Construction method of drainage pipe crossing seawall

A construction method and drainage pipe technology, which are applied in water conservancy projects, sewer pipeline systems, excavation, etc., can solve problems such as difficulty in ensuring the quality of steel pipes and transportation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings.

[0059] The invention provides a method for constructing a drainage pipe crossing a seawall, the method comprising the following steps:

[0060] (A) Build cut-off walls and cofferdams inside the seawall, and excavate trenches.

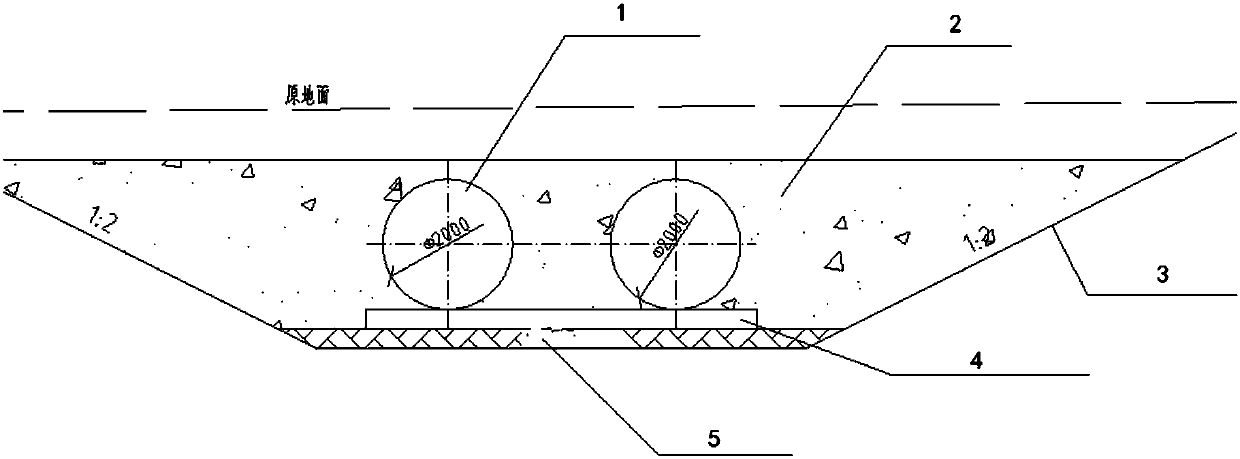

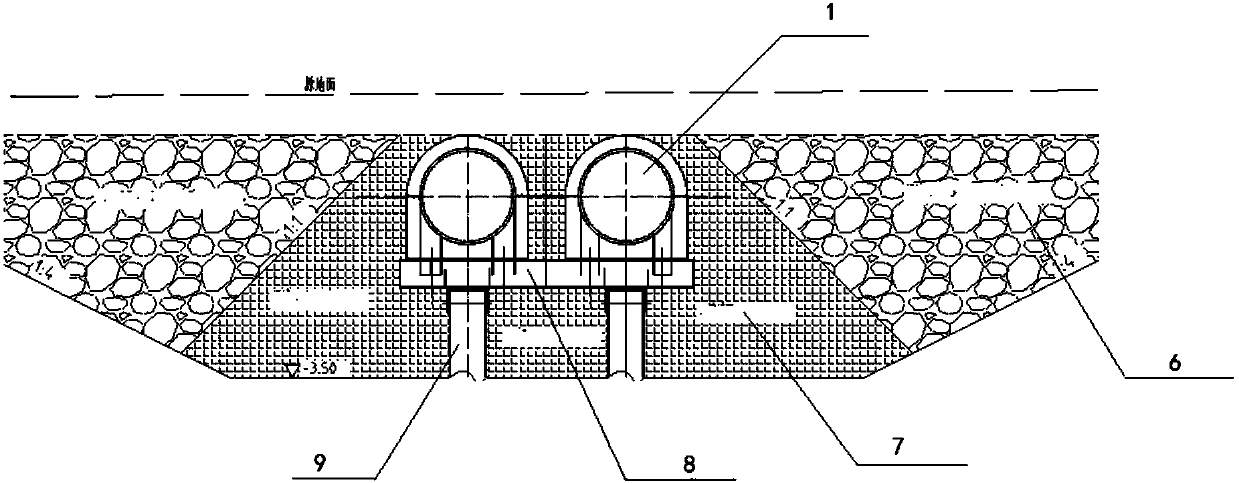

