Shredding device for waste paper making

A technology for paper making and shredding from waste paper, which is applied in the field of paper making equipment and can solve the problems of easy blockage of materials and uneven paper shredding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail through specific embodiments below.

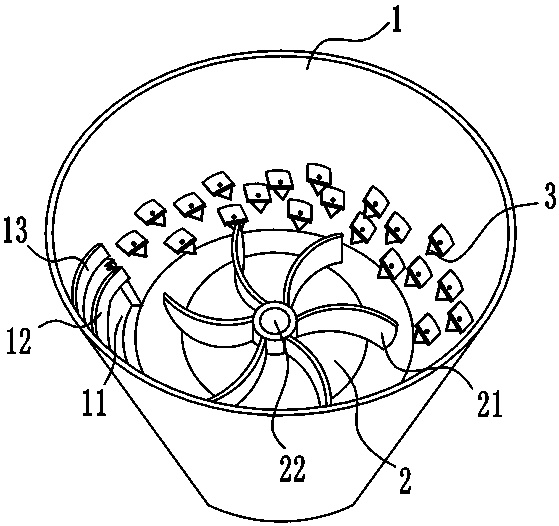

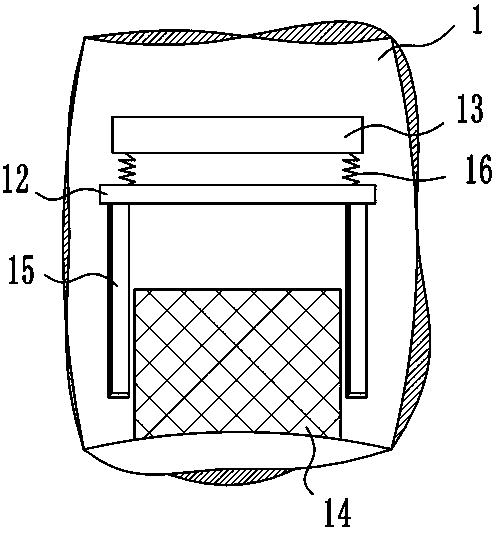

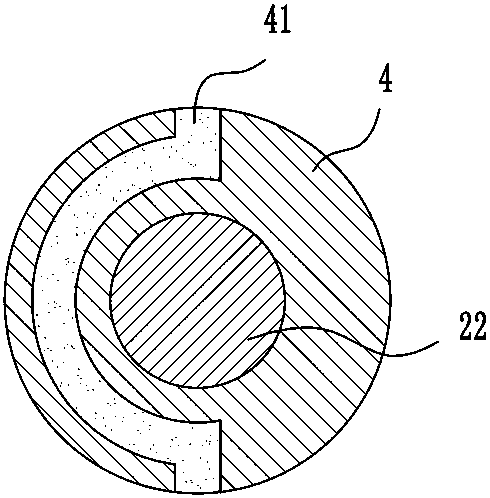

[0029] The reference signs in the accompanying drawings of the specification include: barrel 1, driving impeller 2, cutter 3, switch cover 4, mounting seat 5, discharge port 11, push block 12, spring seat 13, filter screen 14, guide groove 15 , Extension spring 16, driving wheel sheet 21, impeller shaft 22, copper sheet 41, I-shaped post 51, retaining sheet 52, and sheet 53.

[0030] Paper shredders for waste paper making, such as figure 1 , figure 2 and image 3 Shown: including barrel 1, barrel 1 is fixed on the bracket by bolts, a conveyor belt for continuous transmission is set above barrel 1, an intermittently energized electromagnet is installed in the inner bottom of barrel 1, and the inner bottom of barrel 1 The wall is provided with an energizing circuit for energizing the electromagnet. The wire of the energizing circuit has a gap for de-energizing the energizin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com