Needle grinding machine

A needle grinding machine and needle grinding technology, which is applied to the grinding frame, the machine tool suitable for grinding the edge of the workpiece, the grinding bed, etc., can solve the problems of low grinding efficiency and inability to flexibly adjust the angle of the workpiece, and achieve improved The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

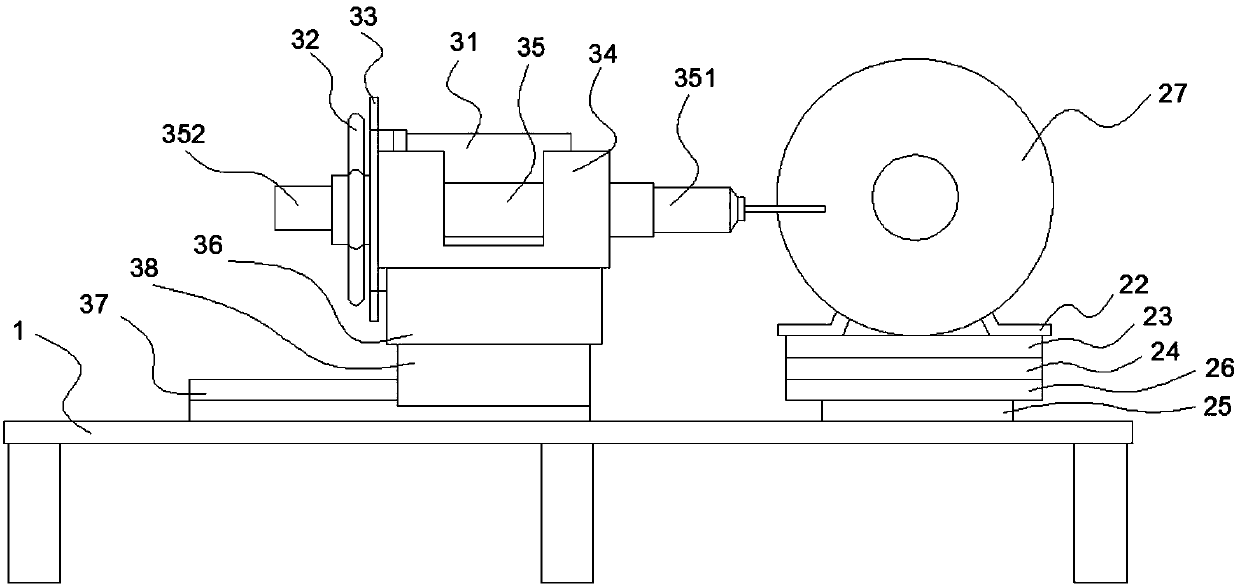

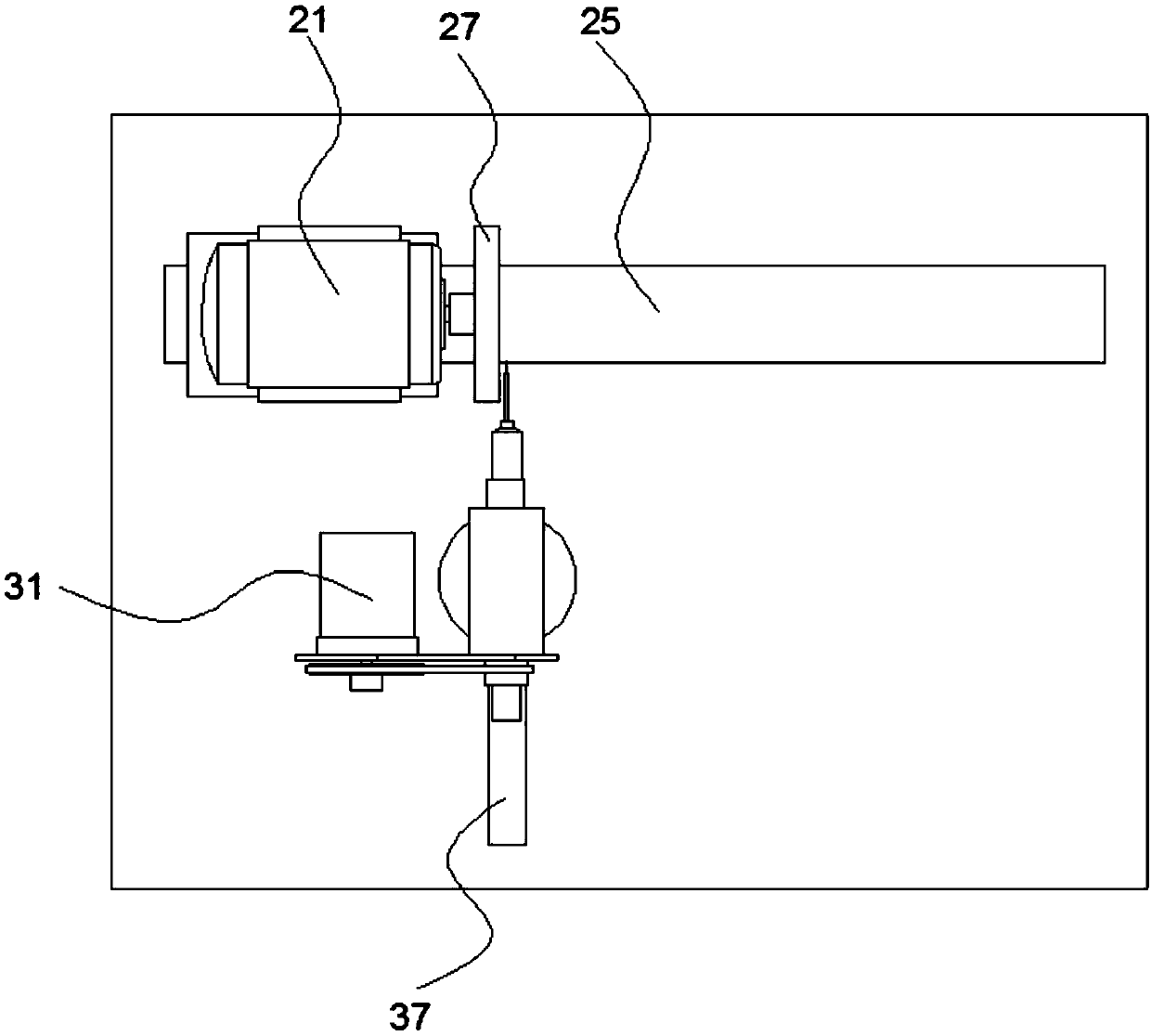

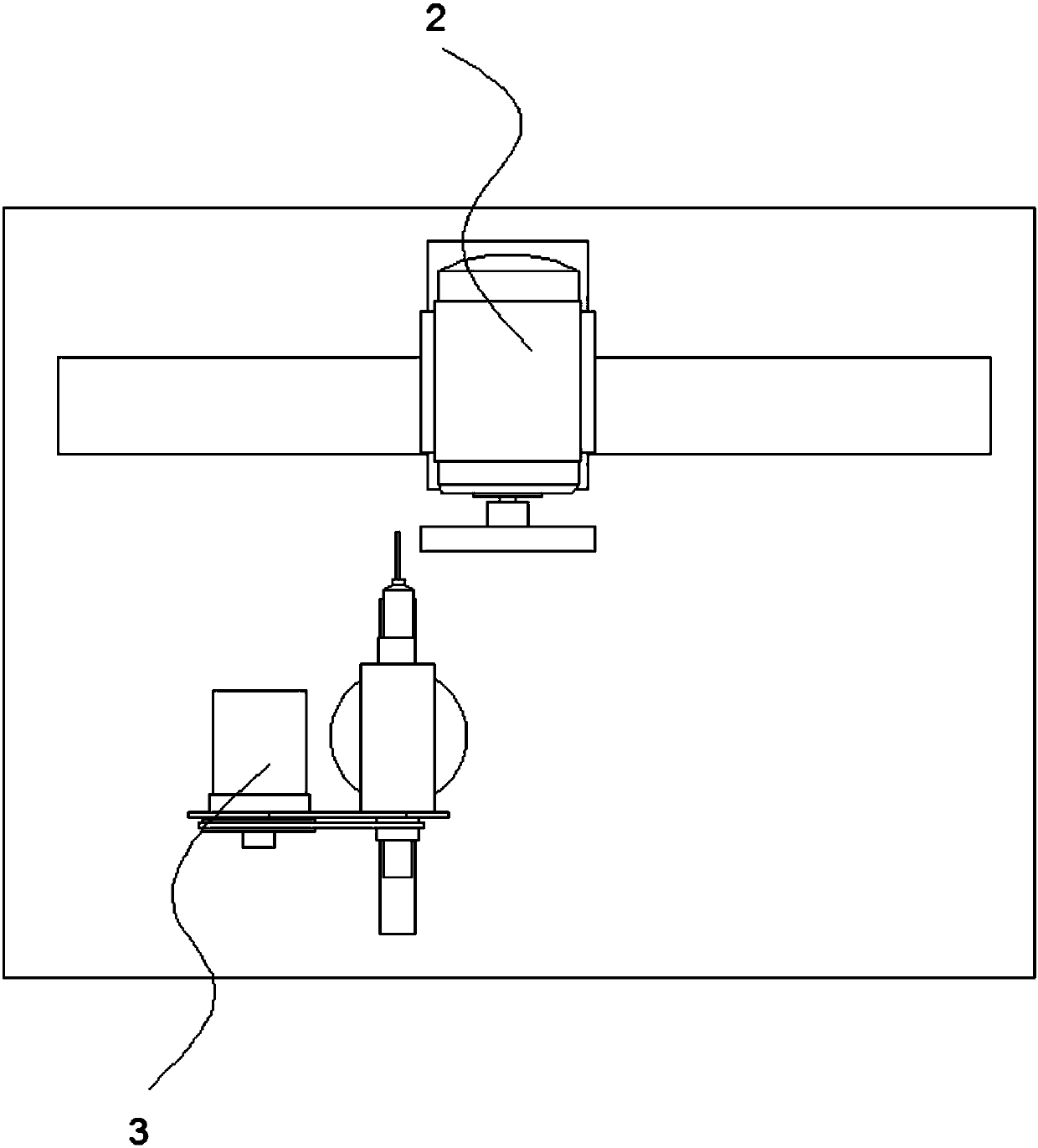

[0023] see figure 1 , which is a side view of the needle grinding machine of the present invention. The needle grinding machine of the present invention includes a base 1, a grinding wheel assembly 2 and a clamp assembly 3; the grinding wheel assembly 2 includes a first motor 21, a motor fixing frame 22, a motor bracket 23, a first indexing plate 24, a first Guide rail 25, first slide block 26 and emery wheel 27, described fixture assembly 3 comprises second motor 31, belt 32, motor support 33, fixture holder 34, bearing, grinding pin fixture 35, second index plate 36, the second Two guide rails 37 and a second slide block 38; the first guide rail 25 and the second guide rail 37 are specifically ball guide rails.

[0024] The first guide rail 25 is fixed on the base 1, the first slider 26 is movably arranged on the first guide rail 25, the first indexing plate 24 includes a base and is arranged on the A rotating disk on the base that can rotate relative to the base, the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com