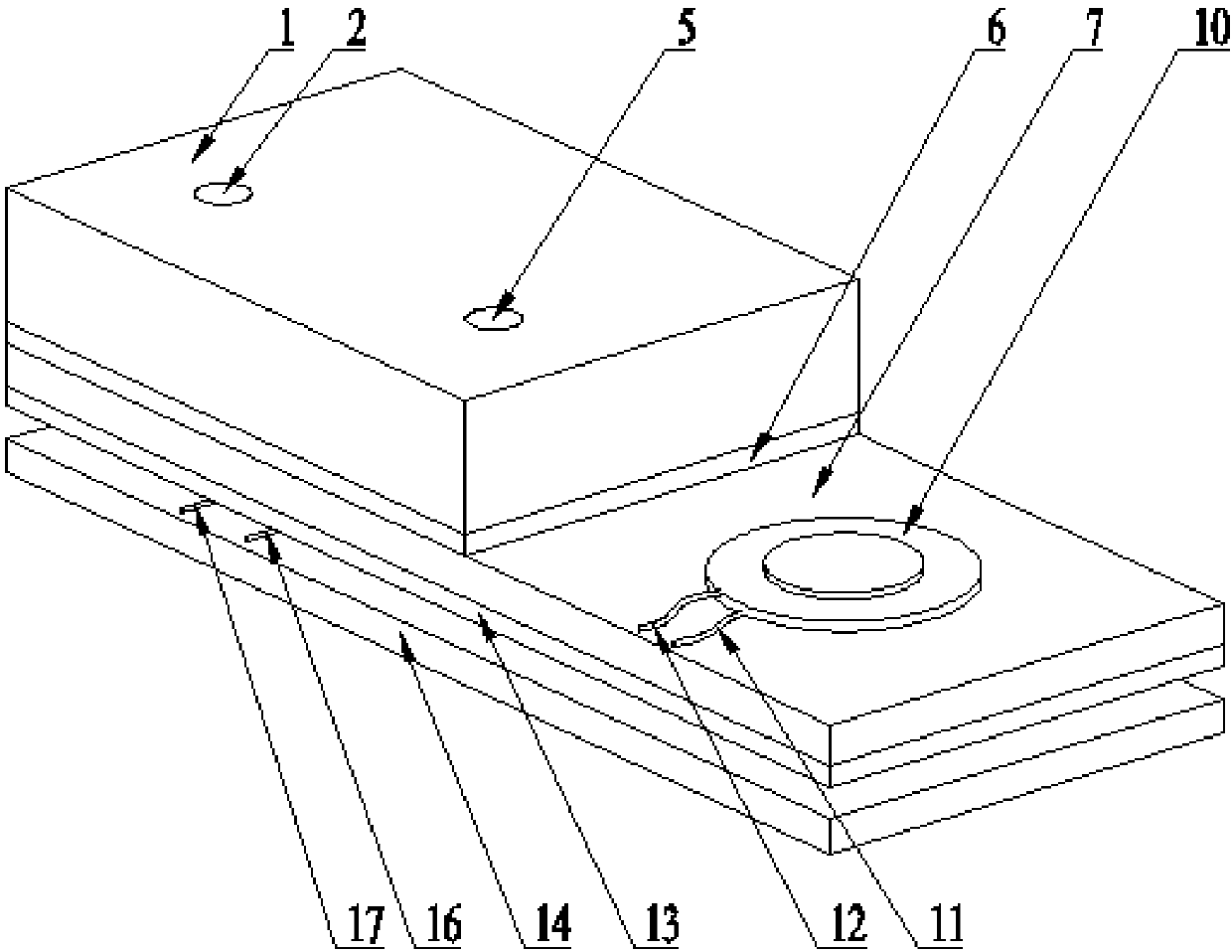

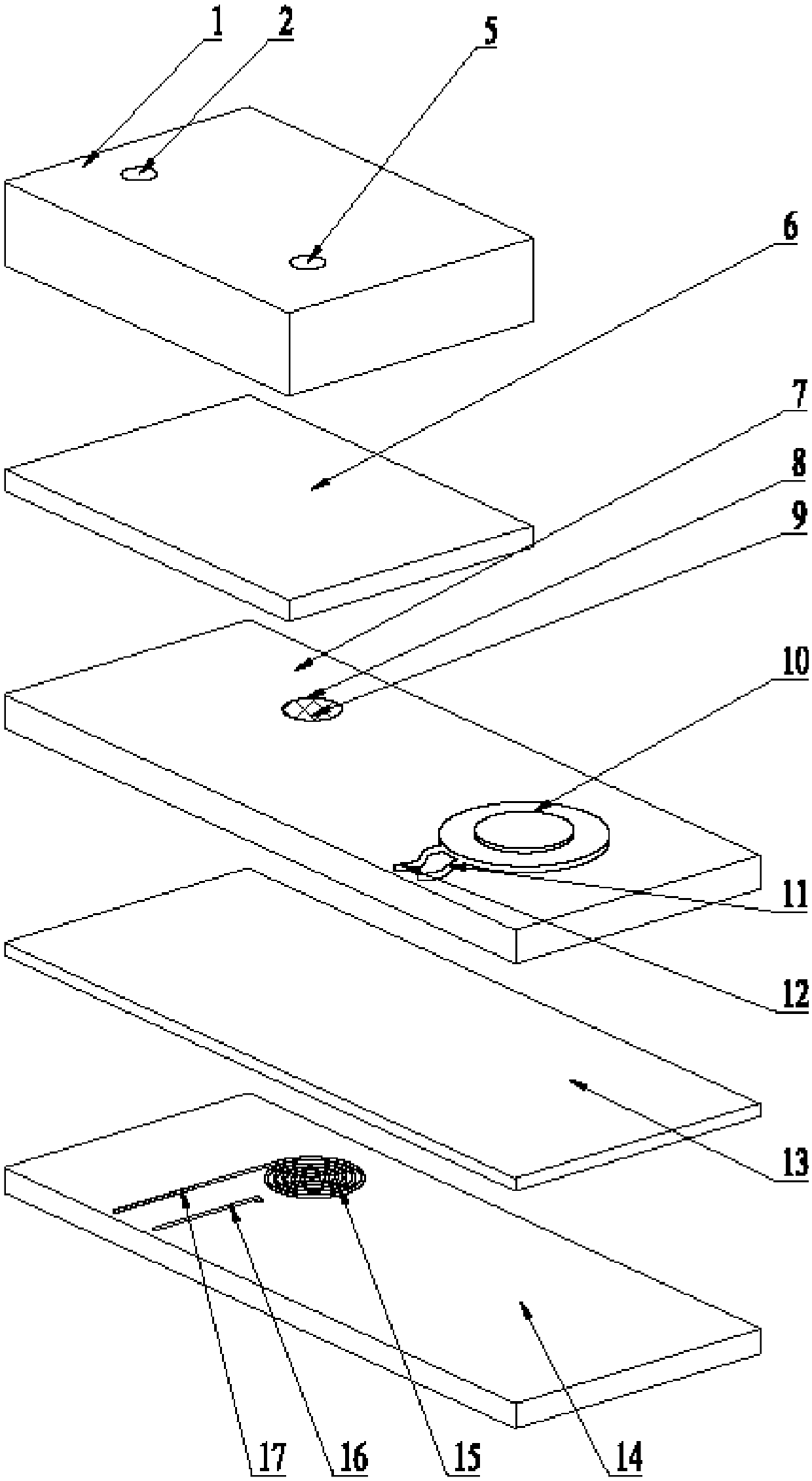

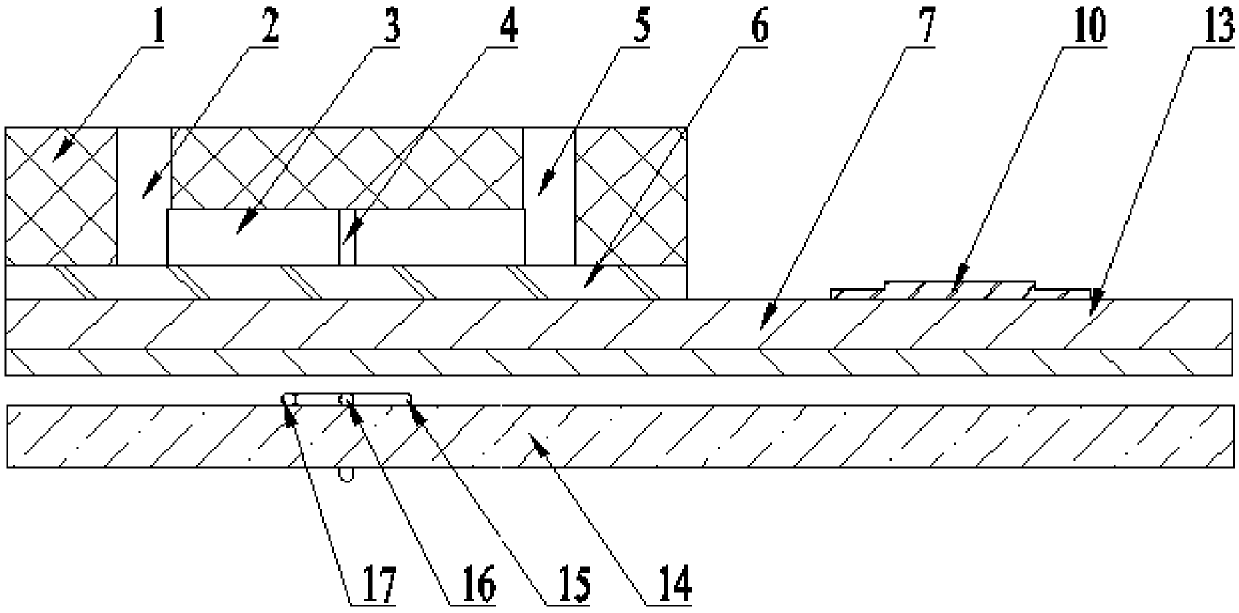

Particle capturing and releasing device based on bulk acoustic wave excitation and moving bubbles

A technology for releasing devices and air bubbles, which is applied in the direction of machines/engines, liquid variable displacement machines, chemical instruments and methods, etc. It can solve the problems of complex manufacturing process, particle damage, and large volume, and achieve short response time and low production cost. , the effect of easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The microfluidic upper chip 1 in the present invention adopts SU-8 type negative photoresist to make a positive mold, and polydimethylsiloxane (PDMS) injection molding process is used for manufacturing. The specific process flow is as follows:

[0056] (a) with Figure 13 , select the silicon substrate I22 as the substrate, wash it with deionized water, and dry it on a rubber drying table at a temperature of 110°C;

[0057] (b) with Figure 14 , spin-coat a layer of SU-8 glue 23 on the silicon substrate I22, the thickness of the glue layer is 50μm-100μm, use the glue drying table for pre-baking, first at a temperature of 65°C for 35min, and then at a temperature of 95°C The drying time is 30-90min (related to the thickness of the adhesive layer, the greater the thickness, the longer the drying time), then naturally cool to solidify the SU-8 adhesive 23, which is a negative photoresist;

[0058] (c) with Figure 15 , place the mask plate 24 on the surface of the cured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com