[0061] The part of the trench without pile foundation is excavated by the back method of the excavator, and the slope ratio is 1:1.5-2.5, preferably 1:2 (such as figure 1 As shown), the pile foundation part of the trench is excavated by a grab dredger, the excavation depth is -3.0 to -4.5 meters, preferably about -3.5 meters, and the slope is 1:3-5, preferably 1:4 (such as figure 2 shown).

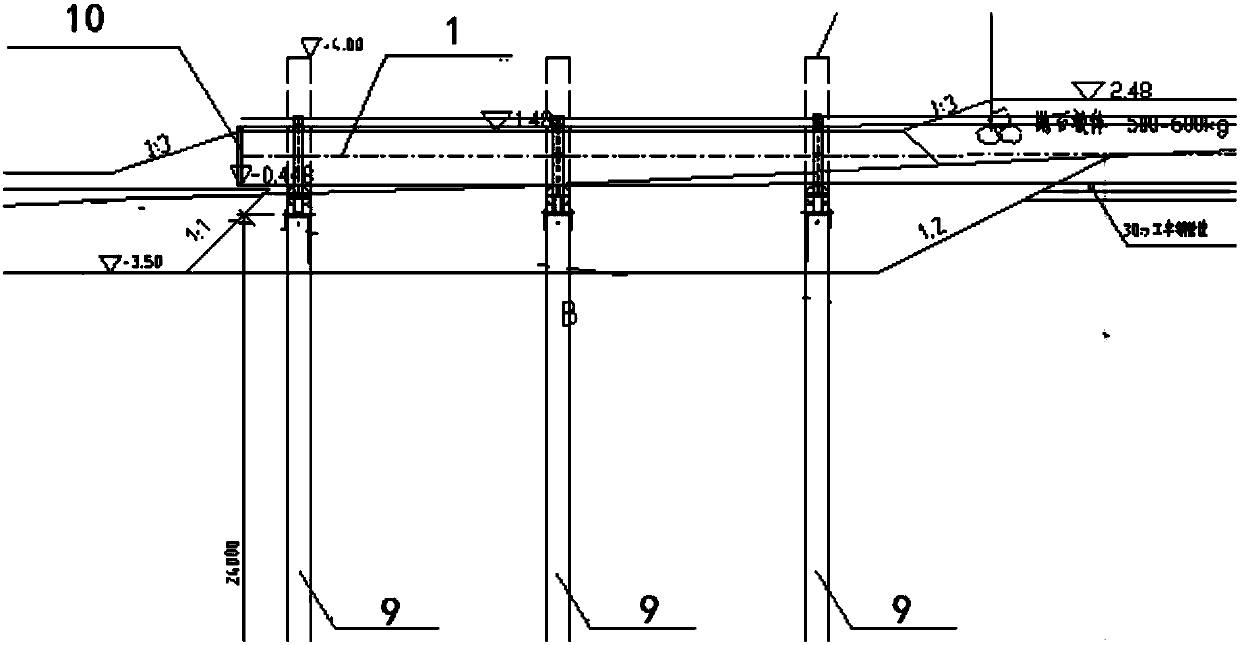

[0062] (B) A steel pipe pile 9 is driven into the front end of the drainage pipe, and a steel beam 8 for placing the drainage pipe is arranged on the upper part of the steel pipe pile 9 .

[0063]Preferably, steel pipe pile foundations are used at the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com