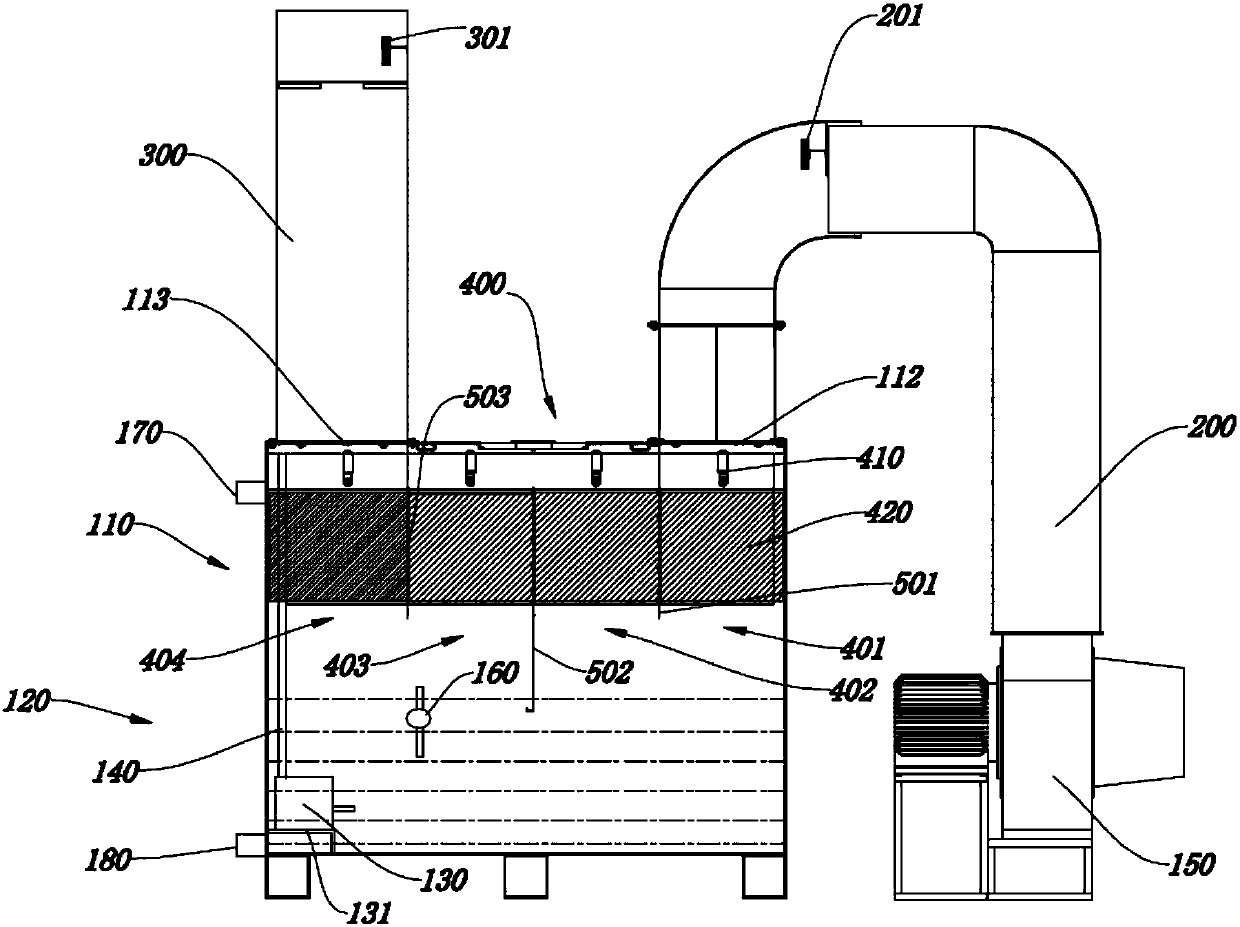

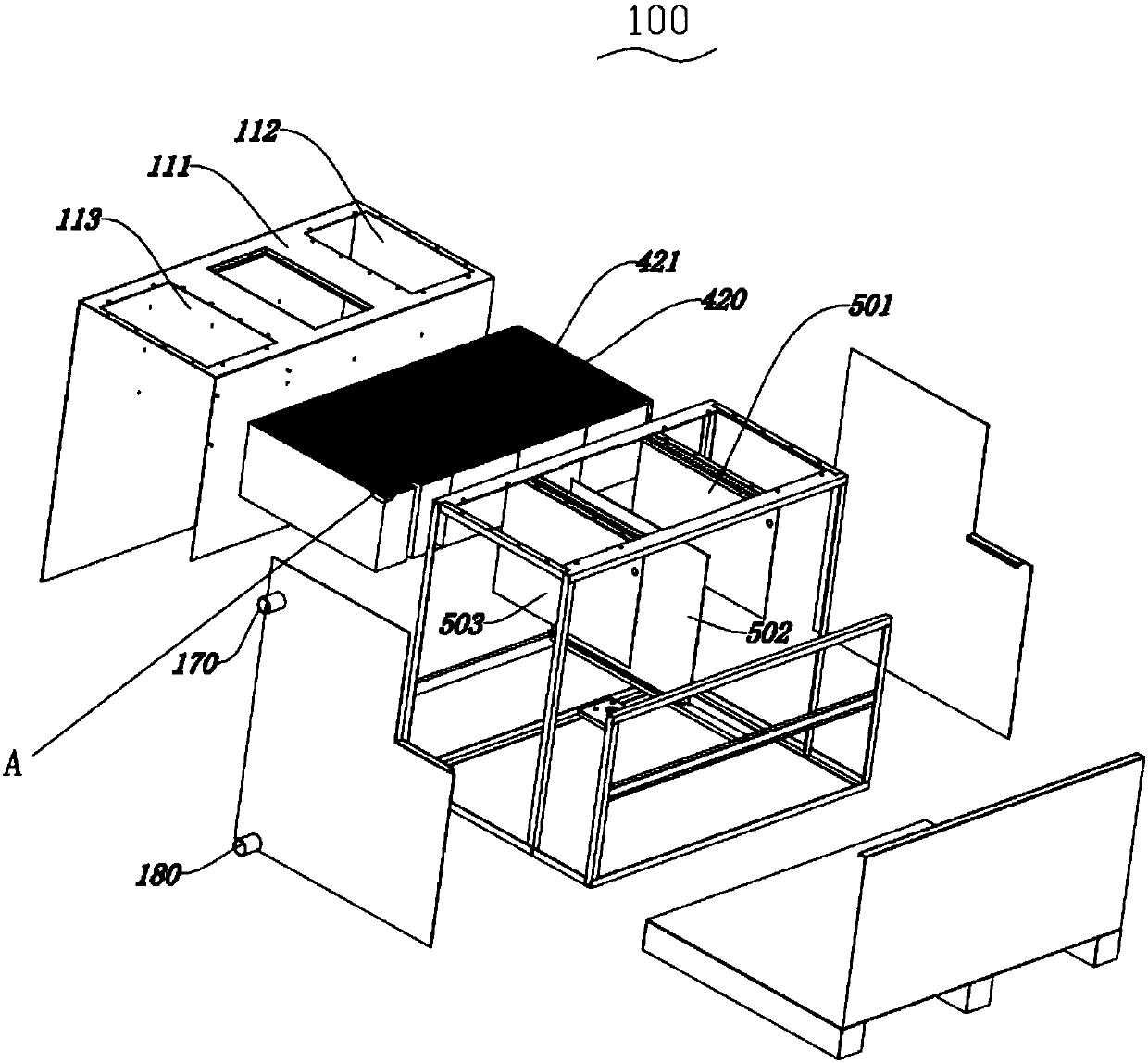

[0022] like Figure 1-3 As shown, in an embodiment of the present invention, an industrial dust collector is provided, which is used for dust removal and purification of air in a production workshop. The industrial dust collector includes a water tank 100, an air inlet pipeline 200 and an air outlet pipeline 300 respectively connected to the water tank 100, and a filter assembly 400 arranged in the water tank 100, and the filter assembly 400 includes a spray piece 410 And / or the filter block 420 , the spray element 410 is arranged above the filter block 420 , and a plurality of passages 421 passing through the filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com